Bulking machine for stalk

An extruder and straw technology, which is applied in the direction of feed, food science, application, etc., can solve the problems of stuffing, stuffy car, low processing efficiency, unreasonable structural design, etc., and achieve high processing efficiency, convenient assembly and maintenance, and absorption Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

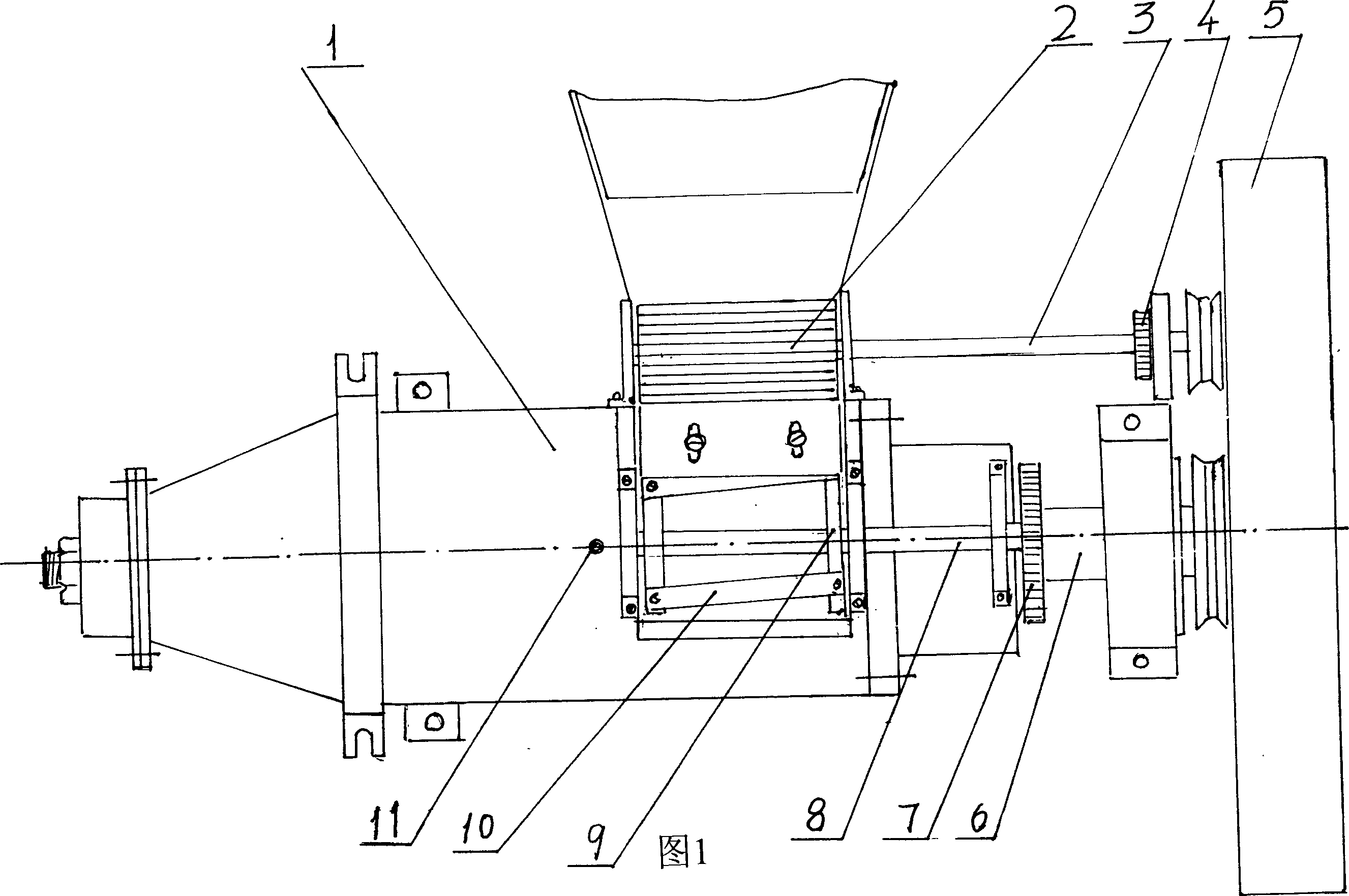

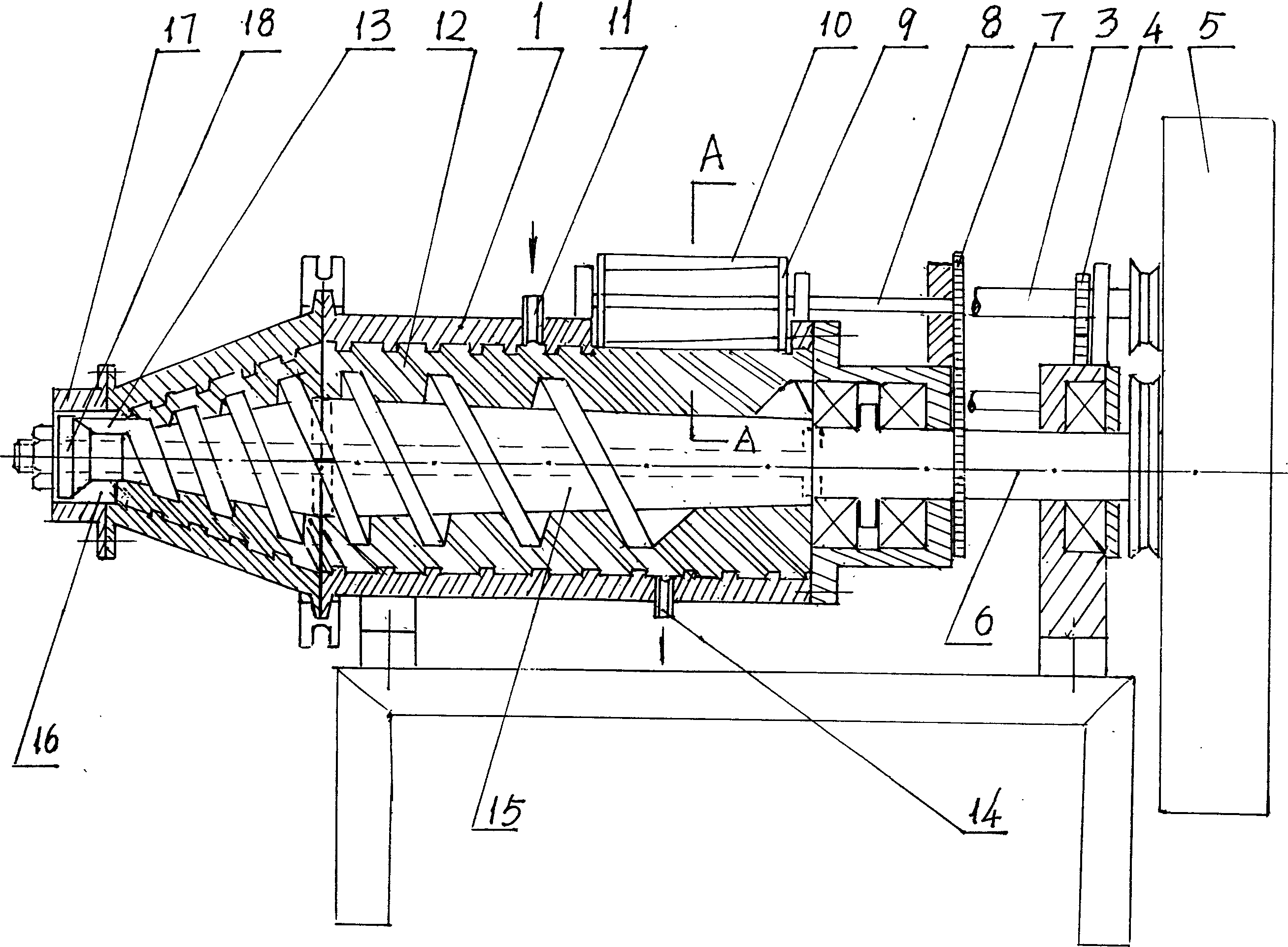

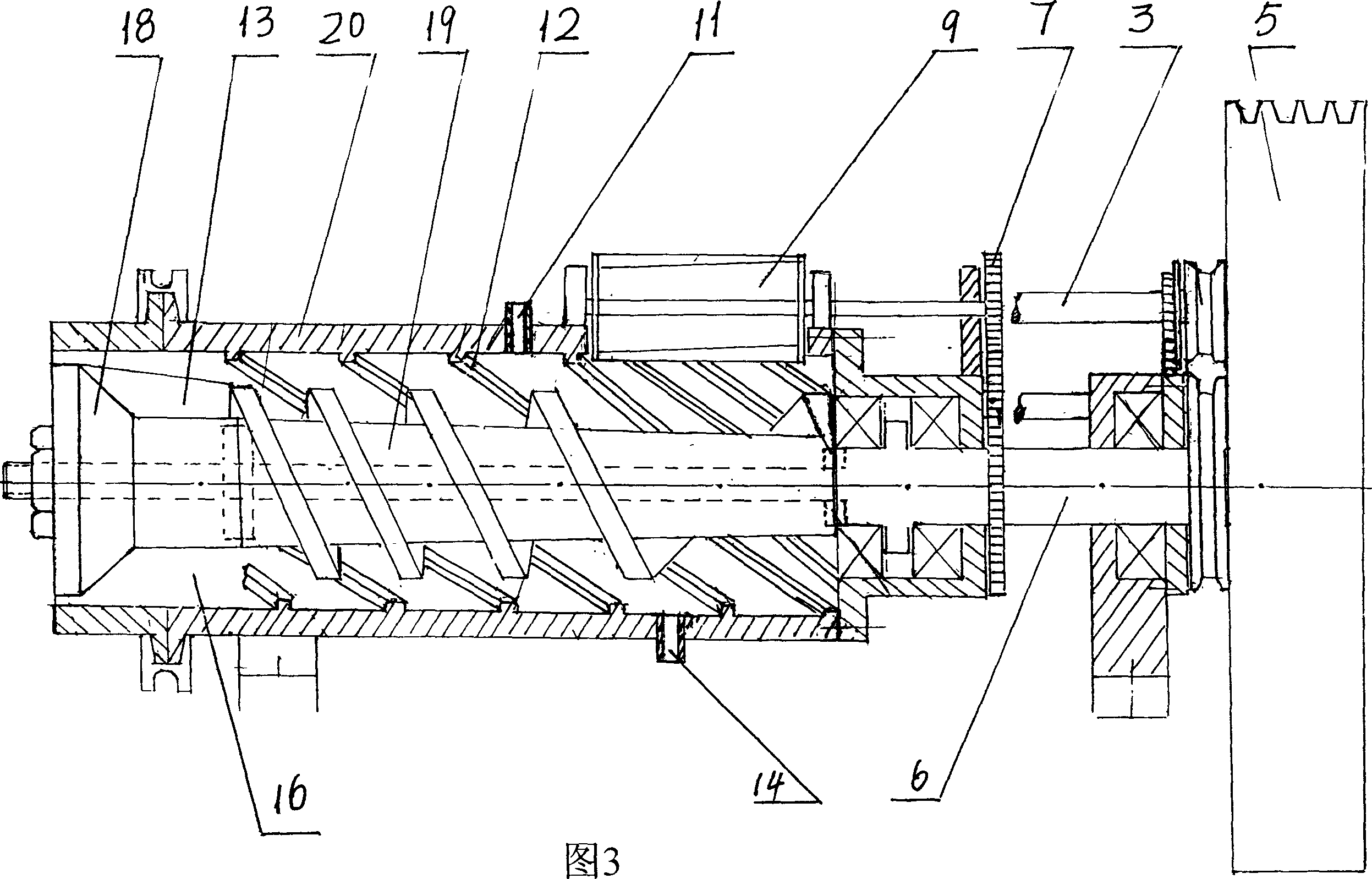

[0017] Embodiments of the present invention are described in detail in conjunction with the accompanying drawings. The shell 1 is formed by casting. It is assembled from the puffing nozzle 17 at the front end, the cone section and the main body. Spiral material guide strip 12, the spiral direction is compatible with the screw on the hinge dragon, the main shaft 6 passes through the bearing seat and extends into the housing 1, the hinge dragon 15 is connected with the main shaft 6 through a key and fixed with a nut, the front end of the hinge dragon 15 It is the puffing nozzle 18 matched with the puffing nozzle 17, on which, a side in the high-pressure vaporization chamber 16 is provided with a material pushing body 13, the main shaft 6 is connected to the power source through the belt pulley 5 at the end of the shaft, and the feeding and cutting mechanism is located at The upper side of the housing 1, which includes a hopper, a pair of feed rollers 2, a hob wheel 9 with a hob 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com