Press fitting type spring connector

A connector and push-type technology, applied in the direction of clamping/spring connection, connection, fixed connection, etc., can solve problems that may not ensure stable electrical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

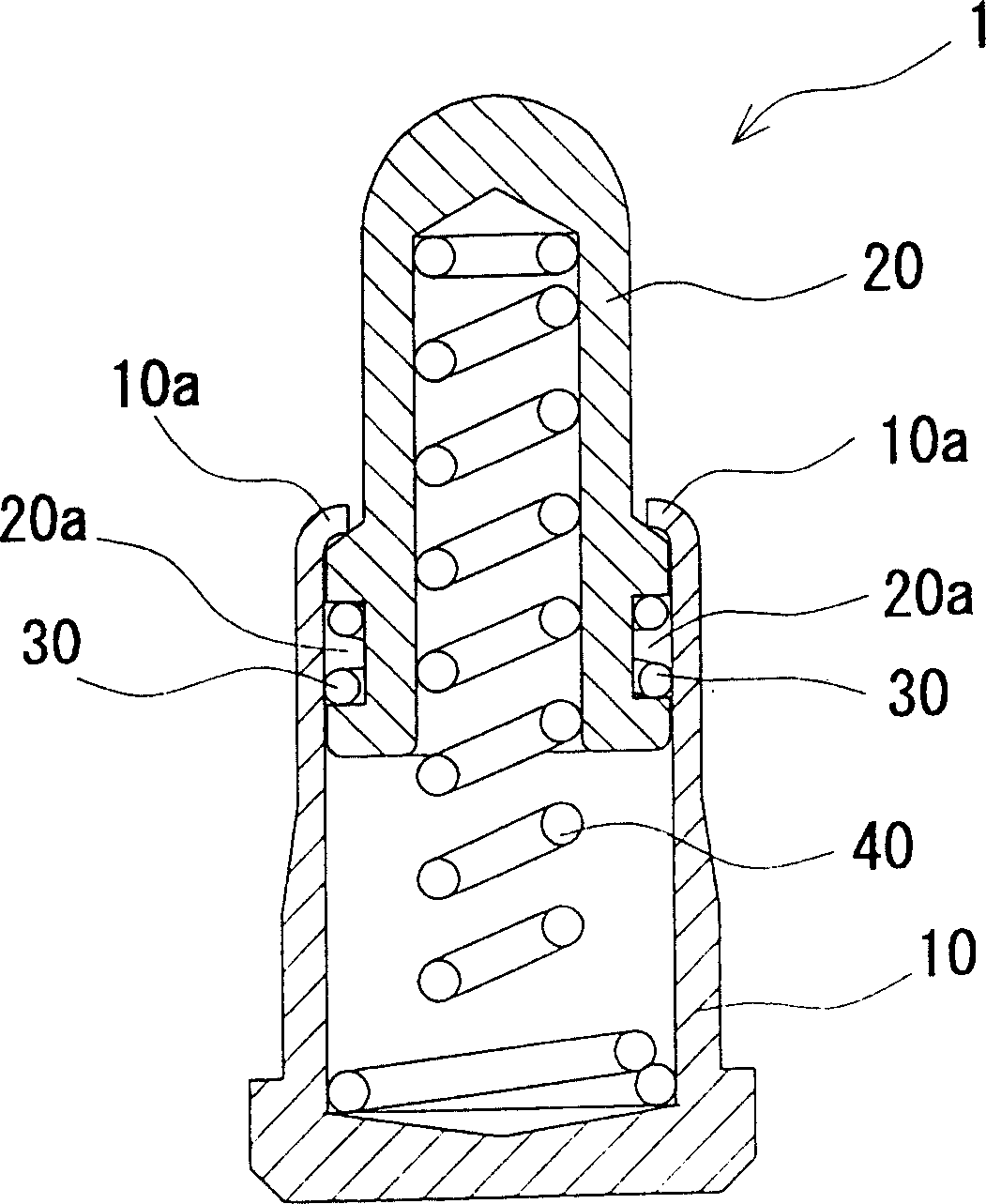

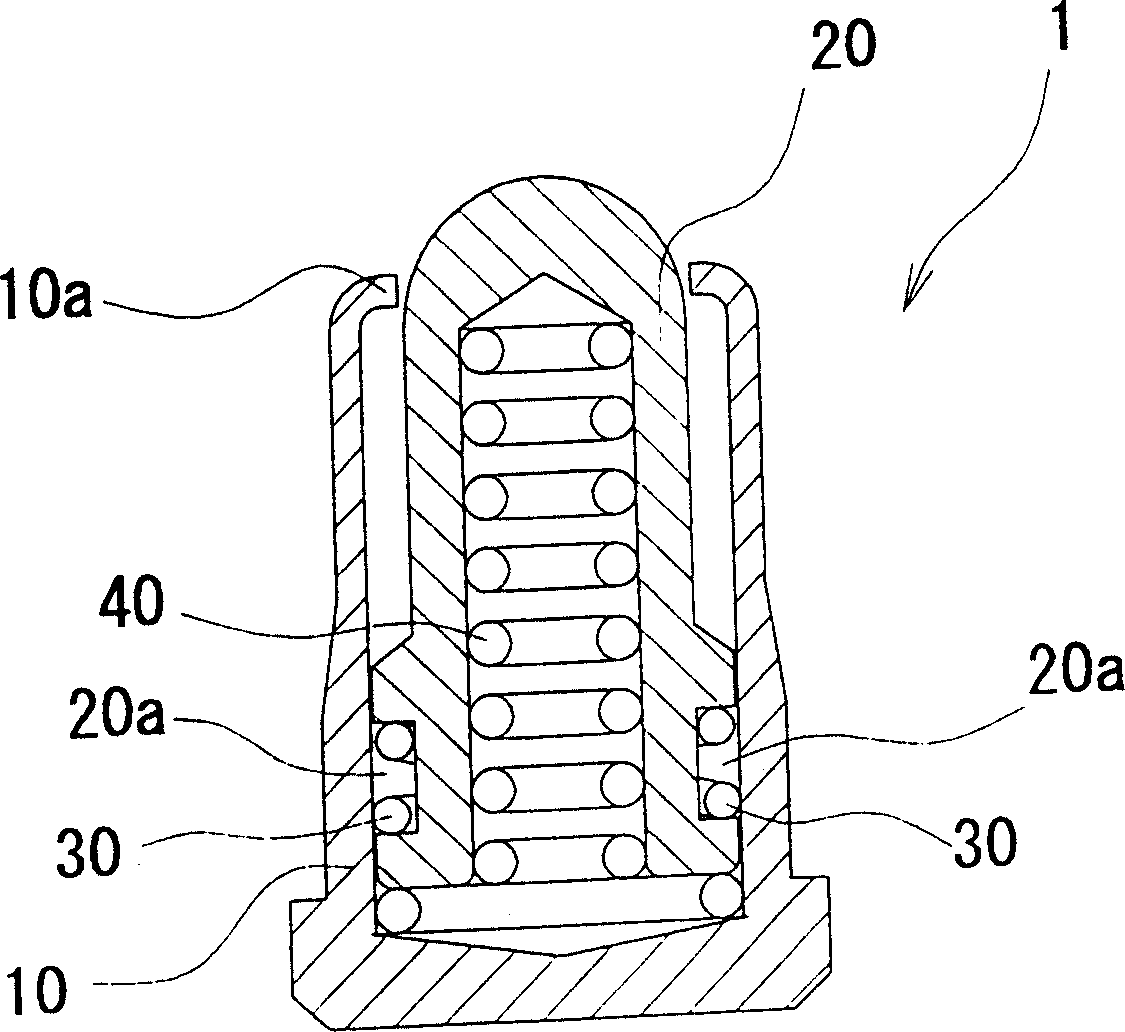

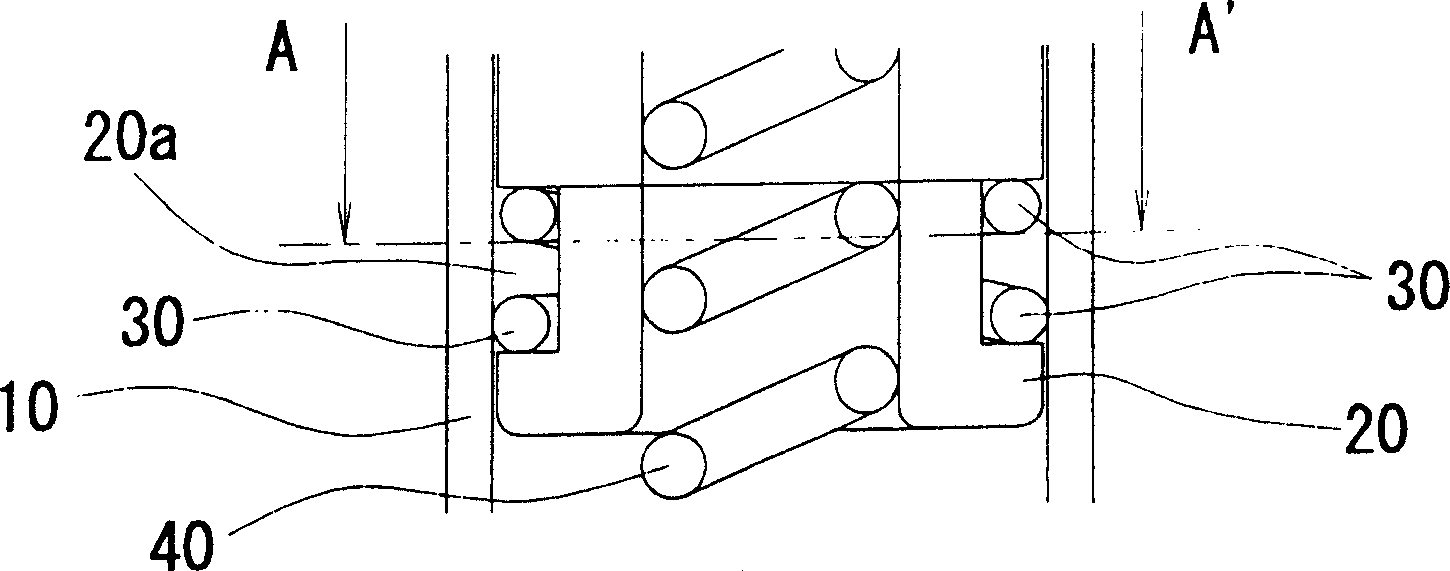

[0015] A push-type spring connector 1 according to an embodiment of the present invention is composed of a barrel 10 , a contact pin 20 , a contact ring 30 , and a coil spring 40 .

[0016] Such as figure 1 and figure 2 As shown, the cartridge 10 is constituted by a cylindrical body, and a space is provided inside. One end is designed as an opening, and the edge of the opening is provided with a pin-limiting portion 10a that shrinks toward the inside. The other end is made into a plane perpendicular to the axis of the cylinder 10 by deforming the edge. Inside the barrel 10 is provided a contact pin 20 .

[0017] One end of the barrel 10 of this embodiment is closed, and it can also be open at both ends, and the opening is closed with a cover at one end.

[0018] Such as figure 1 and figure 2 As shown, the stylus 20 is formed of a cylindrical body, and a space is provided inside. The front end is made into a hemispherical shape, and the diameter is smaller than the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com