Method and device for forming of glasses and/or glass ceramics

A technology for glass ceramics and glass, which is applied in the field of raw glass for processing glass ceramics, and can solve the problems of incompatibility, oxidation, adhesion to molds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

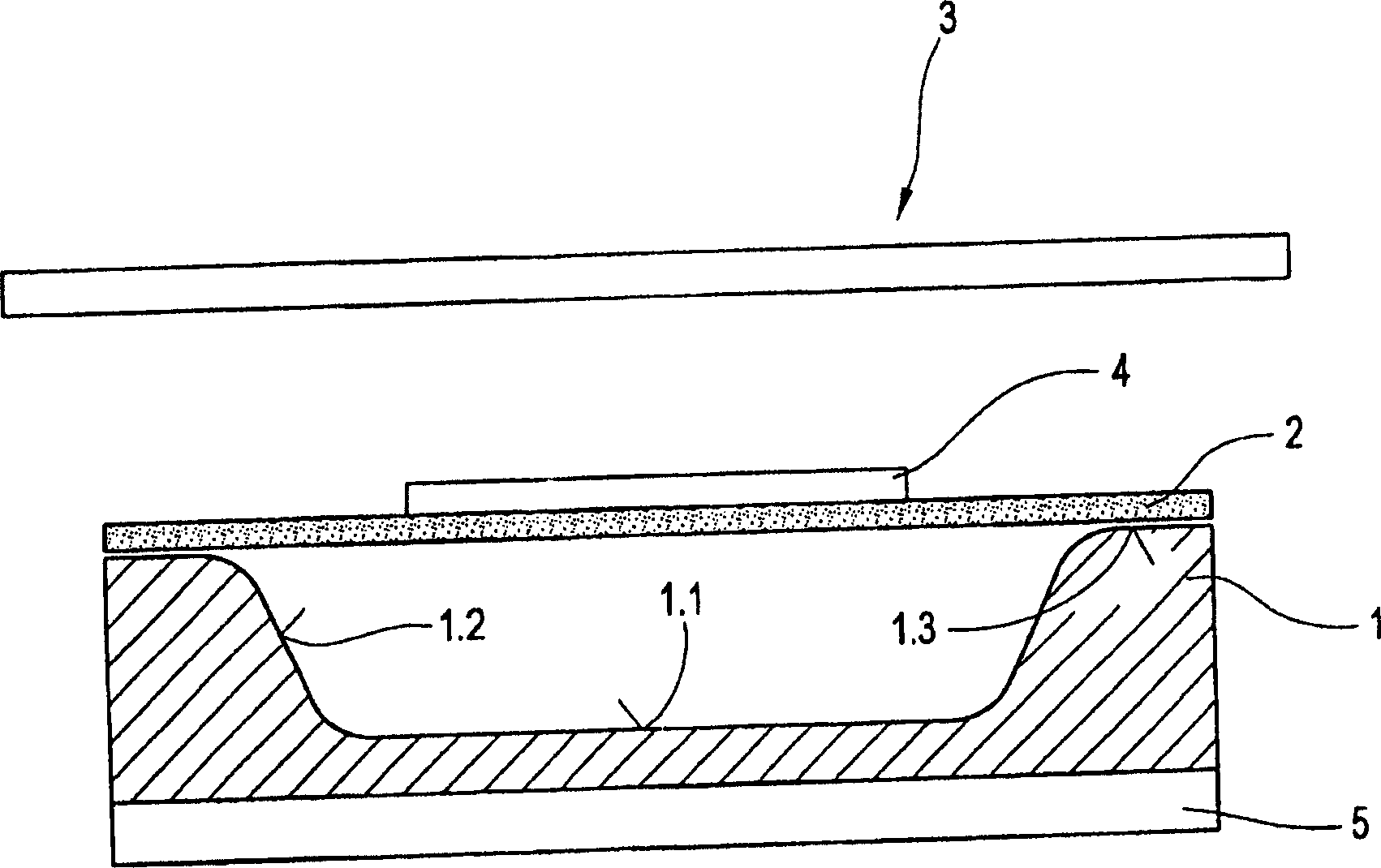

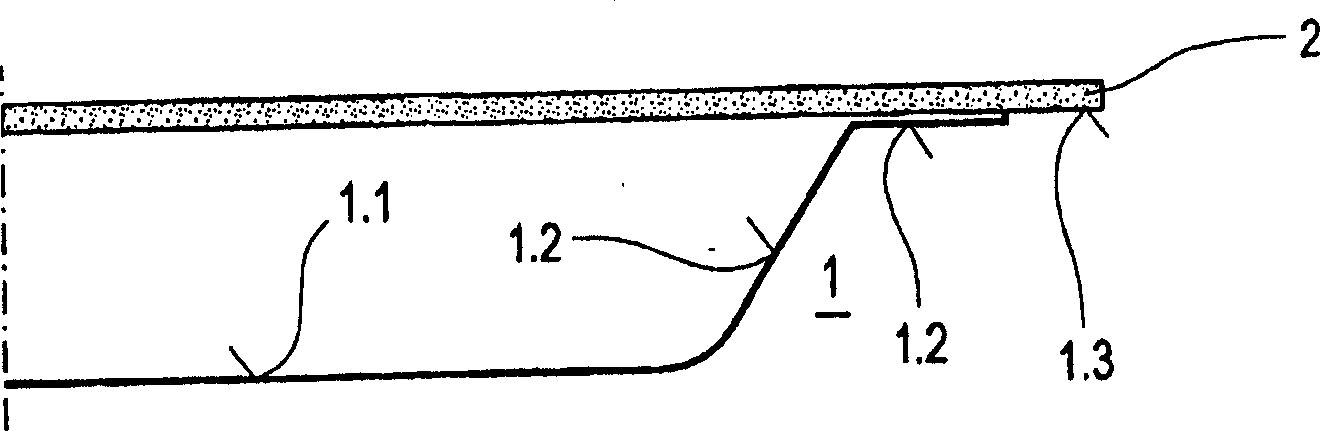

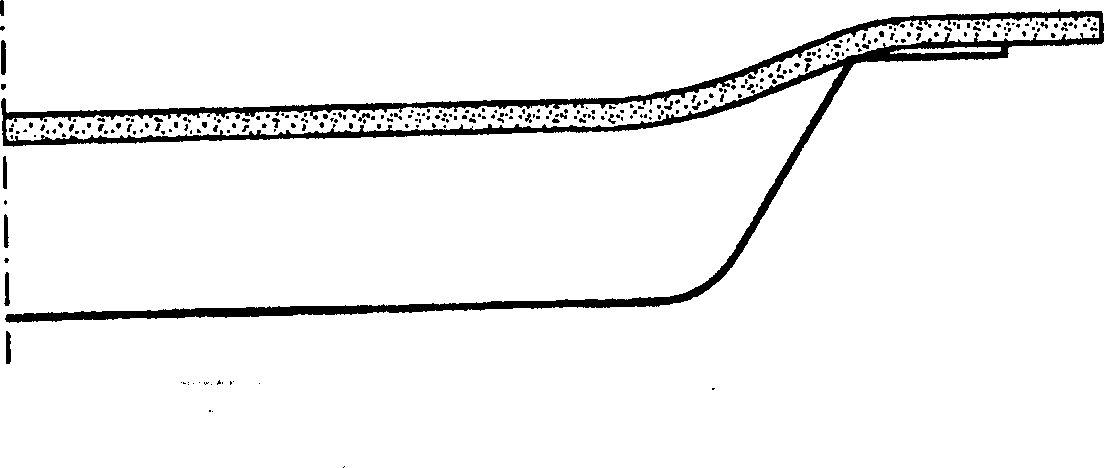

[0021] figure 1 A detail of a mold 1 for producing a baked shell is shown in . The mold 1 has a forming surface with a horizontally running bottom surface 1.1 in the present example, a side surface 1.2 and a support surface 1.3. The mold 1 in this example is made of metal with a reflectivity of 90% and a high thermal conductivity. The advantage of this is that the temperature distribution on the mold is uniform, which is beneficial to ensure the quality of the product to be manufactured.

[0022] A glass pane 2 is placed on the mold 1 , the glass pane 2 having exactly the same rectangular shape as the mold 1 in top view, the glass pane 2 resting with its peripheral region on the support surface 1 . 3 of the mold 1 .

[0023] Heater 3 is an important element, which includes a short-wave infrared radiation device with a color temperature of 2500K. The glass plate 2 has a thickness of 3.7 mm and a width of 250 mm, it is at a distance of 55 mm from the radiation emitter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com