A kind of ultra-hydrophobic filter net and preparation method thereof

A filter screen and super-hydrophobic technology, applied in the field of nanomaterials, can solve the problems of unsatisfactory use requirements, high temperature resistance, corrosion resistance and super-hydrophobic performance are not ideal, and achieve reduced energy consumption and production costs, excellent super-hydrophobic performance, A wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation process of superhydrophobic filter net is:

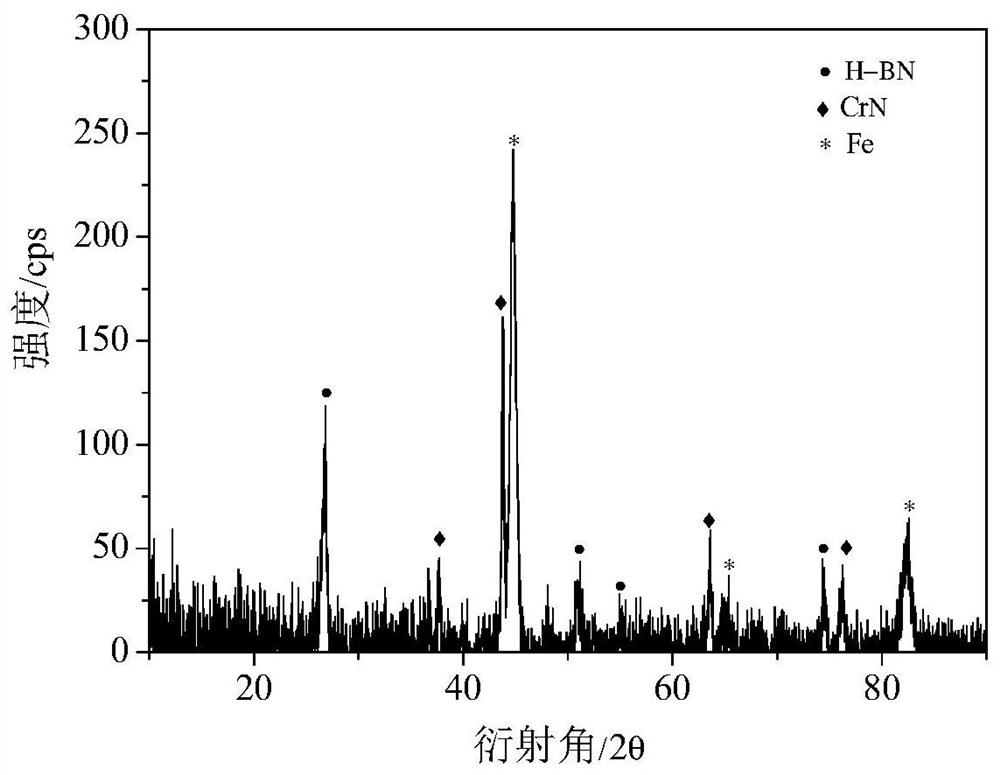

[0040] (1) Mix boron oxide and magnesium powder at a molar ratio of 1:1.5 to 1:2.5, and ball mill in a planetary ball mill for more than 0.5 hours under the protection of nitrogen to obtain a solid powder with a particle size of 2 to 10 microns, boron nitride The molecular formula is BN.

[0041] (2) Place the solid powder obtained in step (1) in a square porcelain boat, place a 30mm×30mm metal mesh at the center of the top of the porcelain boat, and place the porcelain boat in a tubular atmosphere protection annealing furnace. Put an inert protective atmosphere into the furnace tube of the tubular atmosphere protection annealing furnace, start heating from normal temperature under the protection of 20-200ml / min inert protective atmosphere, the heating rate is 5-80°C / min, and the temperature rises to 300-500°C Close the inert protective atmosphere valve at the same time, pass high-purity ammonia gas into the ...

Embodiment 1

[0044] (1) Boron oxide and metal magnesium powder are mixed according to the molar ratio of 1:2, placed in a ball mill tank, and under the protection of nitrogen, adopt the mode of forward and reverse alternating operation, and ball mill for 4 hours to obtain a uniformly mixed solid powder, granular The diameter is about 2 to 10 microns.

