One-dimensional cadmium sulfide nanorod catalyst, and preparation method and application thereof

A technology of cadmium sulfide nanorods and catalysts, which is applied in the direction of physical/chemical process catalysts, cadmium sulfide, nanotechnology, etc., can solve the problem of limited material selection range, sound-driven hydrogen production efficiency needs to be improved, and can not meet the requirements of sound energy-hydrogen energy Convert technology development needs and other issues to achieve the effect of simple operation and few steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

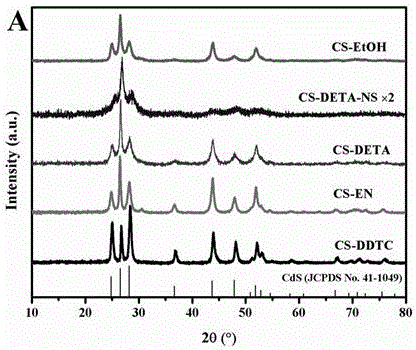

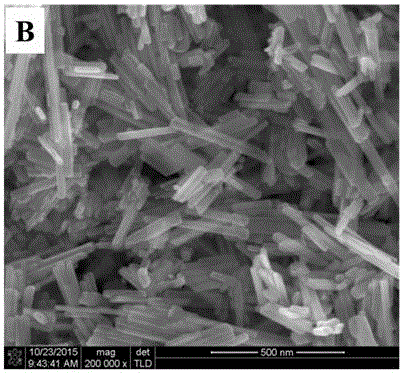

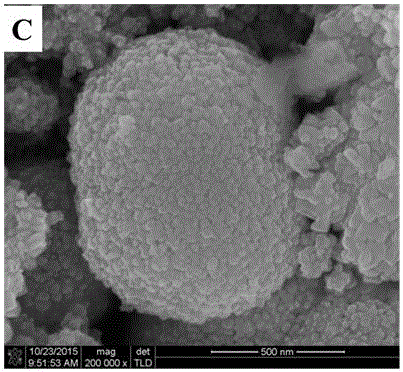

[0023] One-dimensional CdS nanorods prepared by one-step method

[0024] Weigh 0.3660 g of CdCl 2 (2 mmol) and 0.064 g of sulfur powder (2 mmol), placed in a polytetrafluoroethylene reactor with a volume of 100 mL, added 60 mL of diethylenetriamine (DETA), stirred for 30 min to make the precursor uniform After mixing, the reaction kettle was covered and sealed, put into a stainless steel sleeve and locked, placed in a temperature-programmed blast oven, and raised from room temperature to 160°C over 30 minutes, and then naturally dropped to room temperature after 24 hours of heat preservation; the obtained precipitation was used for Wash 4 times with deionized water until the ion concentration of the mother liquor drops below 20ppm, then wash once with absolute ethanol, transfer to a vacuum oven at 60°C and dry for 12 h to obtain a yellow powder, which is labeled as CS-DETA sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com