Method for enhancing bonding strength of dental titanium porcelain through depositing nanometer niobium nitride

A combination strength, nano-scale technology, applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problem of long-term clinical reports of titanium porcelain restorations, lack of protection and adhesion, and titanium porcelain restorations. failure and other problems, to achieve good clinical application prospects, easy access to related materials and equipment, and the effect of inhibiting oxidation behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Use X-rays to screen 30 pure titanium substrates without casting defects, the size of which is 25mm×3mm×0.5mm, remove surface impurities with a tungsten carbide grinding head, and polish the pure titanium substrates. The grinding head speed is ≤15000rpm. After the polishing process is finished, the pure titanium substrate is placed in the air for self-passivation treatment, the passivation time is 10 minutes, and then the pure titanium substrate is cleaned with hot steam for 5 minutes, and then ultrasonically cleaned with acetone 15 minutes, and finally blow dry with pure nitrogen.

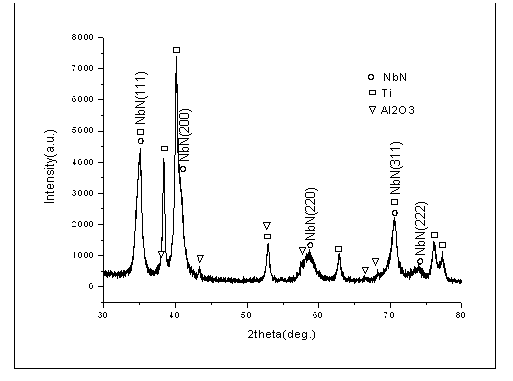

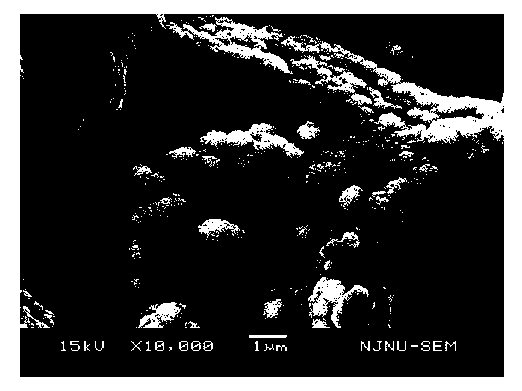

[0032] At 2bar pressure, with 120μmAl 2 o 3 The particles perform sandblasting on the pure titanium substrate, the distance between the sandblasting nozzle and the pure titanium substrate is 10 mm, the sandblasting angle is 45°, and the sandblasting time is 5 minutes. After the sandblasting treatment, the pure titanium substrate was cleaned again, still first cleaned with hot steam for 5 ...

Embodiment 2

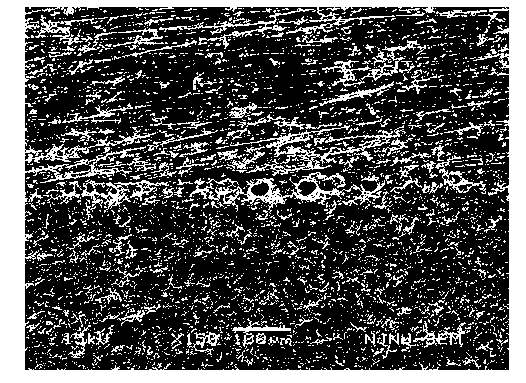

[0040] In this specific embodiment, the pre-processing method of the pure titanium substrate is the same as that of the first embodiment, and will not be repeated here. The difference between the second embodiment and the first embodiment is that niobium nitride is not carried out on the surface of the pure titanium substrate. For deposition, directly perform porcelain sintering on the pure titanium substrate that has been sandblasted and cleaned and dried, and the porcelain sintering procedure is carried out according to the specifications of the selected porcelain powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com