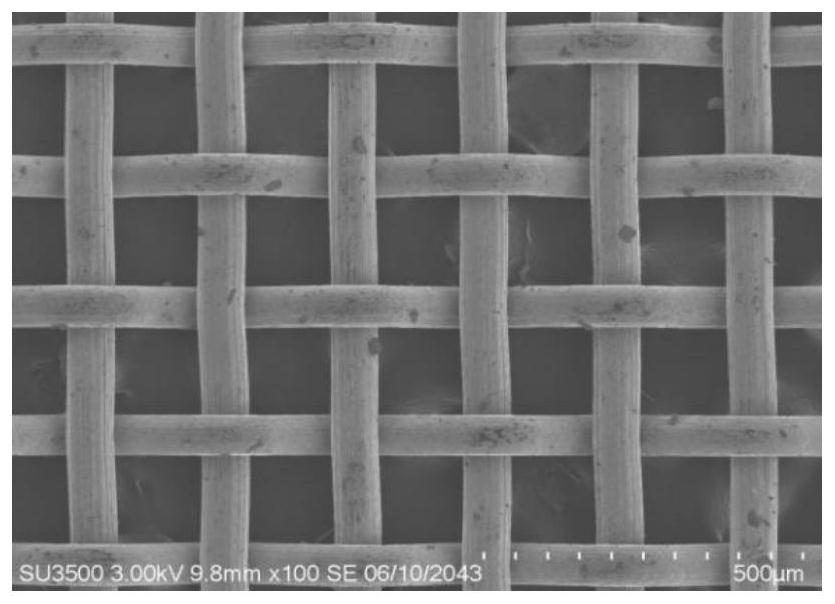

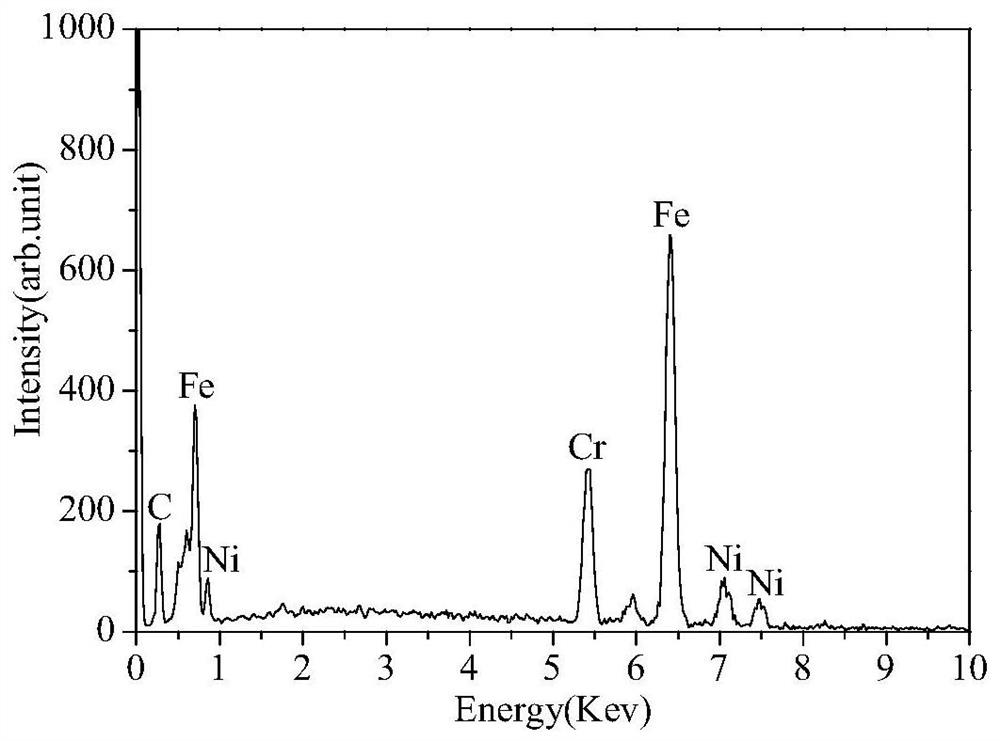

[0045] (2) Place the solid powder obtained in step (1) in a square porcelain boat of 60mm×30mm, place a piece of metal mesh of 30mm×30mm on the porcelain boat, and make it in the middle position, at 20ml / min Under the protection of argon, start to heat up from normal temperature, and the heating rate is 10°C / min. When the temperature rises to 300°C, close the argon valve, feed high-purity ammonia gas, with a flow rate of 150ml / min, continue to heat up to 1225°C, and keep warm for 8 hours. , and then stop feeding high-purity ammonia gas, then naturally cool down to room temperature under an inert protective atmosphere, and deposit a white sub...

Embodiment 2

[0052] Change the reaction temperature of step (2) in Example 1 to 1250° C., and other operations are the same as in Example 1, and the product obtained is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com