Axial-flow blower

An axial flow fan, fan technology, applied in mechanical equipment, gas turbine devices, machines/engines, etc., can solve problems such as difficult to master and operate, poor work reliability, large test equipment, etc., and achieve uniform and equal axial force. The effect of equalizing and improving working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

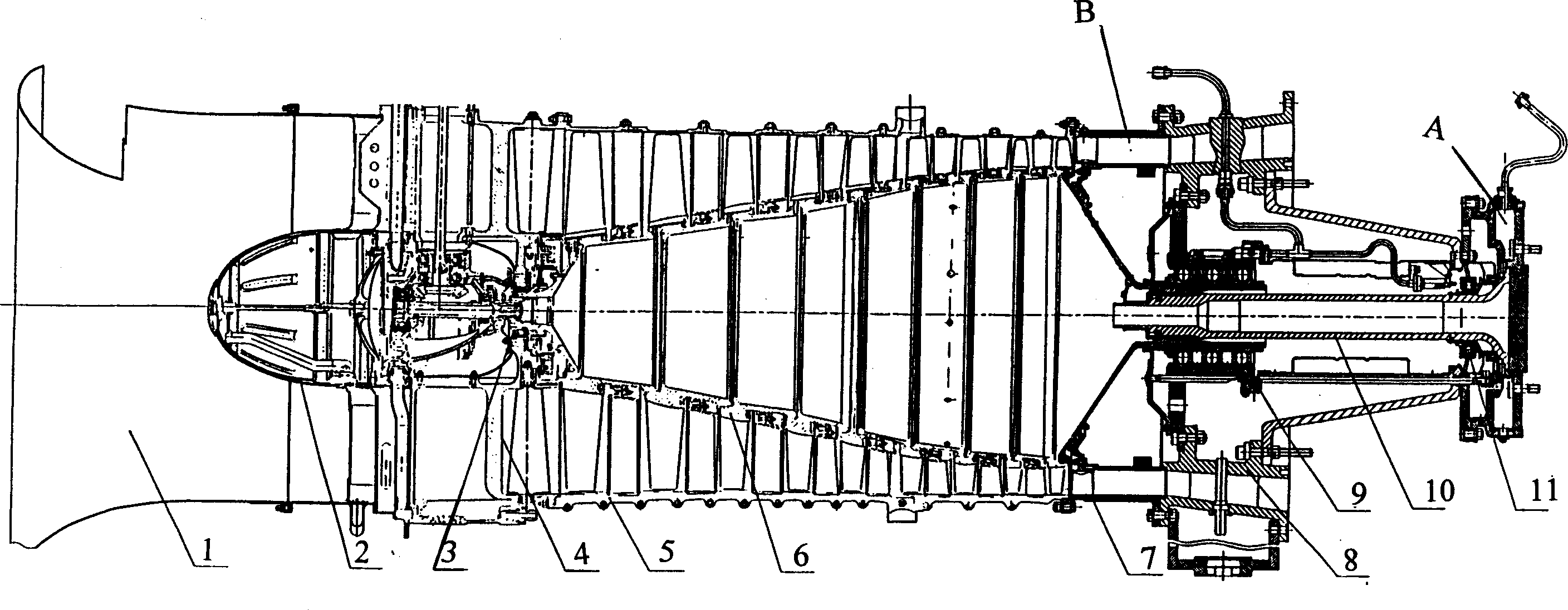

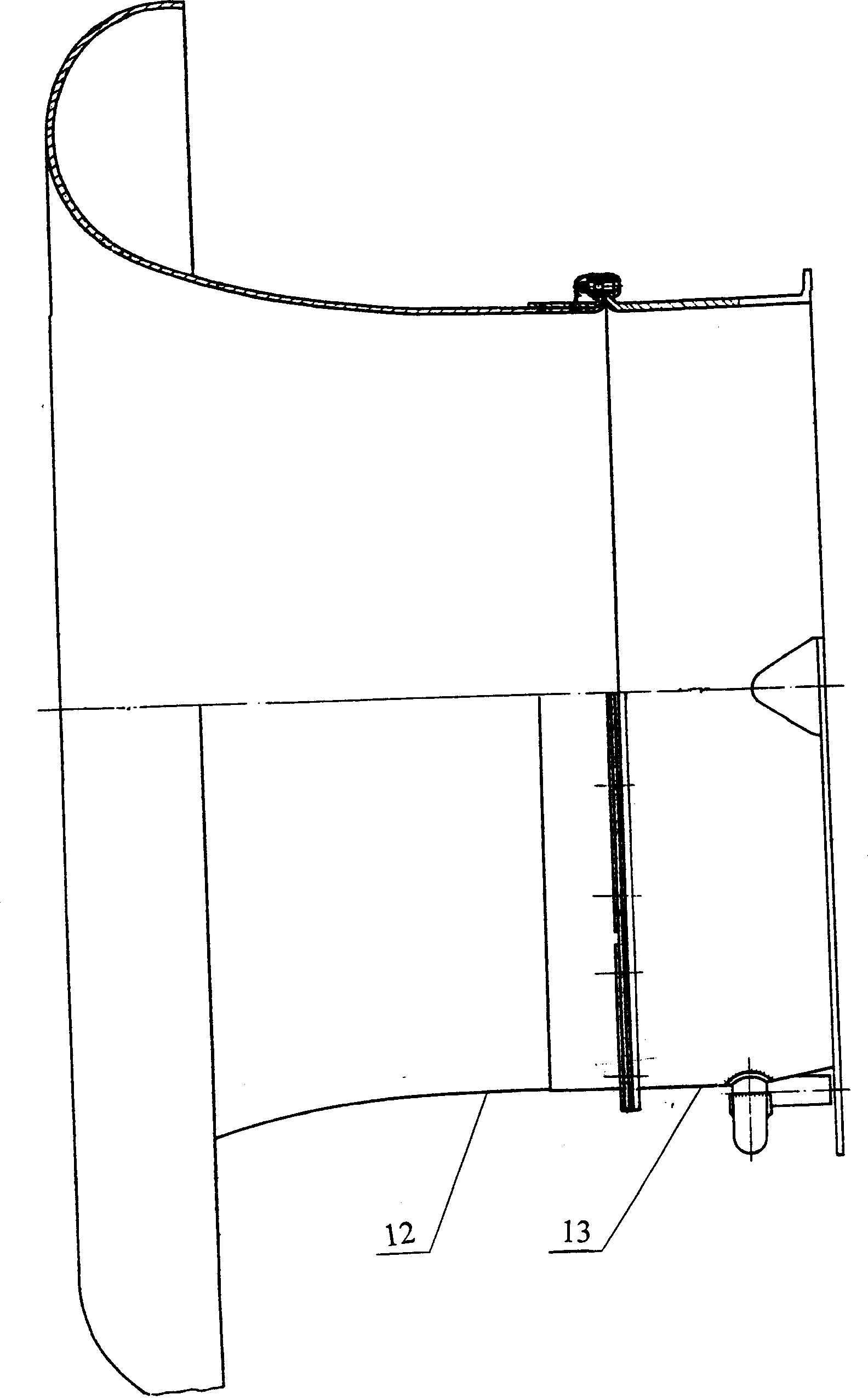

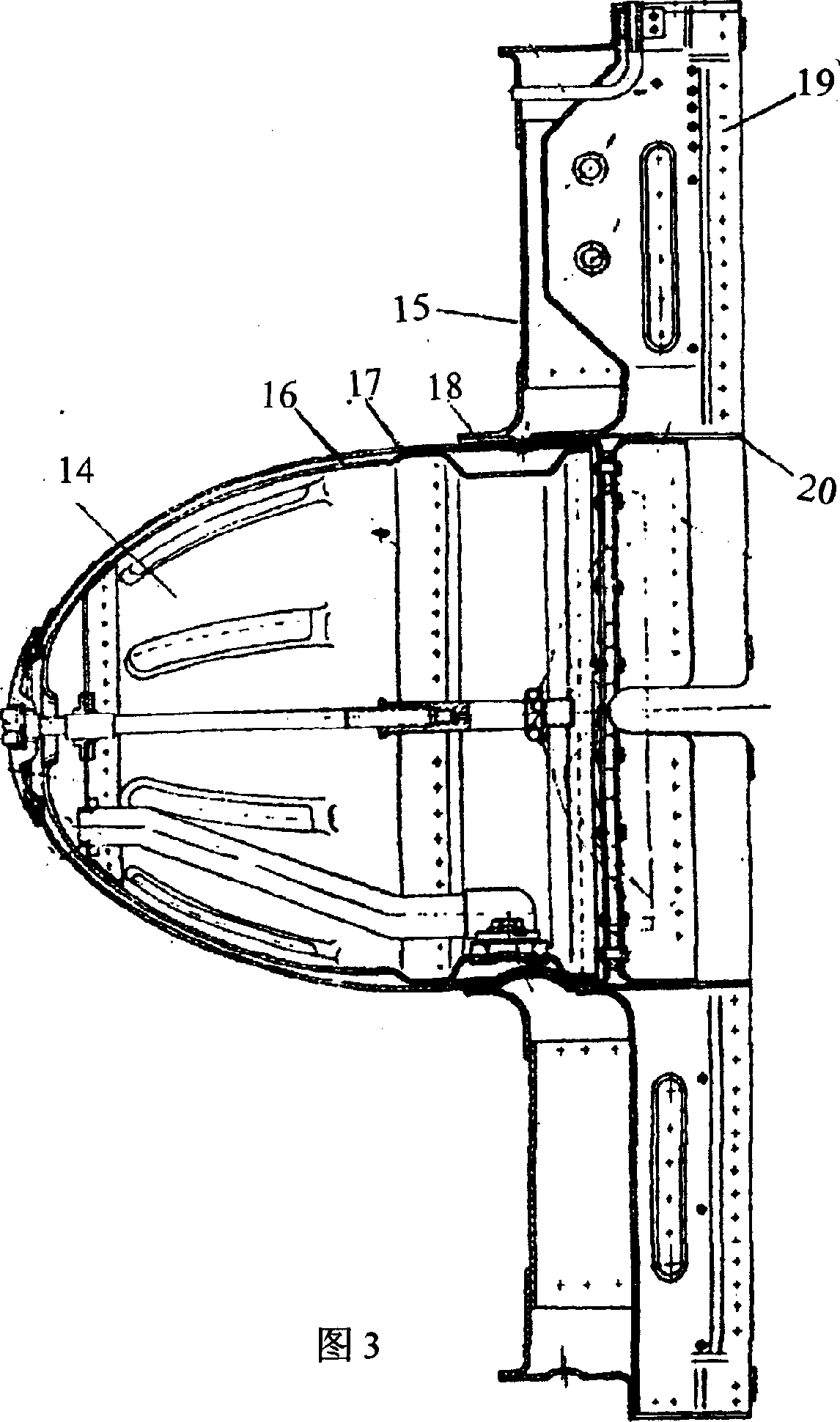

[0024] like figure 1 As shown, the axial flow fan of the present invention is composed of an air inlet assembly 1, an air intake device 2, a front support assembly 3, a front casing assembly 4, a middle casing assembly 5, a fan rotor assembly 6, a rear casing assembly 7, a rear bearing Force casing assembly 8, middle support assembly 9 (including middle support axial force bearing device), transmission shaft assembly 10, rear support assembly 11 (including rear support high pressure lead piece unloading device). The axial flow fan drive shaft assembly 10 is connected to the thrust plate 47 with the connecting bolts 58 (47, 58) through the thrust plate 47 fixed to it. Figure 9 Middle) is connected with the main shaft of the gas turbine through the coupling (not shown in the figure), the gas turbine drives the fan rotor assembly 6 to rotate at a high speed, the air enters the fan from the air inlet assembly 1, and the guide vanes on the air intake device 2 connect the rotor inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com