Hydrothermal synthesis method for producing Nano sheet material of stannous oxide

A stannous oxide, hydrothermal synthesis technology, applied in the direction of tin oxide, etc., can solve the problem of not being able to obtain stannous oxide nanomaterials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

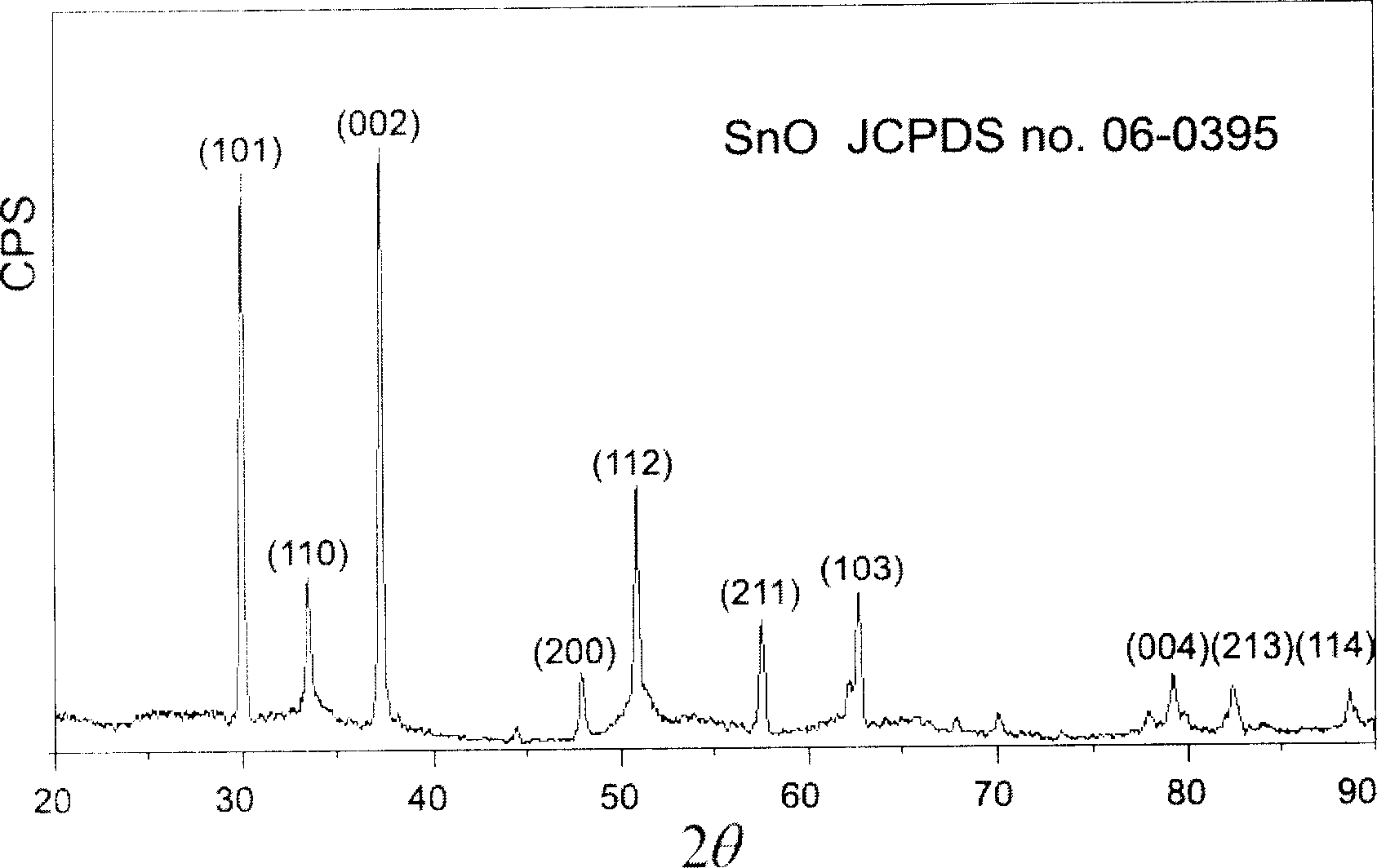

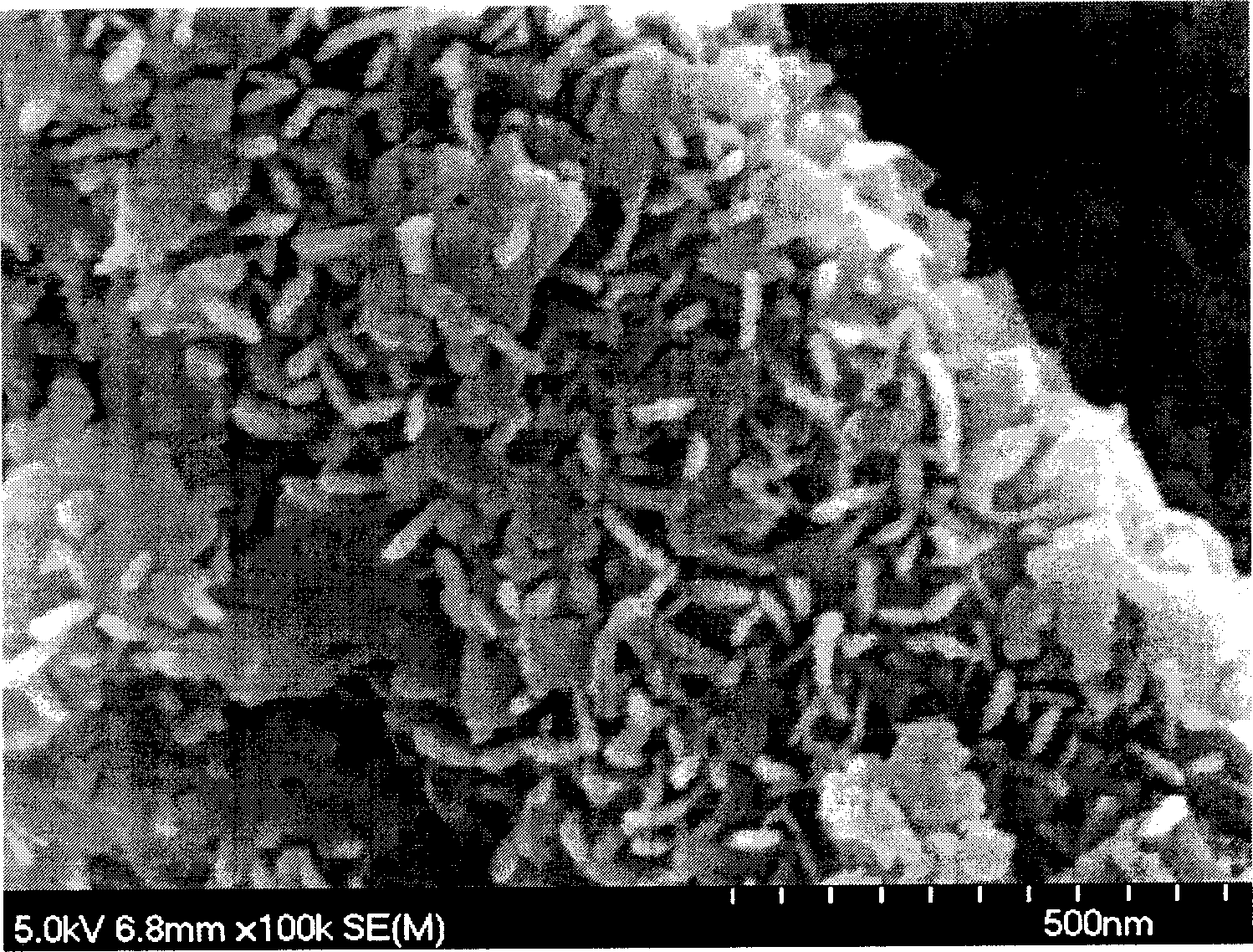

[0020] 0.90 g of stannous chloride (SnCl 2 2H 2 (0) be dissolved in 100 milliliters of mass concentration and be in the polyethylene glycol solution of 5%, stannous chloride molar concentration 0.04 mol / liter, after stirring for 5 minutes, add 2.35 gram concentration again and be 85% hydrazine hydrate (N 2 h 4 ·H 2 (0), the hydrazine hydrate molar concentration is 0.4 mol / liter, and after stirring for 5 minutes, the above-mentioned prepared solution is put into the polytetrafluoroethylene lining of the autoclave, and the lining volume is 120 milliliters. The solution is treated at 120° C. for 10 hours, and the treated solution is centrifuged and dried to obtain a stannous oxide nanosheet structure with a thickness of about 15 nanometers, and the width of the flakes is about 100-300 nanometers. figure 1 It is the XRD pattern of the SnO nanoflakes, which is completely consistent with the standard card of SnO (JCPDS no.06-0395). There are no peaks of impurities such as tin oxi...

