Column shaped structure nano-silicon/non crystal silicon carbon composite photoconductive layer liquid crystal light valve and its preparation method

A technology of amorphous silicon carbon and columnar structure, applied in nonlinear optics, optics, instruments, etc., can solve the problems of slow response speed of light valves, low resolution, and serious lateral dispersion of carriers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

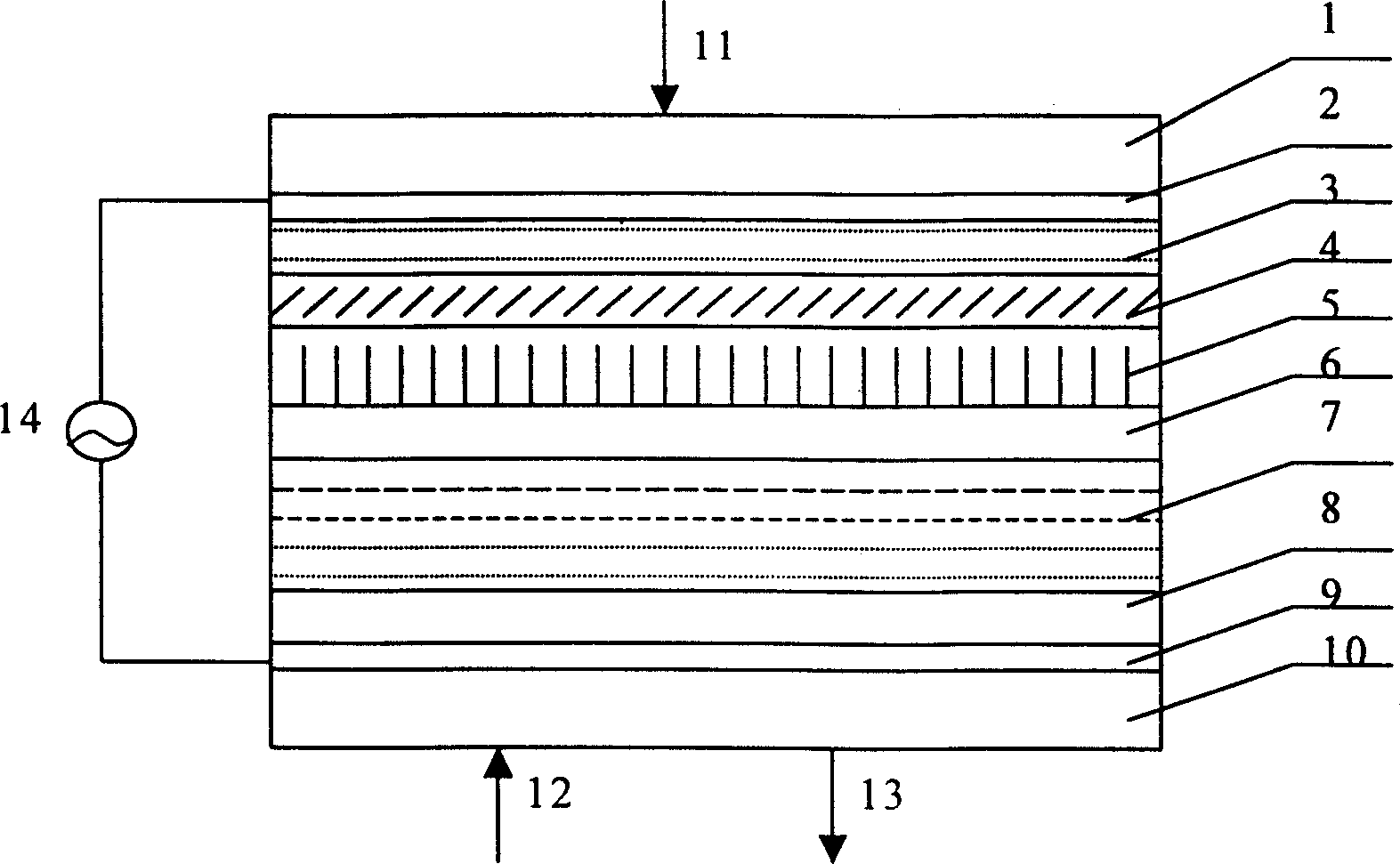

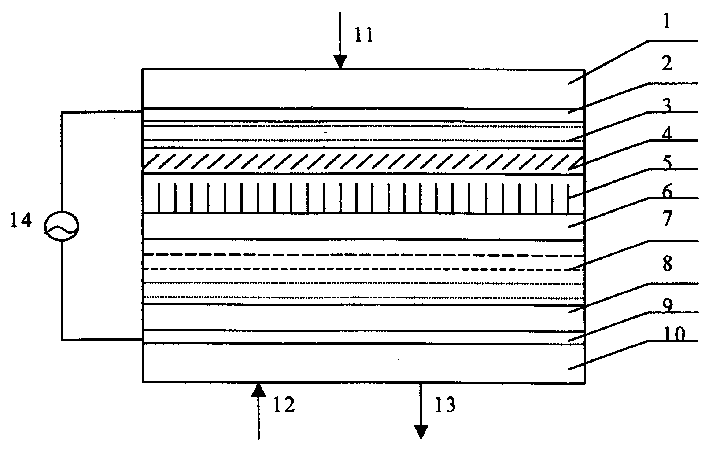

[0040] In the modified PECVD equipment, a layer of metal Al induction layer is deposited on the substrate coated with ITO film by vacuum thermal evaporation, the thickness is 20-350nm, the substrate temperature is 320°C, and the deposition vacuum is 7-9× 10 -3 Torr; then deposit a-SiC:H film on the Al layer by PECVD in the same reaction chamber, the deposition vacuum is 0.5-1Torr, the substrate temperature is 320°C, SiH 4 with H 2 The volume ratio is 4:1, SiH 4 with H 2 The flow rate of the mixed gas is about 400sccm, the radio frequency current is 100mA, and the frequency is 13.56MHz; 2 The annealing treatment is carried out for 1-6 hours under atmosphere, and the annealing temperature is 250-500°C. A columnar nc-Si / a-SiC:H photoconductive layer 3 with a light-to-dark conductivity ratio of 103 and a longitudinal conductivity 2 to 4 times that of the transverse conductivity is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com