Molecular gel electrolyte and its prepn

A molecular gel and electrolyte technology, applied in circuits, electrical components, secondary batteries, etc., can solve problems such as performance degradation, plasticization system is not a stable system, increase battery interface impedance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

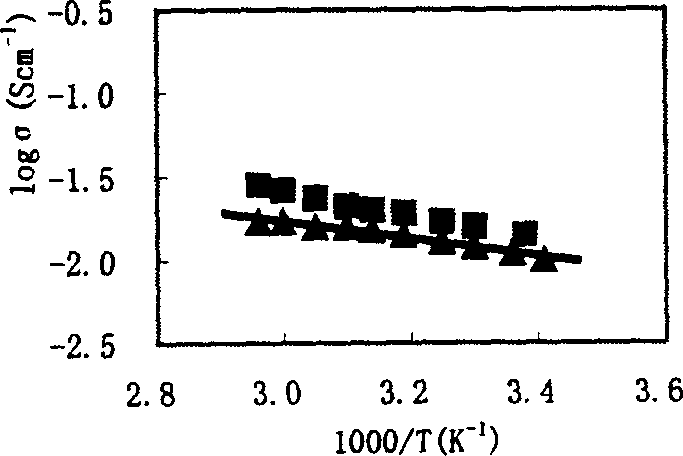

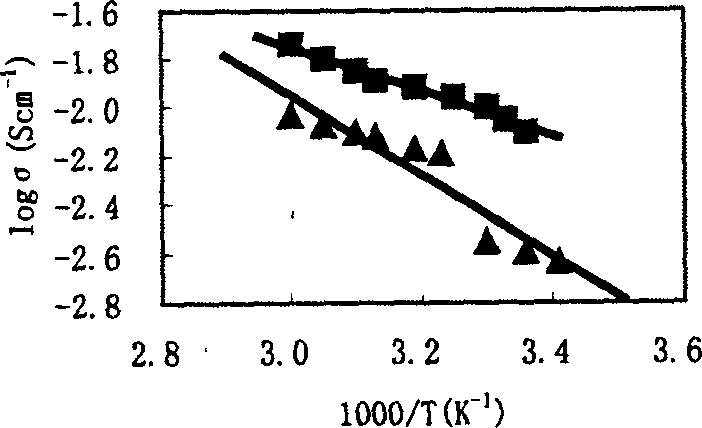

[0060] Lithium perchlorate (LiClO 4 ) aqueous solution, the concentration of lithium perchlorate is 0.15mol. Take 4.06 g of the lithium perchlorate aqueous solution and add 0.126 g of gel factor D to make the content of gel factor D in the solution 0.04 mol. The mixture was kept stirring at 65-80°C until all the solids were dissolved. The product is cooled to room temperature, and the inorganic lithium salt-containing molecular gel electrolyte is obtained.

[0061] Similarly, the preparation of lithium bis(trifluoromethylsulfonimide) (LiN(CF 3 SO 2 ) aqueous solution, the concentration of two (trifluoromethylsulfonimide) lithium is 0.15mol. After adding the gel factor D, the organic lithium salt-containing molecular gel electrolyte is obtained. The room temperature conductivity of two different lithium salt salt molecular gel electrolytes is at 10 -1 ~10 -2 S cm -1 between.

Embodiment 2

[0063] Lithium perchlorate (LiClO 4 ) of propylene carbonate (PC) solution, the concentration of lithium perchlorate is 0.15mol. Take this lithium perchlorate propylene carbonate solution 4.06g, add 0.126g gel factor D, make the content of gel factor D in the solution be 0.04mol. The mixture was kept stirring at 80-100°C until all solids were dissolved. The product is cooled to room temperature to obtain a molecular gel electrolyte containing inorganic lithium salt propylene carbonate.

[0064] Similarly, the preparation of lithium bis(trifluoromethylsulfonimide) (LiN(CF 3 SO 2 ) of propylene carbonate solution, the concentration of two (trifluoromethylsulfonimide) lithium is 0.15mol. After adding the gel factor D, the molecular gel electrolyte containing organic lithium salt propylene carbonate is obtained. The room temperature conductivity of two different lithium salt organic molecular gel electrolytes is at 10 -3 S cm -1 between.

Embodiment 3

[0066] Similar to the methods of Examples 1 and 2, dimethylformamide (DMF) molecular gel electrolytes containing lithium perchlorate and lithium bis(trifluoromethylsulfonimide) were respectively prepared.

[0067] Similar to the methods of Examples 1 and 2, dimethyl sulfoxide (DMSO) molecular gel electrolytes containing lithium perchlorate and lithium bis(trifluoromethylsulfonimide) were prepared respectively.

[0068] The room temperature conductivity of DMF or DMSO organic molecular gel electrolyte is 10 -3 ~10 -4 S cm -1 between.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity at room temperature | aaaaa | aaaaa |

| Conductivity at room temperature | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com