Preparation method of wolframium sintered body

A technology of tungsten-aluminum alloy and sintered body, which is applied in the field of preparation of tungsten-aluminum alloy sintered body, to achieve the effects of inhibiting oxidation behavior, convenient operation, and short sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

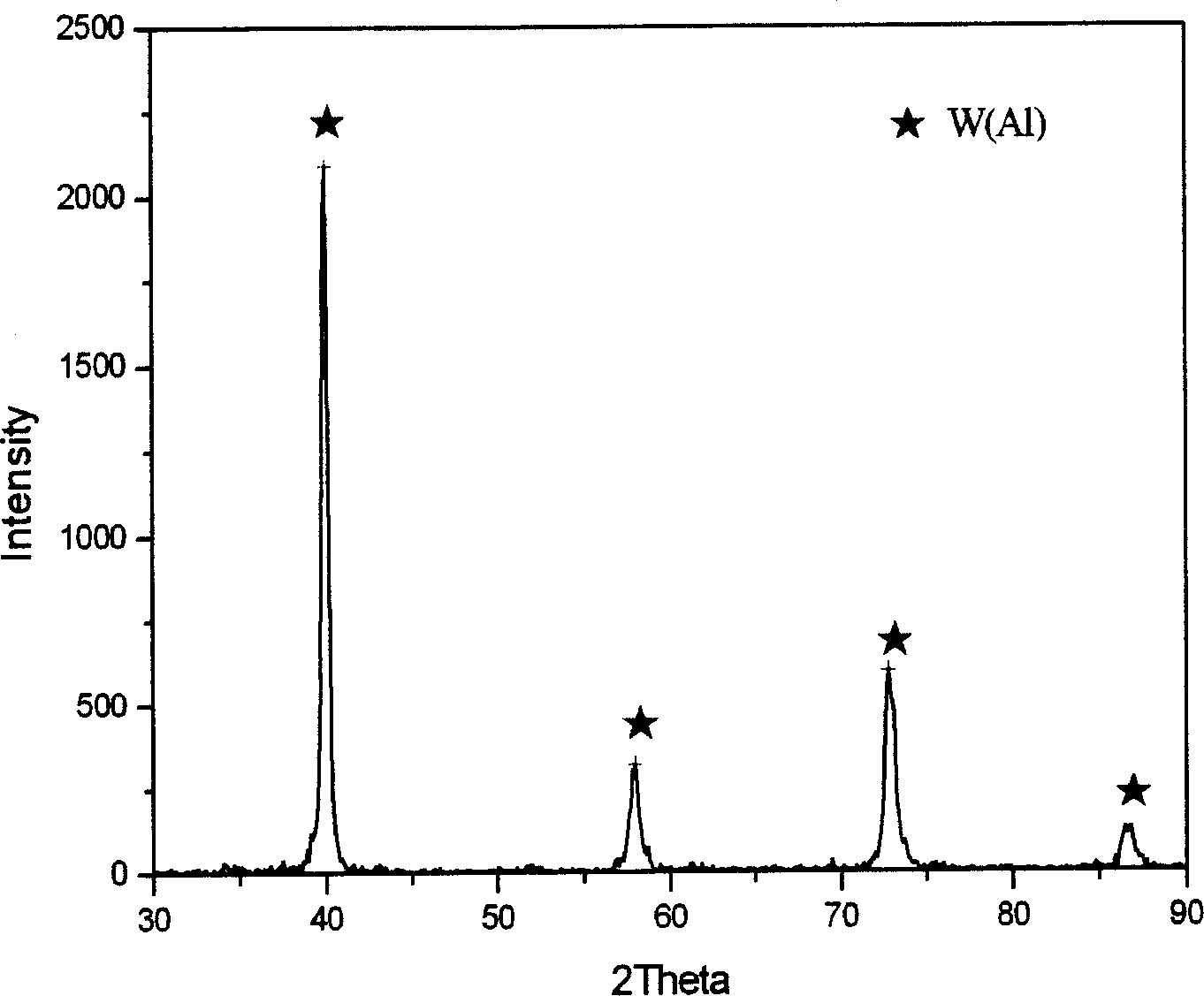

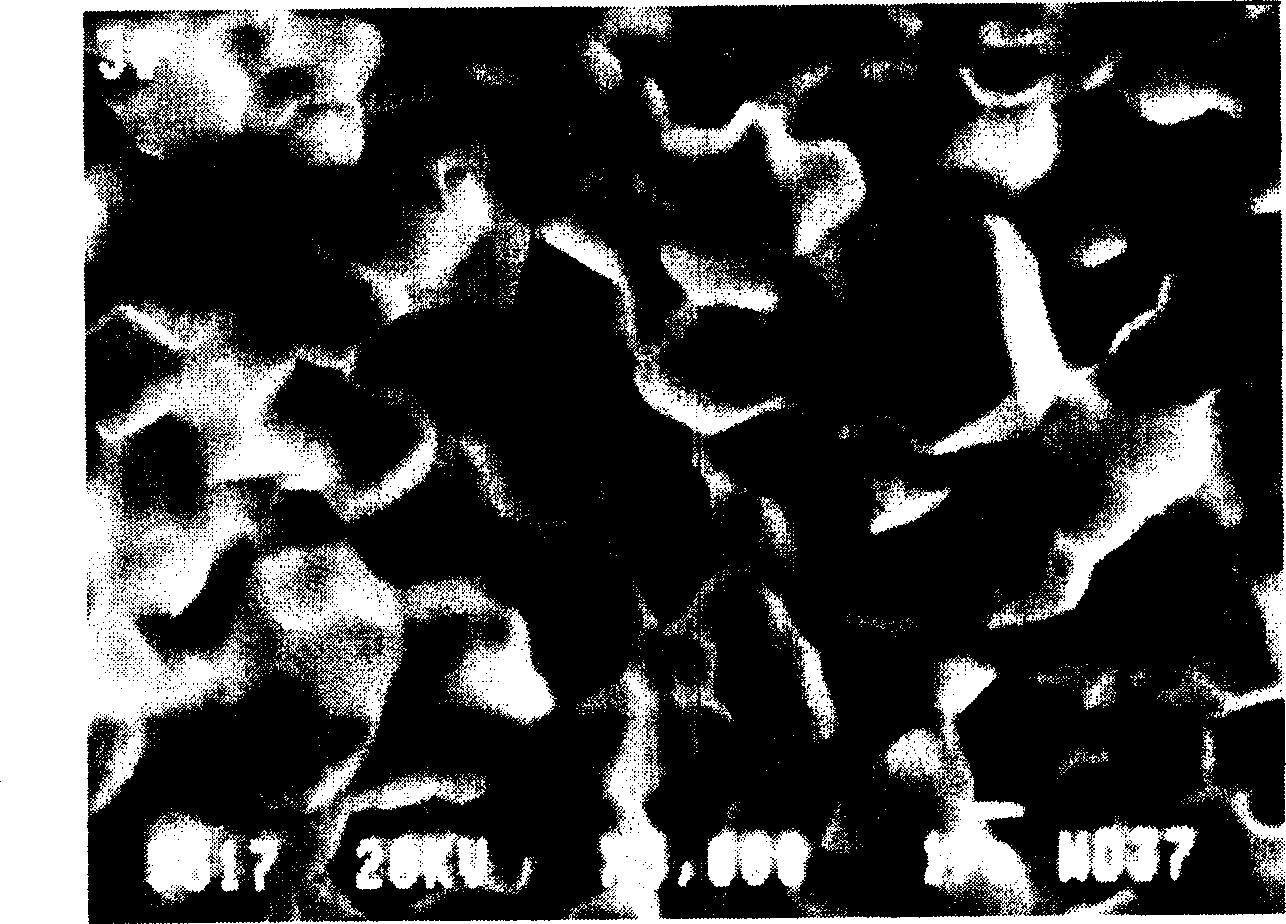

[0008] Embodiment 1: the weight is 35 grams, the W of particle size less than 100 nanometer 0.9 Al 0.1 The powder is put into a graphite mold, and the vacuum pressure is less than 10 -2 Sintering under the condition of MPa, the sintering temperature is 1600°C, the pressure is 40MPa, and the sintering time is 60 minutes. After the sample is polished and analyzed, the relative density is 98.2%, the compressive strength is 1730MPa, the bending strength is 480Mpa, the elastic modulus is 60GPa, and the microhardness is 720Hv.

Embodiment 2

[0009] Embodiment 2: the weight is 32 grams, the W 0.8 Al 0.2 The powder is put into a graphite mold, and the vacuum pressure is less than 10 -2 Sintering under the condition of MPa, the sintering temperature is 1500°C, the pressure is 30MPa, and the sintering time is 45 minutes. After the sample is polished and analyzed, the relative density is 99.2%, the compressive strength is 1862MPa, the bending strength is 493Mpa, the elastic modulus is 65GPa, and the microhardness is 760Hv.

Embodiment 3

[0010] Embodiment 3: the weight is 30 grams, the W of particle size less than 100 nanometer 0.6 Al 0.4 The powder is put into a graphite mold, and the vacuum pressure is less than 10 -2 Sintering under the condition of MPa, the sintering temperature is 1400°C, the pressure is 30MPa, and the sintering time is 30 minutes. After the sample is polished and analyzed, the relative density is 99.5%, the compressive strength is 2043MPa, the bending strength is 520Mpa, the elastic modulus is 50GPa, and the microhardness is 778Hv.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com