Chip resistor and method for producing the same

A chip resistor, resistive film technology, applied in resistor manufacturing, resistors, thick film resistors, etc., can solve the problems of disconnection of the upper electrode, loose outer coating, and resistance value change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

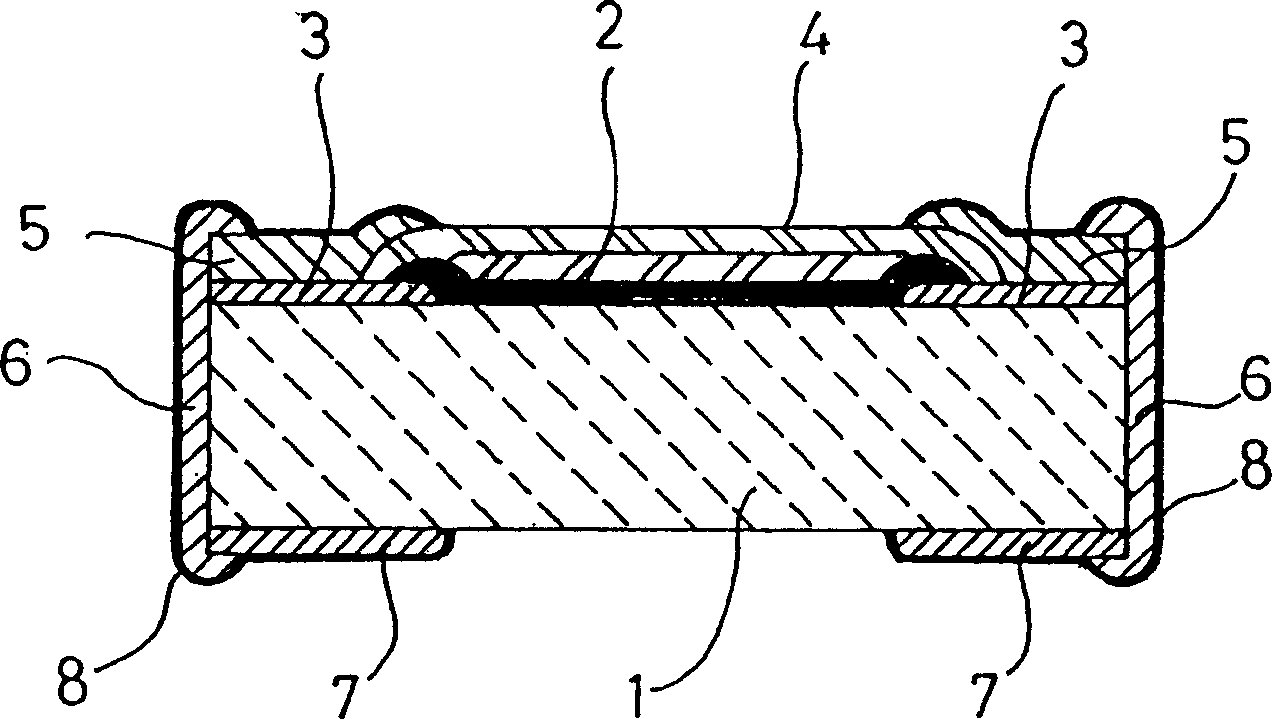

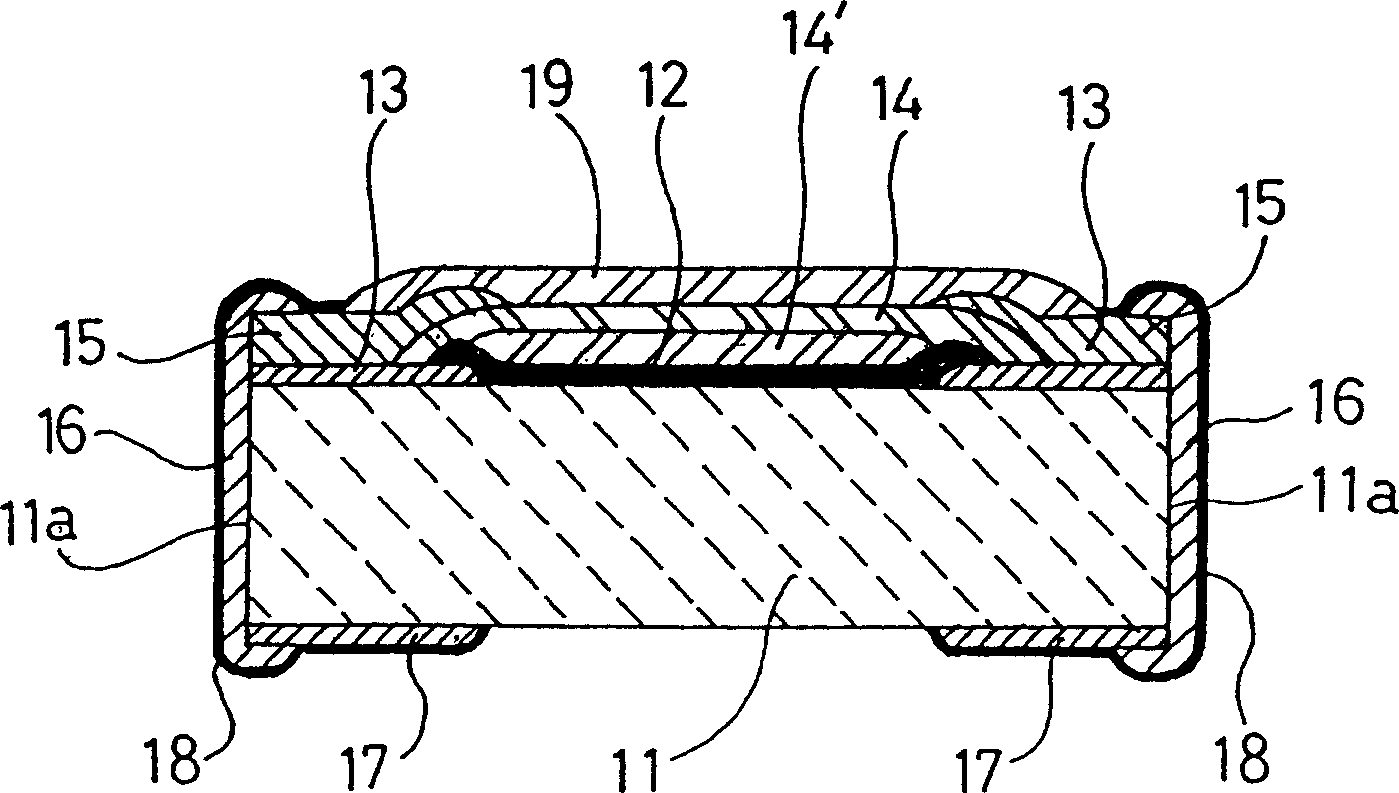

[0024] figure 2 A chip resistor representing an embodiment of the present invention.

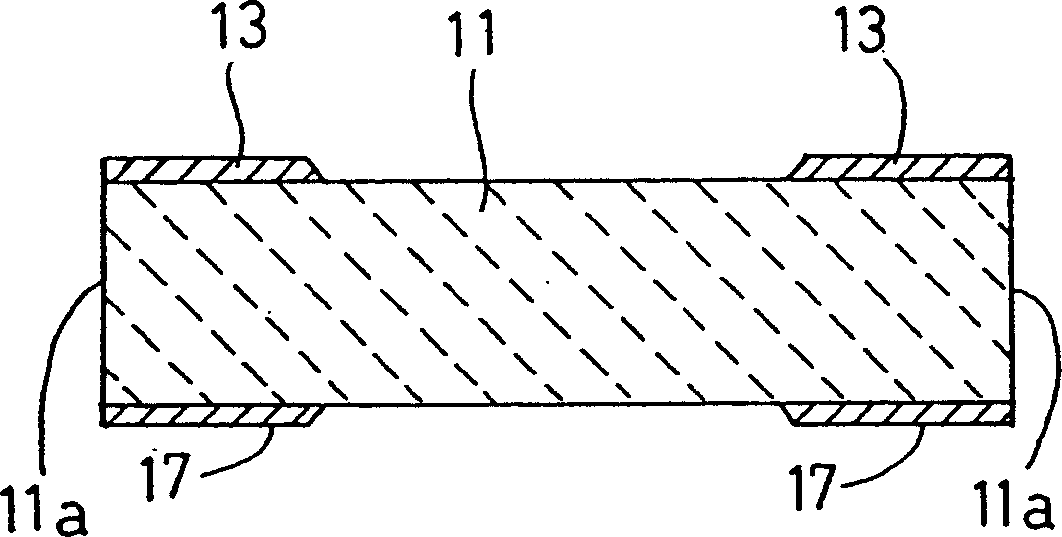

[0025] In the chip resistor of this embodiment, a pair of left and right lower electrodes 17 are formed with silver paste on the underside of a chip-shaped insulating substrate 11, and a resistive film 12 and a resistive film 12 are formed on the upper surface of the insulating substrate 11. The top electrodes 13 made of silver paste at both ends of the film 12, and an overcoat layer 14 made of glass or the like covering the above-mentioned resistive film 12 is formed; on the top of the above-mentioned two top electrodes 13, a part overlaps with respect to the above-mentioned overcoat layer 14 The auxiliary upper surface electrode 15 is formed by silver paste, by a conductive paste mainly composed of base metals such as nickel or copper, or by a curable conductive resin paste descri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com