Chip transfer method and apparatus

A technology of predetermined positions and components, applied in the identification devices, instruments, semiconductor lasers, etc., can solve problems such as unavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

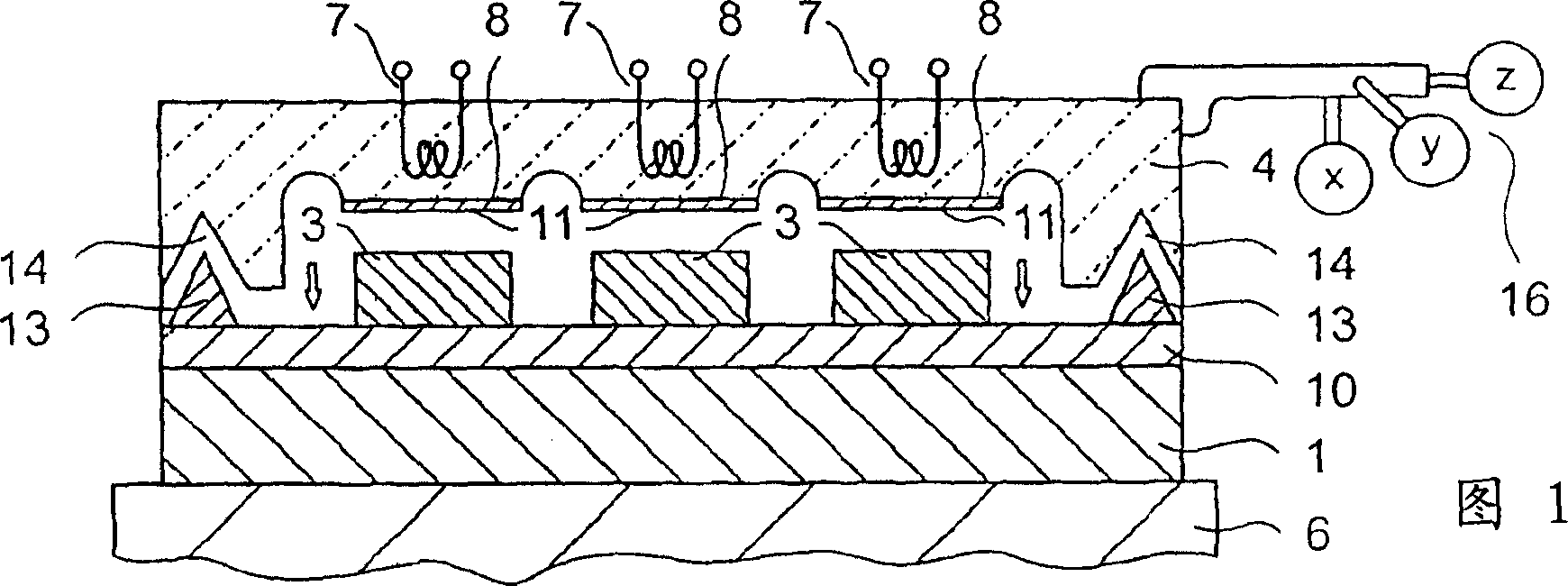

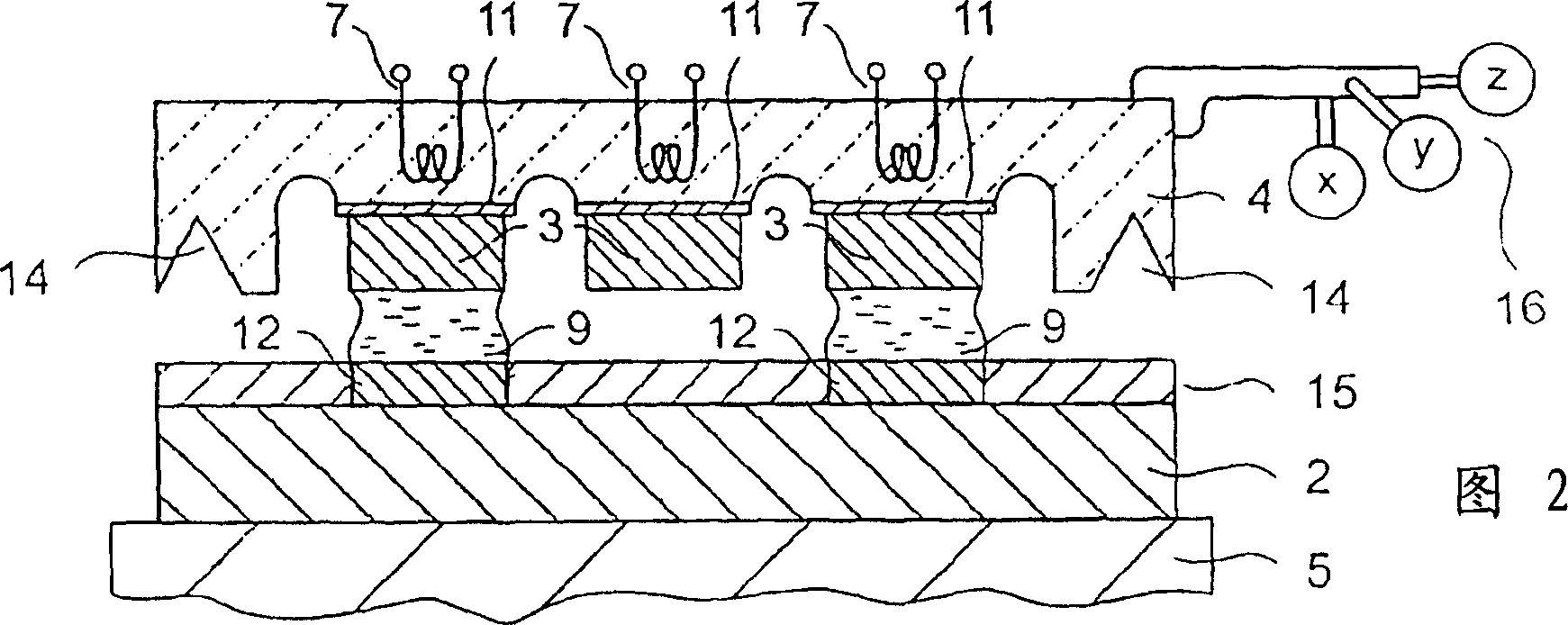

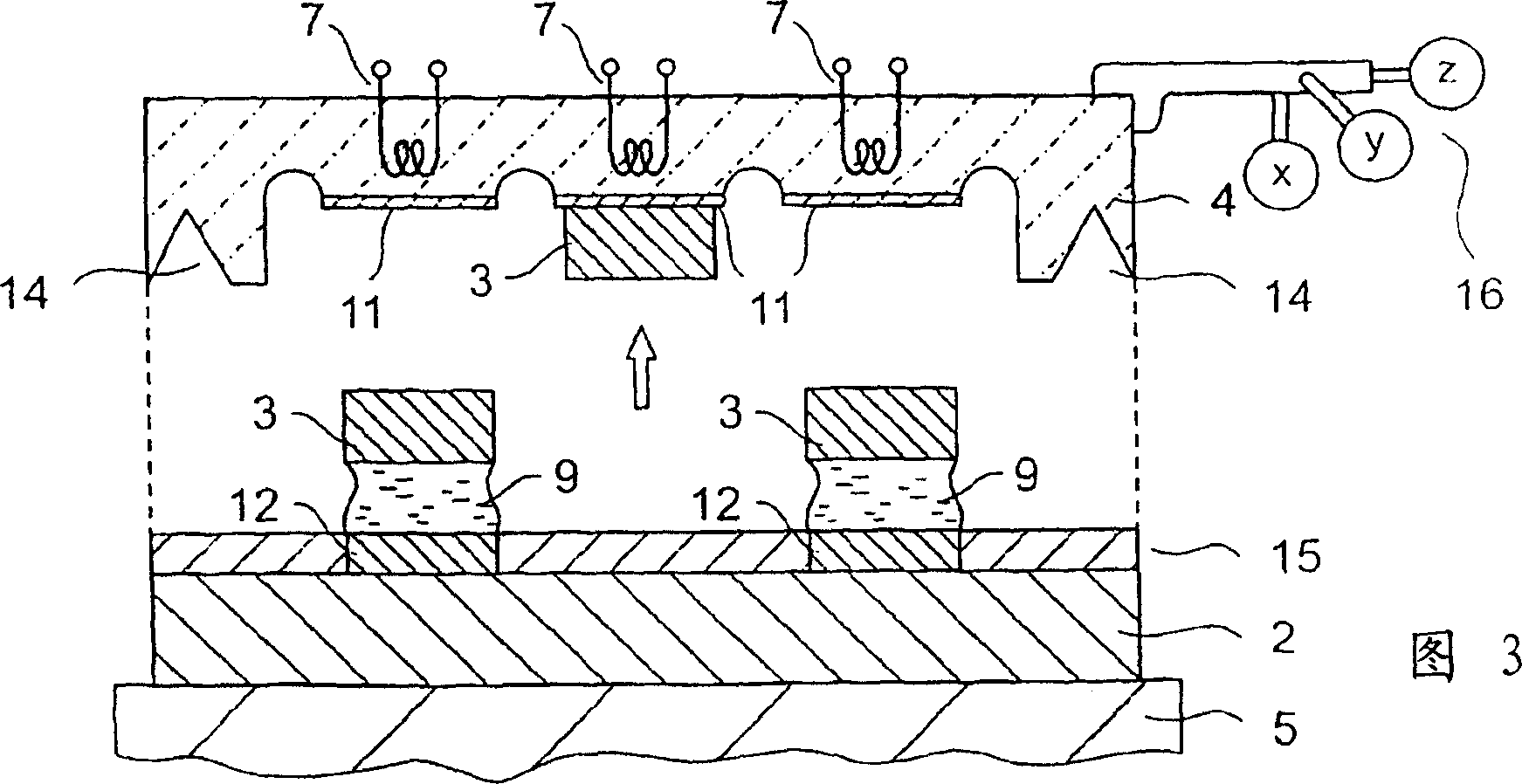

[0026] Next, various exemplary embodiments of the present invention are described.

[0027] As shown in FIG. 2, a CMOS wafer 2 containing several chips is processed by any existing CMOS process. Therein, the process is stopped after the last metallization step. The chip has landing areas 12 for integrated circuit elements 3 (here VCSELs 3 ). The landing area 12 is now the signal pad for the desired optical input. Then, the entire CMOS wafer 2 is made hydrophobic except for the landing area 12 . It is thus covered with a wettability-structure layer 15 configured such that the landing zone 12 is hydrophilic and the rest of the wettability-structure layer 15 is hydrophobic. The CMOS wafer 2 is also referred to as the target substrate 2 representing the VCSELs 3 of the integrated circuit components 3 . The landing area 12 is a predetermined location 12 for these integrated circuit components 3 . The CMOS wafer 2 is fixed on the target substrate mount 5 .

[0028]As depicted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com