Polyester synthetic resin additive and plasticizer for biological degradability resin

A technology for synthetic resins and polyesters, applied in the field of additives for polyester synthetic resins and compositions of polyester synthetic resins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

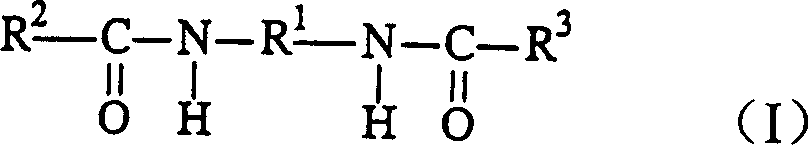

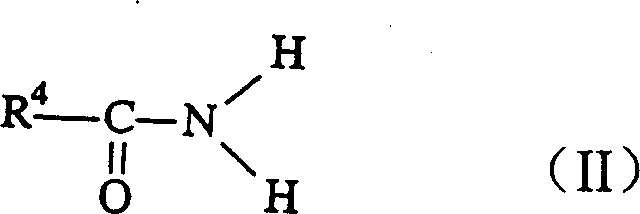

Method used

Image

Examples

Embodiment 1~12 and comparative example 1~4

[0189] 100 parts of amorphous polyester resin (Tsunami GS2: produced by イ-ストマンクミカル company, glass transition temperature 81 ° C, semi-crystallization time is infinite), 0.8 parts of linear sodium dodecylbenzenesulfonate, and as shown in Table 1 and Compositions comprising plasticizers and antiblocking agents having the types and amounts shown in Table 2 were kneaded for 15 minutes at 160° C. on a 6-inch rubber roll machine, and then the sliding properties were evaluated by the following method. In addition, this resin composition was made into the test piece of thickness 0.5mm at 190 degreeC with the press molding machine.

[0190] The softness, blocking resistance, and surface state of the prepared test pieces were evaluated by the following methods. The results are shown in Table 1 and Table 2.

[0191]

[0192] Punch the test piece into a No. 3 dumbbell shape, place it in a constant temperature room with a room temperature of 23° C. and a humidity of 50% for 24 hours, an...

Embodiment 13~18 and comparative example 5~6

[0221] 100 parts of amorphous polyester resin (Tsunami GS2: produced by イ-ストマンクミカル company, glass transition temperature 81 ° C, semi-crystallization time is infinite), 0.8 parts of linear sodium dodecylbenzenesulfonate, and as shown in Table 3 After kneading the composition of plasticizer and anti-blocking agent of the kind and amount shown at 160° C. for 15 minutes on a 6-inch rubber roll machine, the sliding property was evaluated by the following method. In addition, this resin composition was made into the test piece of thickness 0.5mm at 190 degreeC with the press molding machine.

[0222] The prepared test pieces were evaluated for transparency by the following method, and evaluated for flexibility and surface state by the above-mentioned method. Further, in order to evaluate its heat resistance, the test piece was placed in an oven controlled at 60°C for 4 hours, and after cooling at room temperature, the softness, transparency and surface state were similarly evaluate...

Embodiment 19~30 and comparative example 7

[0235] As a biodegradable resin, 100 parts of polylactic acid resin (such as produced by Mitsui Chemicals, Inc., trade name Leysia H-280) obtained after vacuum drying at 50° C. for 24 hours, and as shown in Table 3 and Table 4 The type and amount of plasticizer and anti-blocking agent formed composition were mixed for 15 minutes at 130°C on a 6-inch rubber roll machine, and were mixed in the same way as in Example 1 (but the roll temperature was changed to 130°C) Slidability was evaluated. In addition, this resin composition was made into the test piece of thickness 0.5mm at 190 degreeC with the press molding machine.

[0236] The softness of the prepared test piece was evaluated by the following method, and the blocking resistance and surface state were evaluated by the same method as in Example 1. The results are shown in Table 4 and Table 5.

[0237]

[0238] Punch the test piece into a No. 3 dumbbell shape, place it in a constant temperature room with a room temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com