Embodiment 2

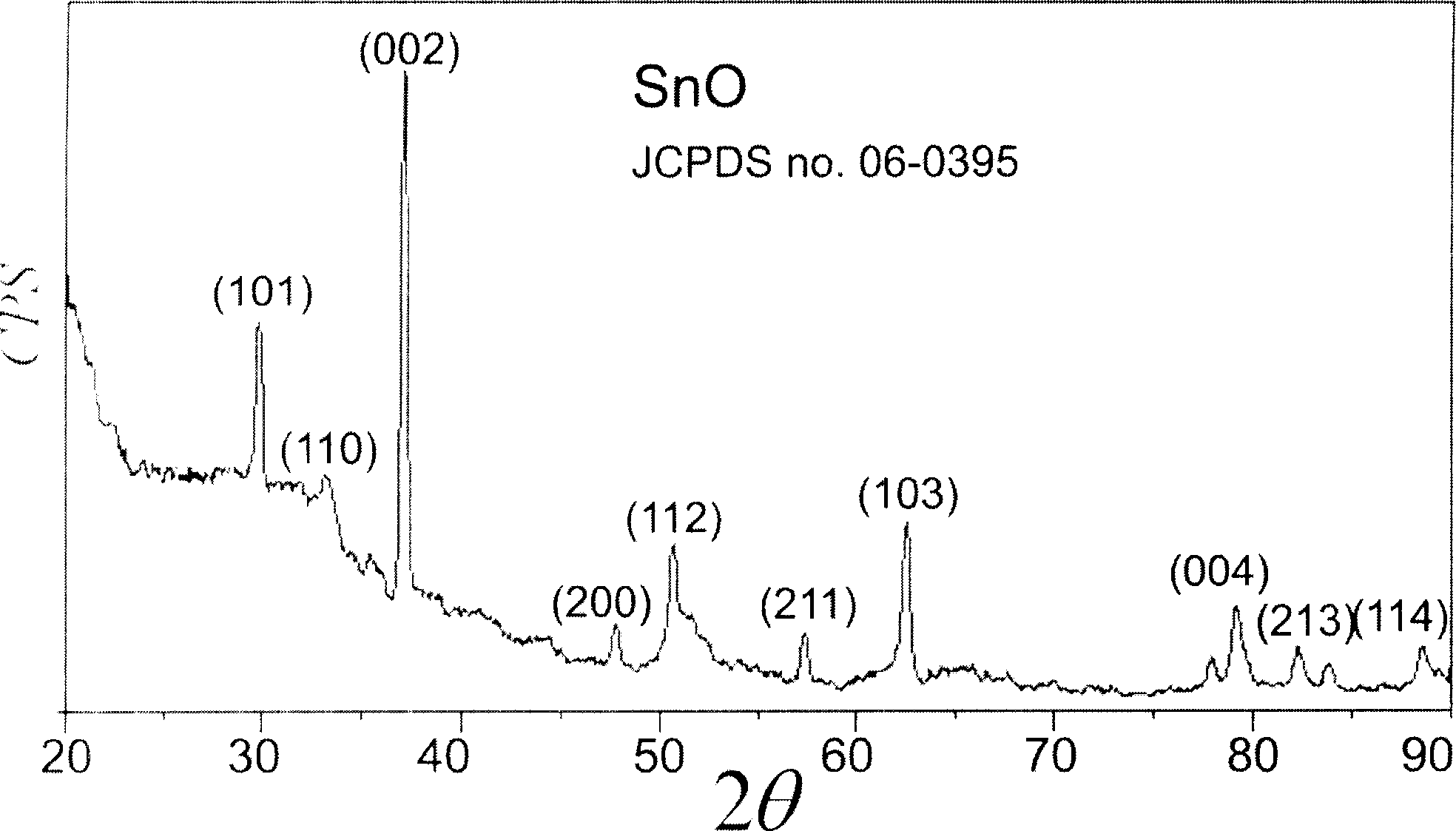

[0022] 0.90 g of stannous chloride (SnCl 2 2H 2 O) being dissolved in 100 milliliters of citric acid solution with molar concentration of 0.01 mol / liter, stannous chloride molar concentration of 0.04 mol / liter. After stirring for 5 minutes, adding 0.94 gram of concentration is 85% hydrazine hydrate (N 2 h 4 ·H 2 (0), the hydrazine hydrate molar concentration is 0.16 mol / liter, after stirring for 5 minutes, the above-mentioned prepared solution is put into the polytetrafluoroethylene inner lining of autoclave, and inner lining volume is 120 milliliters. The solution was treated at 120° C. for 18 hours, and the treated solution was centrifuged and dried to obtain a stannous oxide nanoflake structure with a thickness of about 30 nanometers, and the width of the flakes was smaller than that of the product obtained in Example 1. image 3 It is the XRD pattern of the SnO nanoflakes, which is completely consistent with the standard card of SnO (JCPDS no.06-0395). There are no pea...

Embodiment 3

[0024] 2.26 grams of stannous chloride (SnCl 2 2H 2 O) be dissolved in 100 milliliters of molar concentrations and be 0.025 mol / litre in the citric acid solution, tin protochloride molar concentration 0.10 mol / litre, stir after 5 minutes, then add 4.7 gram concentrations and be 85% hydrazine hydrate (N 2 h 4 ·H 2 (0), the hydrazine hydrate molar concentration is 0.80 mol / liter, and after stirring for 5 minutes, the above-mentioned prepared solution is put into the polytetrafluoroethylene lining of the autoclave, and the lining volume is 120 milliliters. The solution was treated at 150° C. for 24 hours, and the treated solution was centrifuged and dried to obtain a stannous oxide nanosheet structure with a thickness of about 30 nanometers. Figure 5 It is the XRD pattern of the SnO nanoflakes, which is completely consistent with the standard card of SnO (JCPDS no.06-0395). There are no peaks of impurities such as tin oxide in the figure, indicating that the product is pure s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com