Organic electroluminescent diode display element

A technology of electroluminescence and display components, which is applied in the direction of electrical components, electroluminescence light sources, electric light sources, etc., and can solve the problems of increased manufacturing process costs, film layer stress matching, and expensive investment in sputtering equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

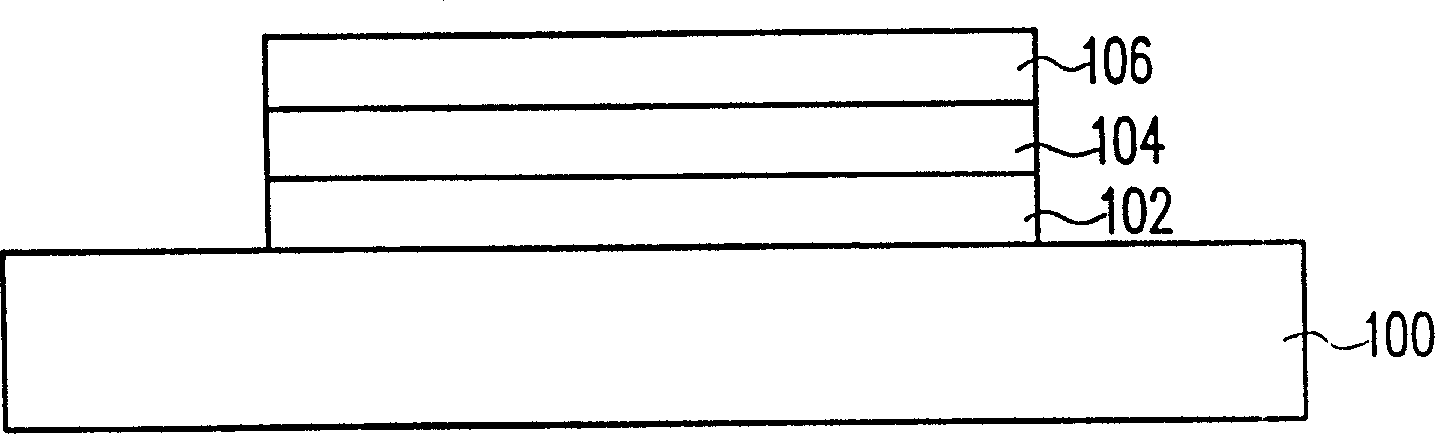

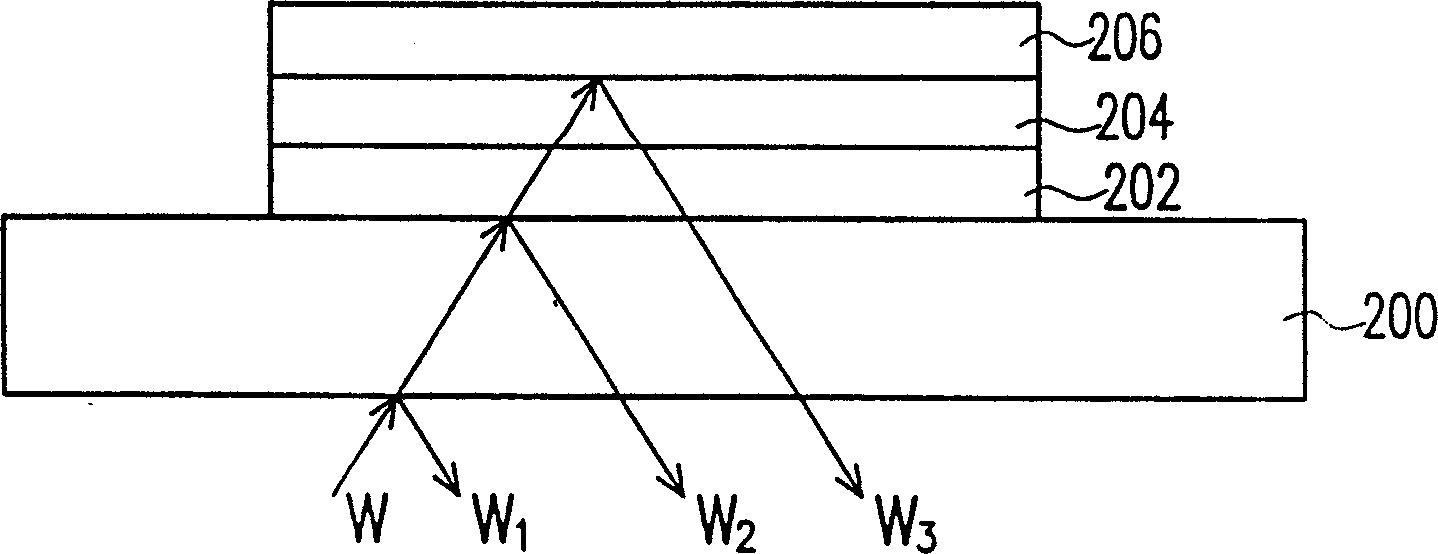

[0035] image 3 Shown is a schematic diagram of the reflection of external light in an organic electroluminescent diode display element. Please refer to image 3 The organic electroluminescent diode display element is mainly composed of a transparent substrate 200 , a plurality of strip-shaped transparent anodes 202 , an organic functional layer 204 and a plurality of strip-shaped metal cathodes 206 . Among them, the refractive index n of the organic functional layer 204 1 and the refractive index n of the transparent anode 202 2 very close, while the refractive index n of the organic functional layer 204 1 For example, greater than the refractive index n of the transparent substrate 200 3 , where n 1 About 1.7 or so, n 2 is approximately between 1.8 and 2.0, while n 3 is about 1.5, and n 3 Greater than the refractive index of outside air (≈1).

[0036] The light in the organic electroluminescent display element is generated by the organic functional layer 204 . Altho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com