Index tunable thin film interference coatings

A technology of thin film interference and refractive index, applied in thin material processing, optical waveguide coupling, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Various aspects of the invention and its applications are illustrated by the following several examples.

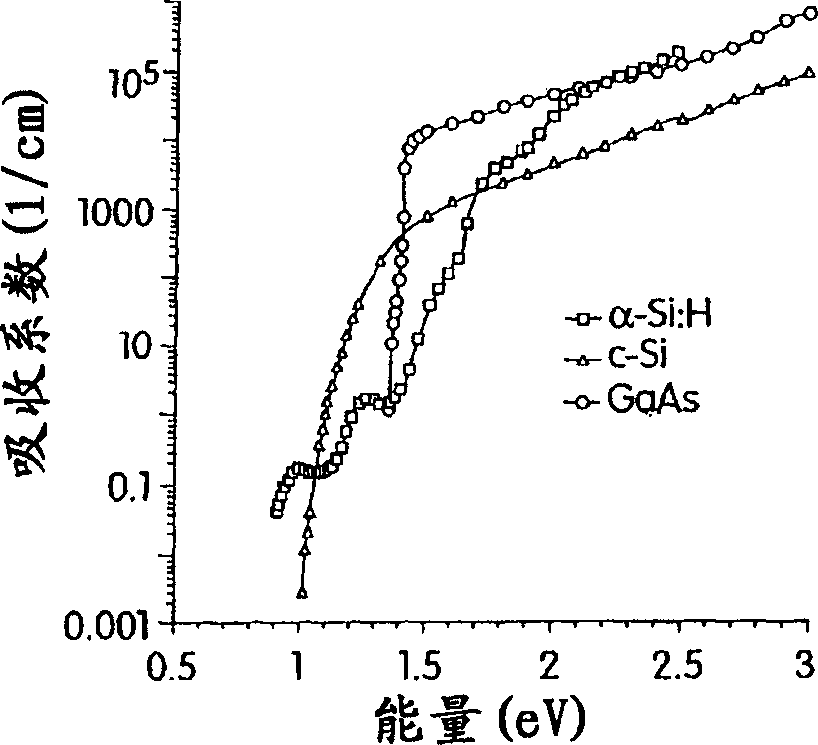

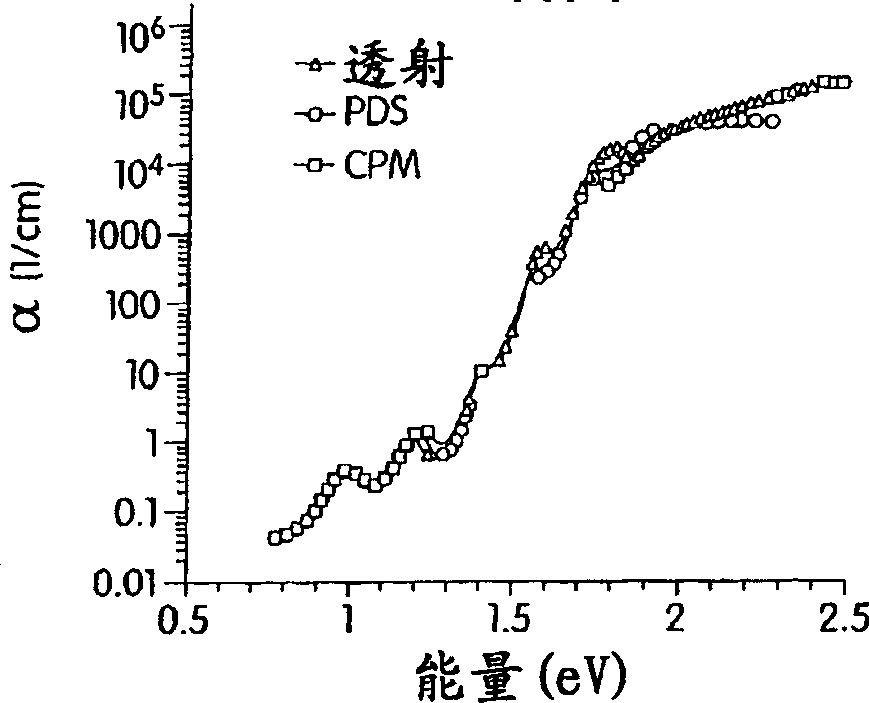

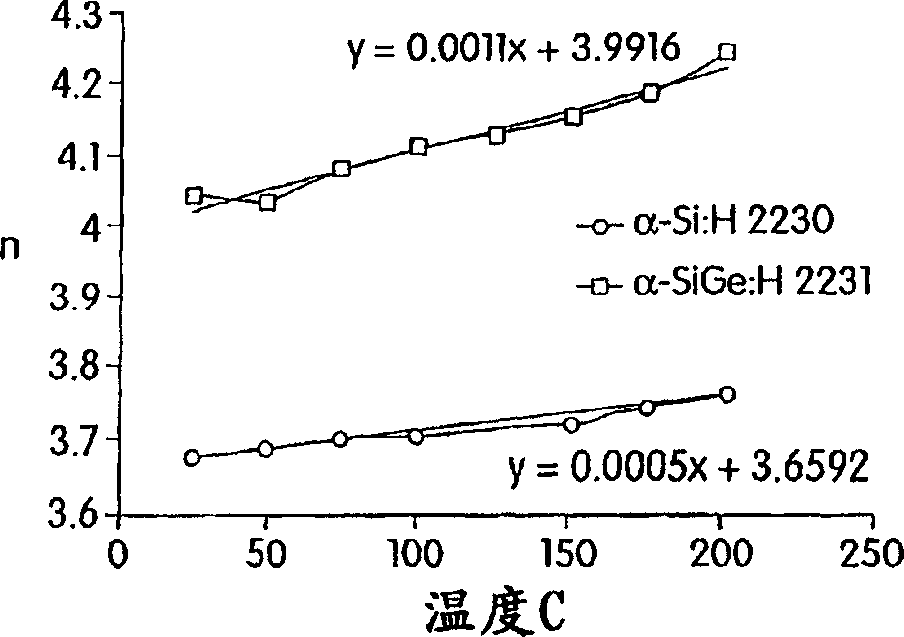

[0067] We have chosen to maximize, rather than minimize, the thermo-optic properties of a particular layer in a TFIC by exploiting the semiconductor thin film in the layer. These layers can be deposited by PECVD or CVD or other variants of PVD. Hydrogen-infused thermo-optic semiconductors such as α-Si:H or alloys for lower optical losses are used as high-refractive index layers (n=3.66 at 1500nm) and deposited by methods that have been optimized for the main optical communication wavelengths near 1500nm highly transparent (extinction coefficient k = 10 -6 ). Refractive index modulations [Delta]n / n of up to 4% can then be brought about by temperature changes over the range 25-45[deg.]C. These large temperature variations are best caused by an optically transparent conductive heating film such as n-type polysilicon adjacent to or alternating with other optical lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com