Cootrol method for temperature system with big lag

A technology of hysteresis temperature and control method, applied in the direction of temperature control, temperature control using electric method, non-electric variable control, etc., can solve the problem of complex dynamic parameter expression, achieve clear physical meaning, reduce mechanical wear and prolong service time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

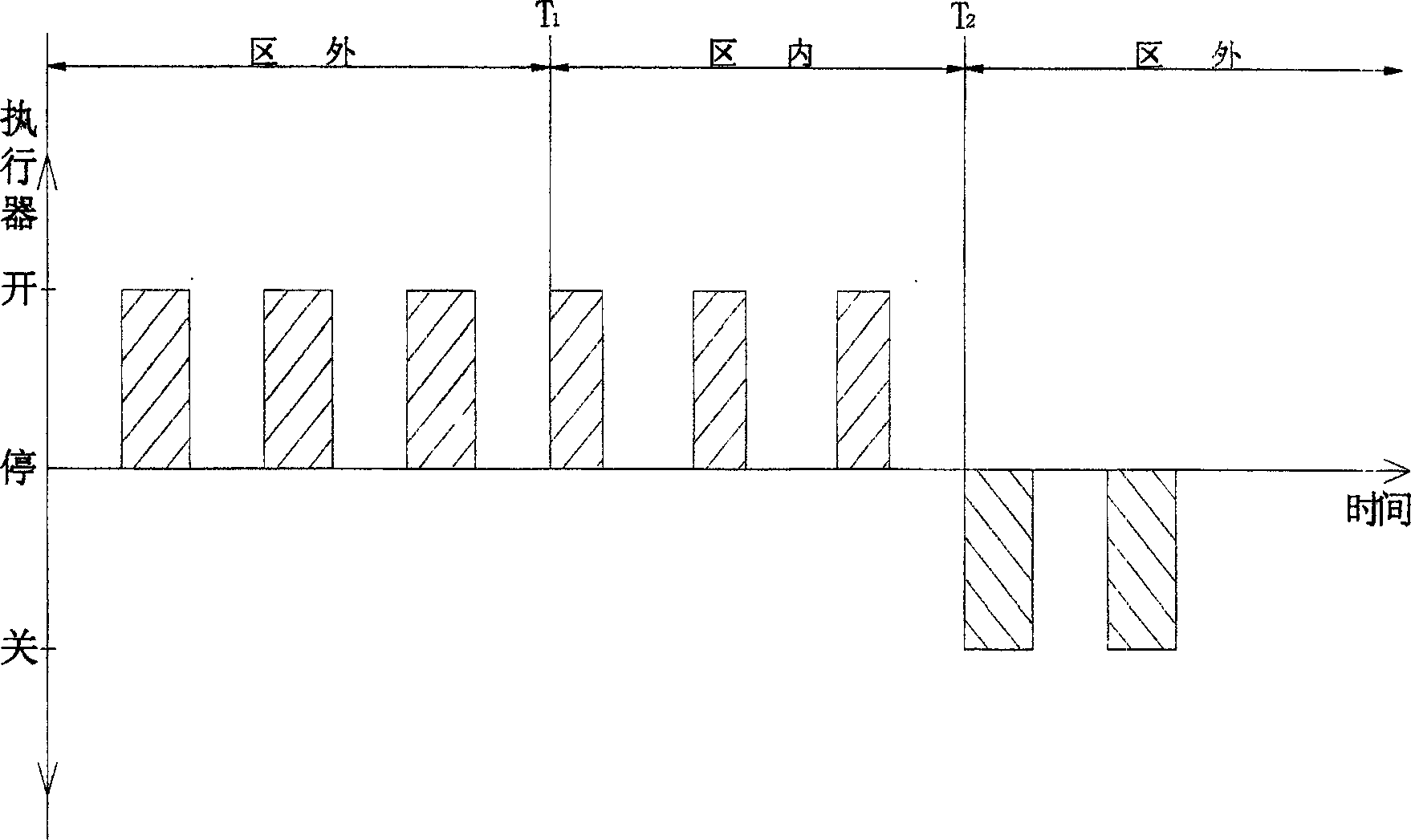

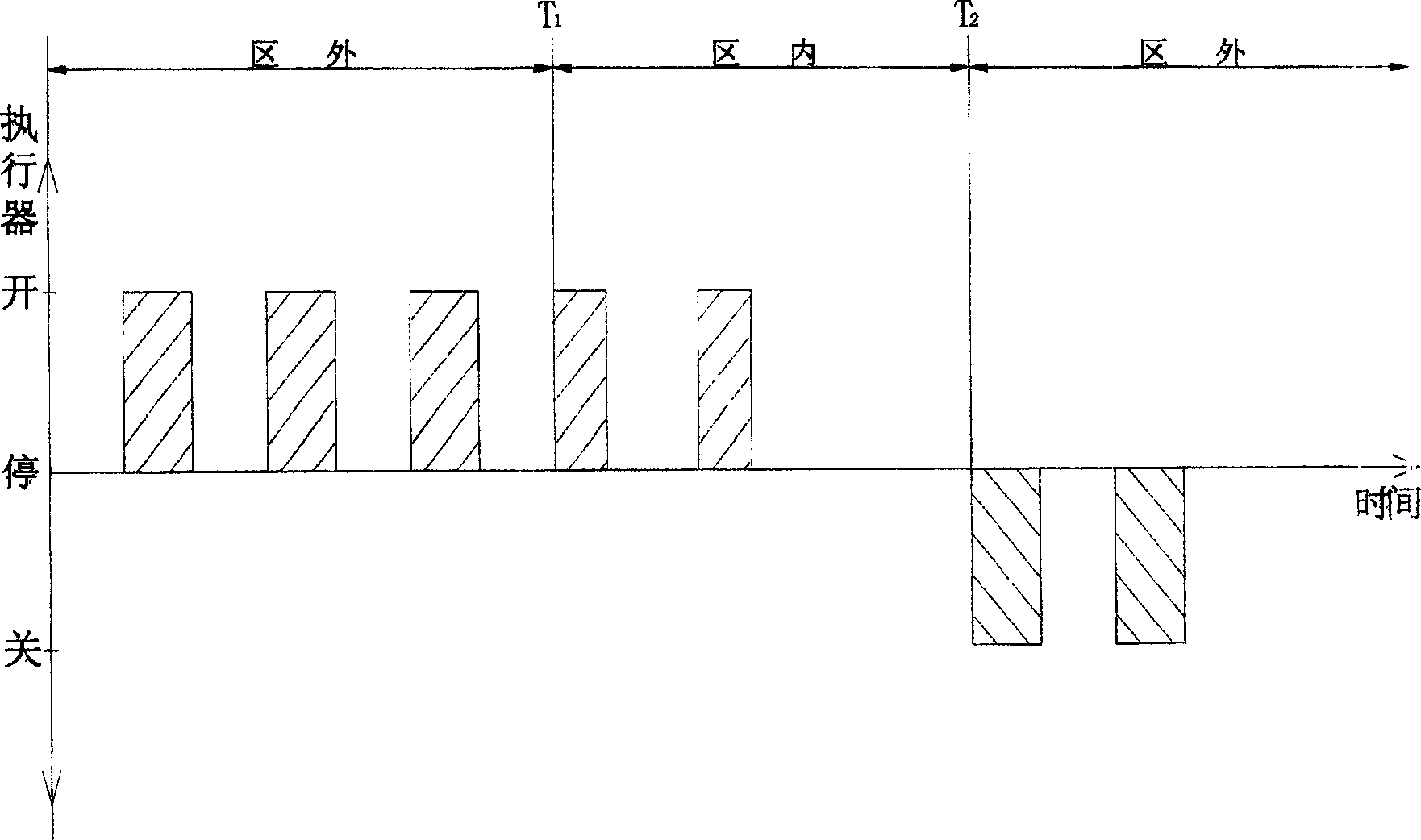

