Process for decalcifying and extracting collagen from turtle carapace by utilizing ultrasonic assistance

A collagen and ultrasound-assisted technology, applied in the field of decalcification and extraction of collagen, can solve the problems of low decalcification efficiency, pollution, and increased collagen loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

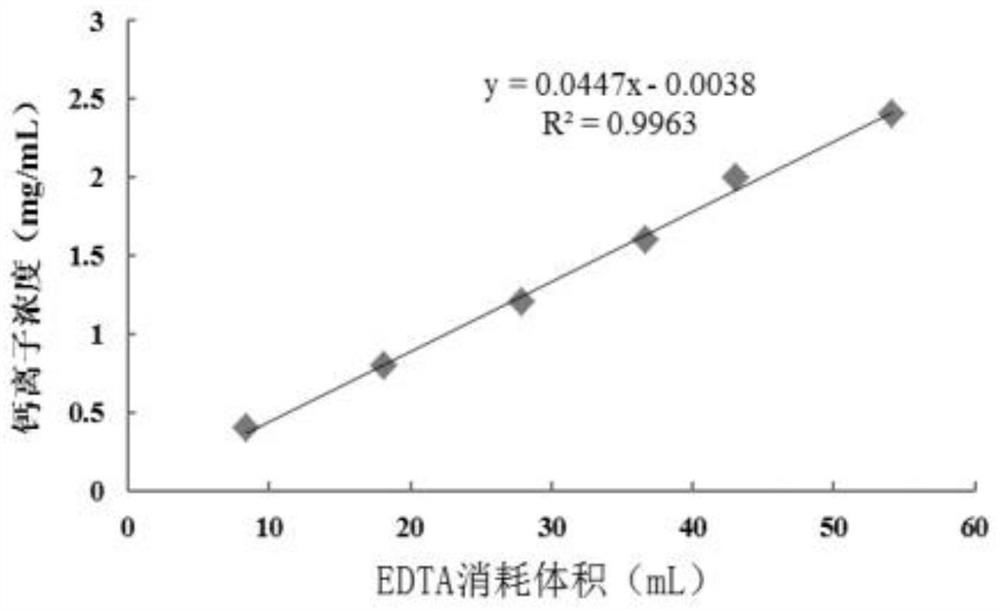

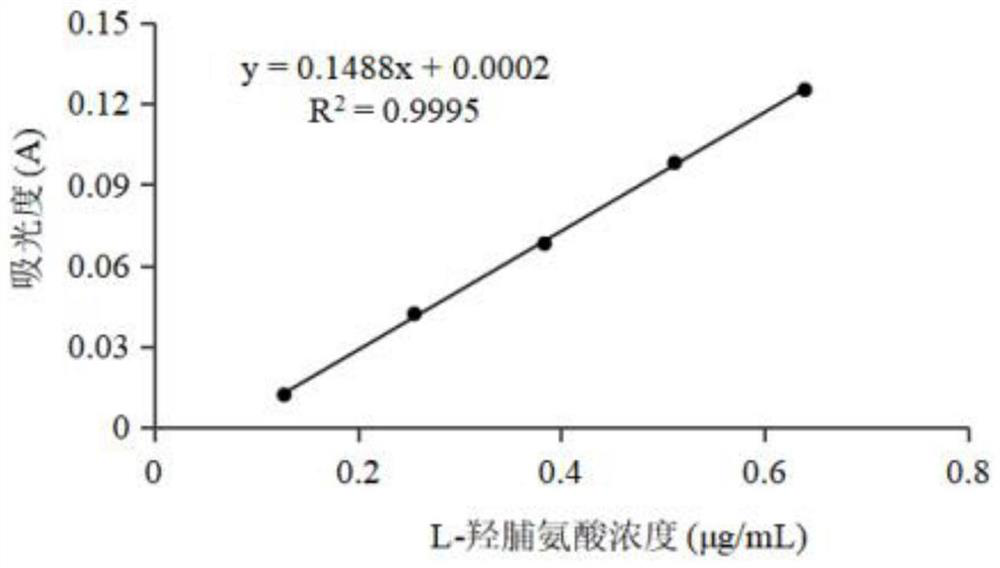

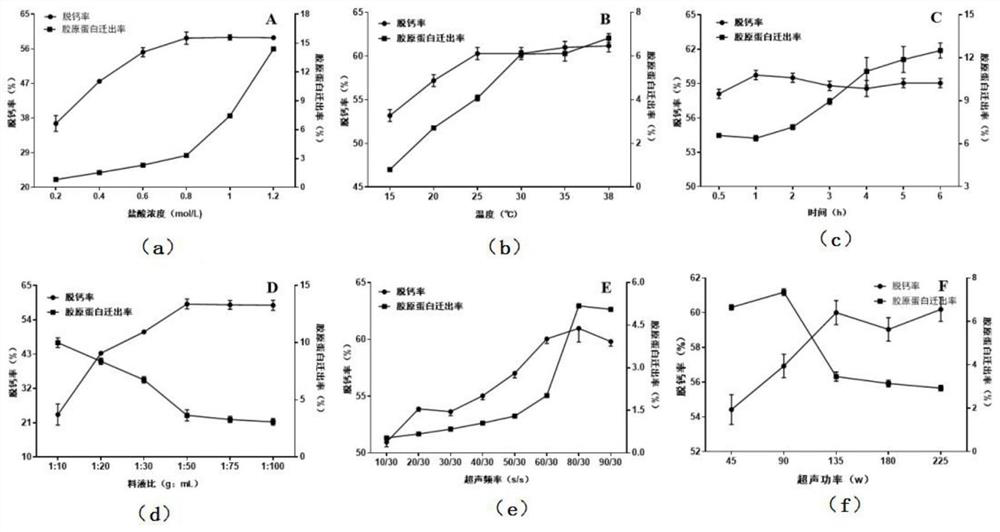

[0028] Embodiment 1: with reference to attached Figure 1-3 Shown is a process for extracting collagen from soft-shelled turtle carapace with the assistance of ultrasound, including steps:

[0029] 1. Preparation of materials and instruments

[0030] Carapace of soft-shelled soft-shelled turtle: purchased from a farm in Shaoxing, Zhejiang Province, and slaughtered to obtain the carapace; calcium carbonate, hydrochloric acid, nitric acid, sodium citrate, disodium edetate, sodium hydroxide, anhydrous sodium acetate, etc. are all analytically pure ; ME204-electronic analytical balance: Mettler; S220-KpH meter: Mettler; ALPHA 2-4LD plus freeze dryer: Christ; Cary-100 UV spectrophotometer: Agilent; BPG-9140A precision drum Air drying oven: Shanghai Yiheng Company; JY92-ⅡN ultrasonic cell pulverizer: Ningbo Xinzhi Biotechnology Co., Ltd.;

[0031] 2. Method

[0032] Analysis of the basic components of soft-shelled soft-shelled turtle: crude protein content was determined by Kjeld...

Embodiment 2

[0057] Embodiment 2: see attached Figure 4-6 As shown, the physicochemical properties of collagen after decalcification of soft-shelled turtle carapace were analyzed

[0058] Take a 50g sample to decalcify according to the optimal decalcification process. After decalcification, the sample is freeze-dried; at the same time, a certain amount of freeze-dried powder is accurately weighed. , magnetic stirring speed 100rpm and other conditions to extract for 24 hours, centrifuge to get the supernatant, freeze-dry, obtain carapace collagen as a reference, and carry out the following research on physical and chemical properties:

[0059] (1) Ultraviolet scanning: the purified collagen sample is scanned by an ultraviolet scanner with a wavelength interval of 1 nm and a wavelength range of 190-800 nm. The obtained UV spectrum of the turtle carapace collagen at 190-800 nm is as follows Figure 4 Shown:

[0060] Its maximum absorption peak is located at 215nm, which is mainly related t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wave number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com