Air flow system for microwave oven

A technology of air flow and microwave oven, which is applied in the direction of household stove/stove, household heating, lighting and heating equipment, etc. It can solve the problems of complex flow channels and increase product cost, so as to improve air flow velocity, save costs and achieve good cooling effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

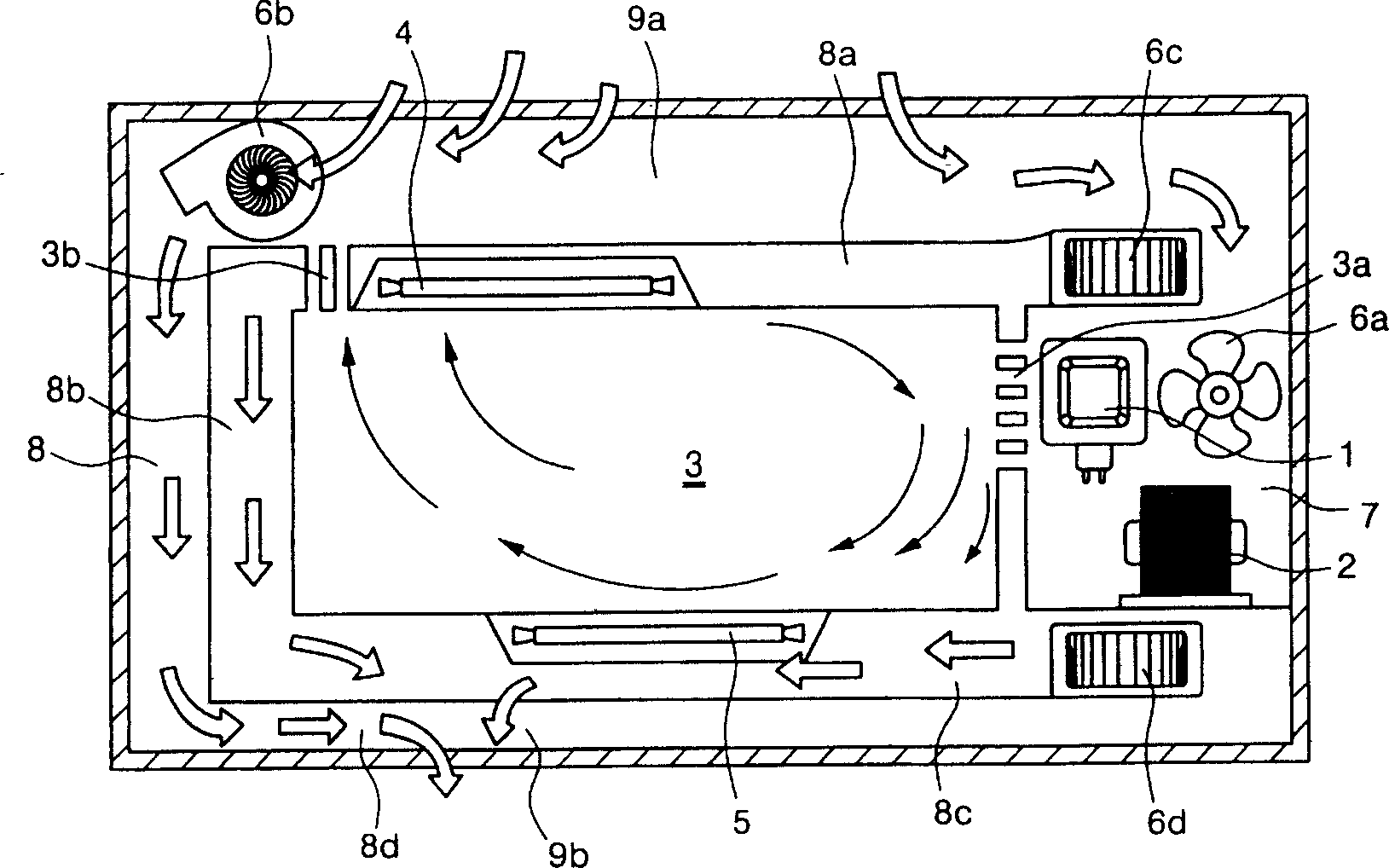

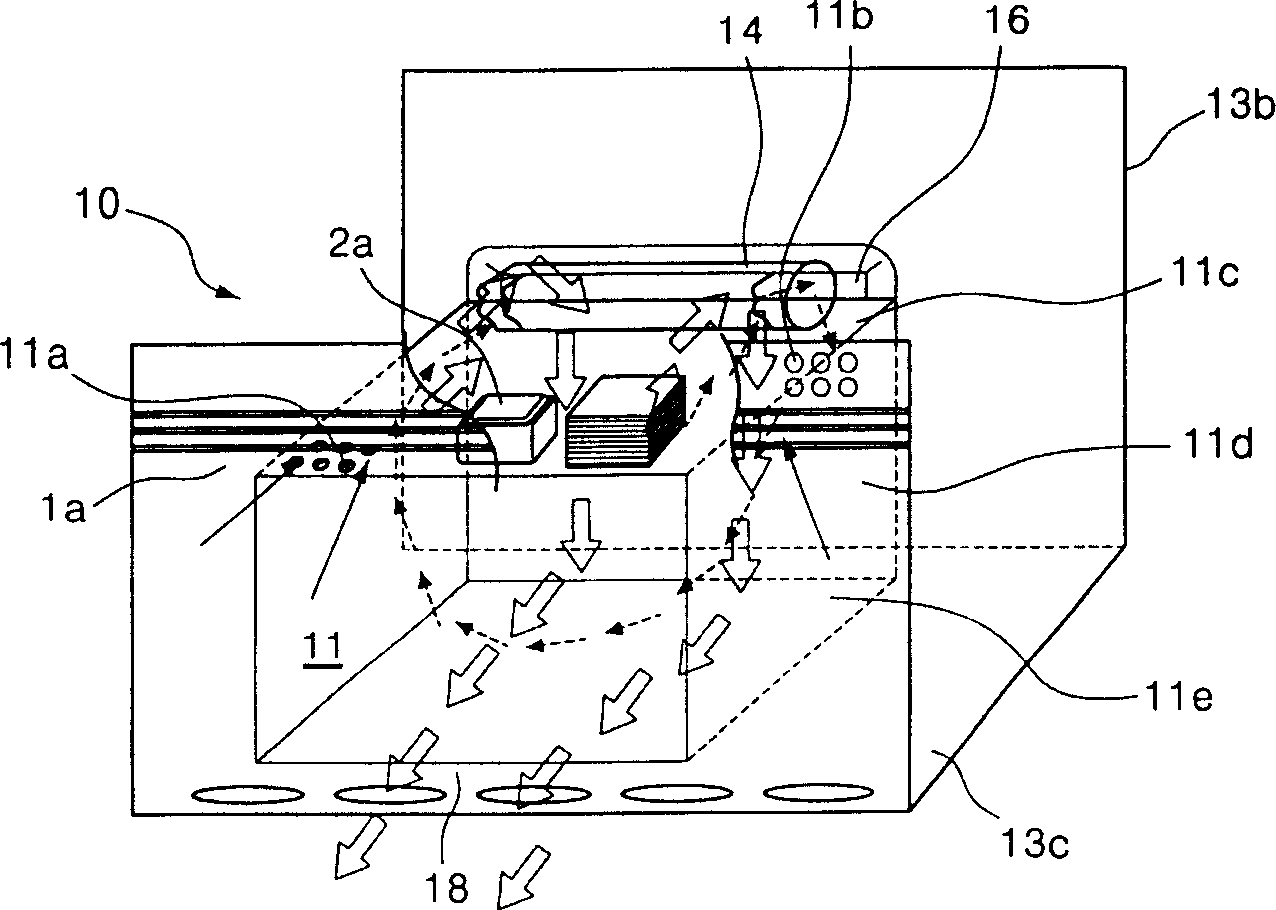

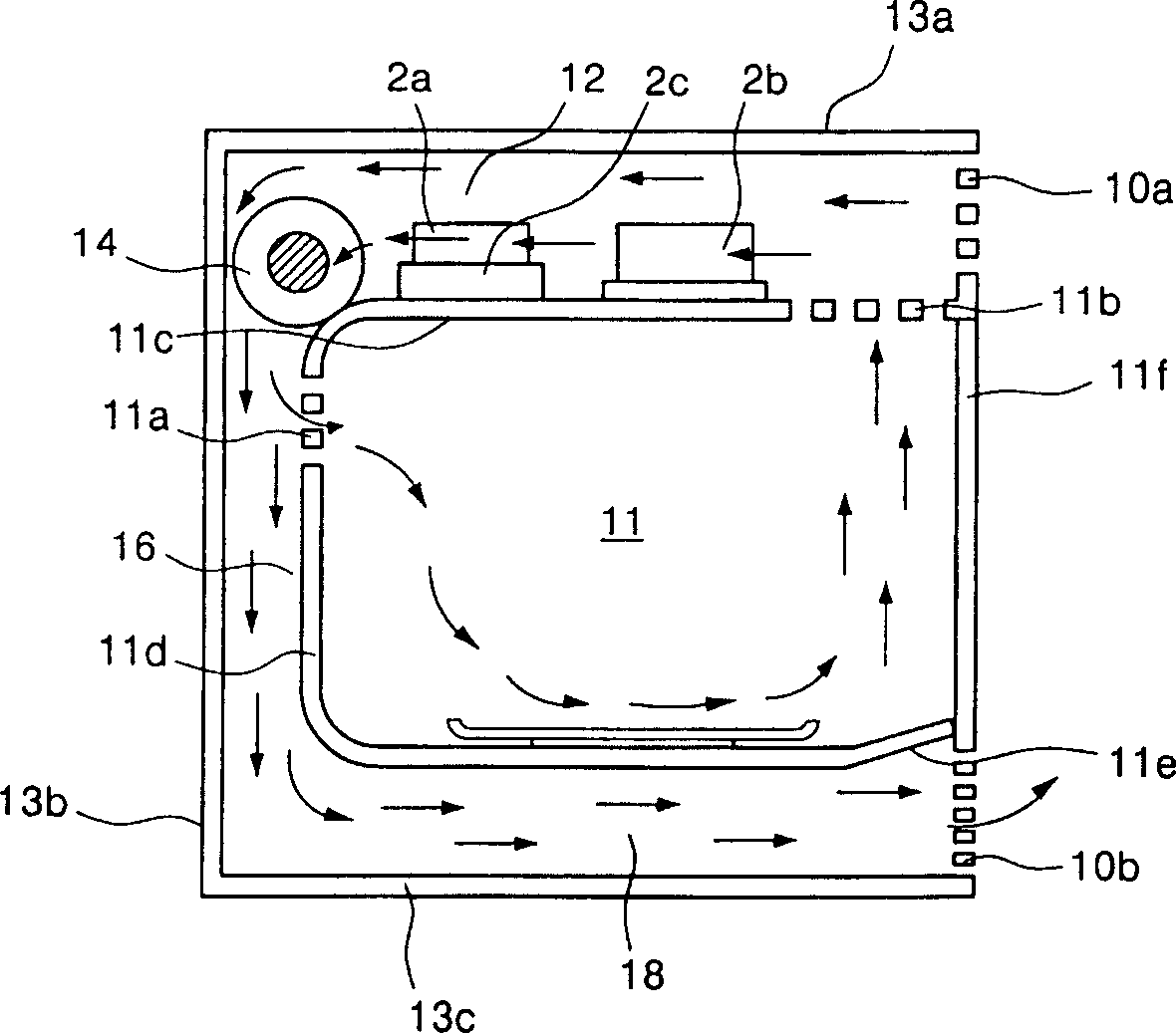

[0038] The structure of the embodiment of the air flow system of the microwave oven according to the present invention will be described in detail below with reference to the accompanying drawings.

[0039] figure 2 Shows the oblique view of the microwave oven of the present invention, image 3 A side view of a microwave oven of the present invention is shown.

[0040] figure 2 and image 3 In the shown embodiment, the electric control room 12 of the microwave oven is located between the upper surface 11c of the heating chamber of the microwave oven and the upper surface 13a of the outer casing. The electric control room 12 includes the following structures: a magnetron 2a, a high voltage transformer 2b and a waveguide 2c. The magnetron 2a generates microwaves; the high-voltage transformer 2b generates high-voltage current required for the magnetron 2a to generate microwaves; the waveguide 2c guides the microwaves generated by the magnetron 2a into the heating chamber. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com