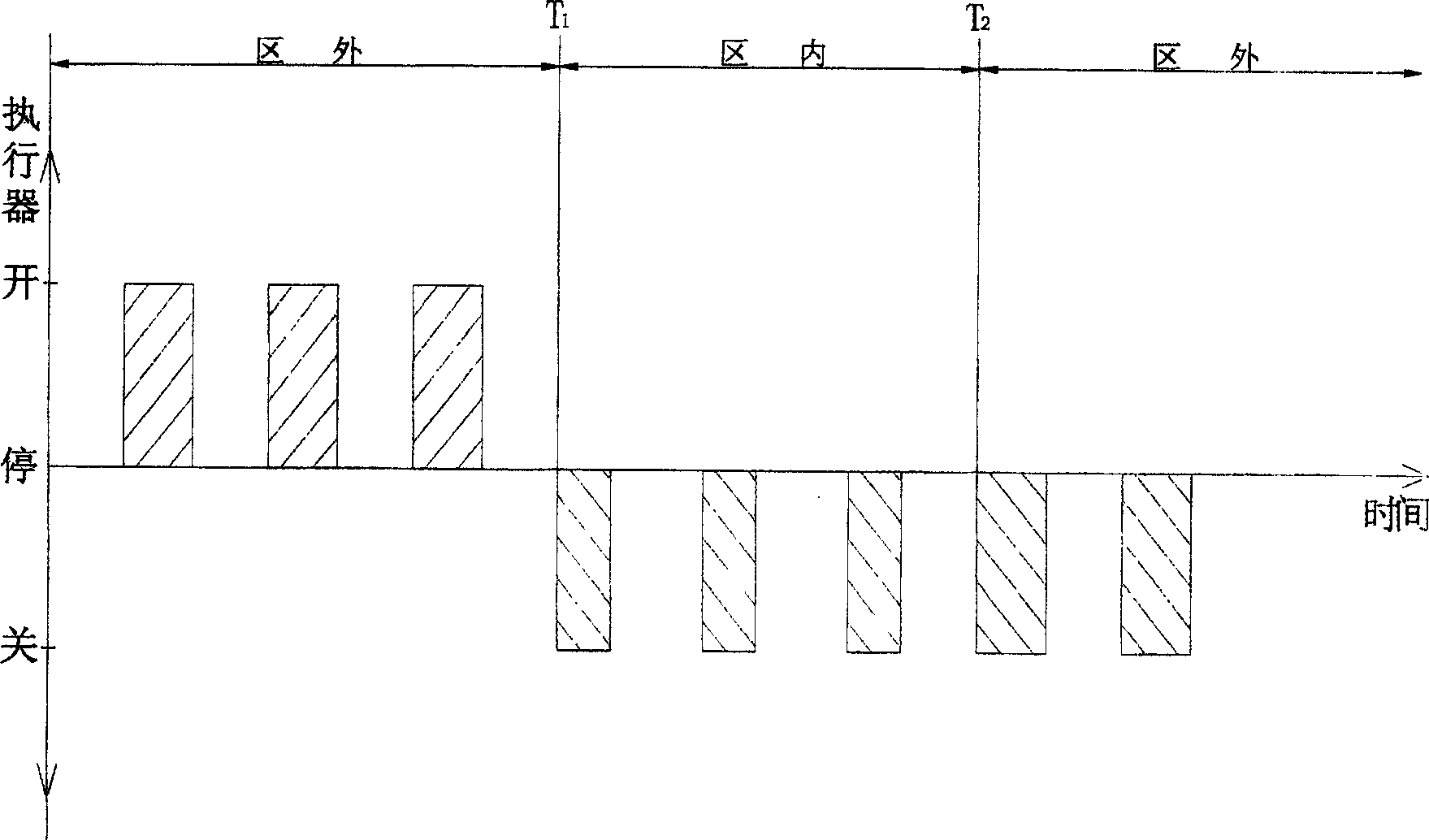

[0020] The control method of the larger hysteresis temperature system disclosed by the present invention can be implemented on the oil field heating furnace (6) by the following temperature control device: the device consists of a burner (5), a controller (1), a temperature sensor (2) , actuator (4), safety valve (3), ignition valve (7), igniter (8), as attached Figure 5 shown. Wherein the fuel of the burner (5) should be gas or liquid, and the burner (5) can be the gas burner described in Chinese patent application 02294106.1 or other gas or oil burners that can realize the combustion function. The controller (1) is a microprocessor-based device with a specific program. The temperature sensor (3) is a temperature switch, which can be a temperature relay, or a relay switch signal converted by a thermocouple, a thermal resistance and other temperature measuring elements through a secondary instrument. The actuator (4) is a motor-driven valve, such as an electric disc valve, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com