Electric cooker

An electric rice cooker and pot body technology, which is applied to cooking utensils, household utensils, applications, etc., can solve the problems of easy damage to the pot body, inconvenient cleaning, poor integrity of the outer surface, etc. New, overall improved effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

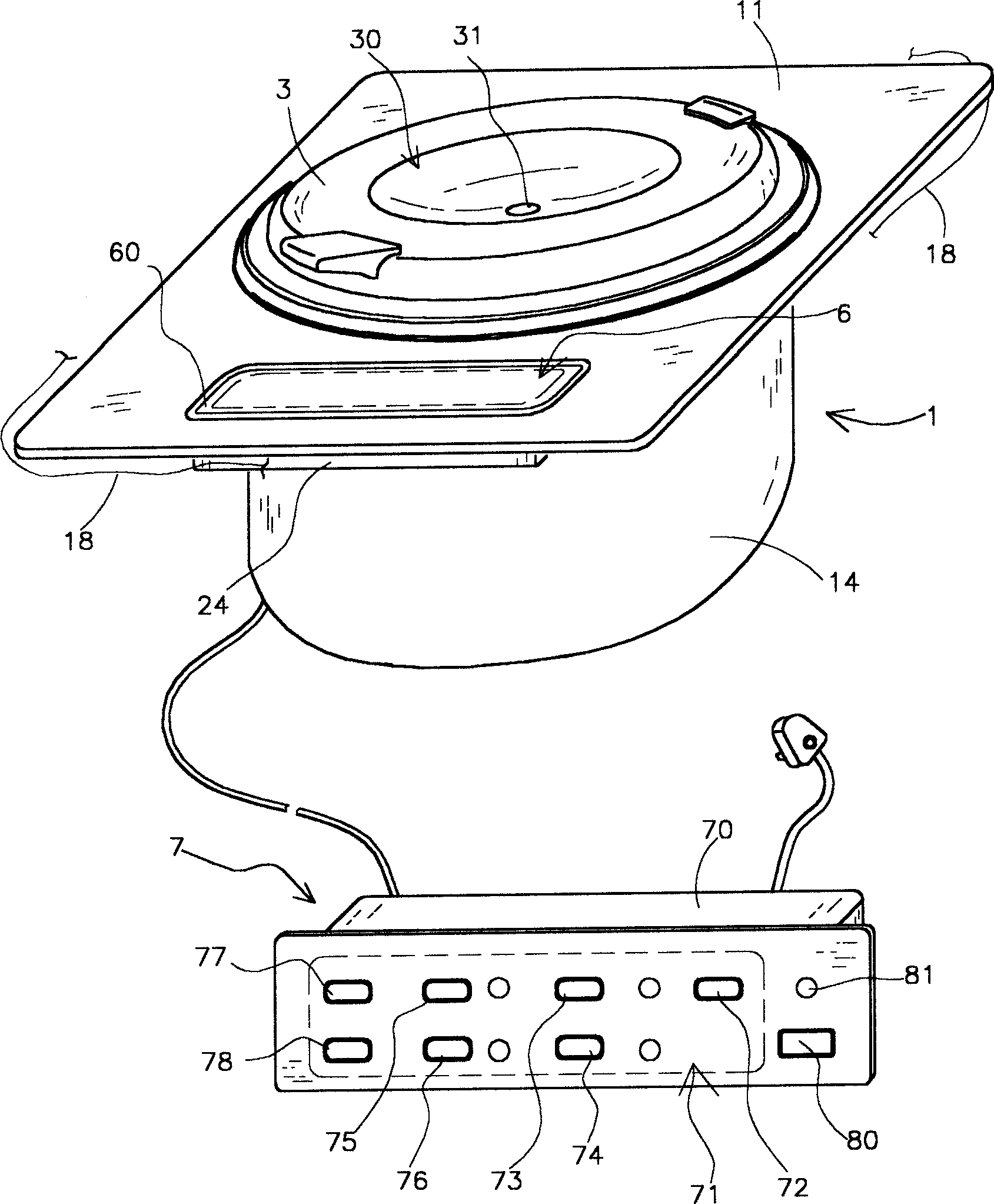

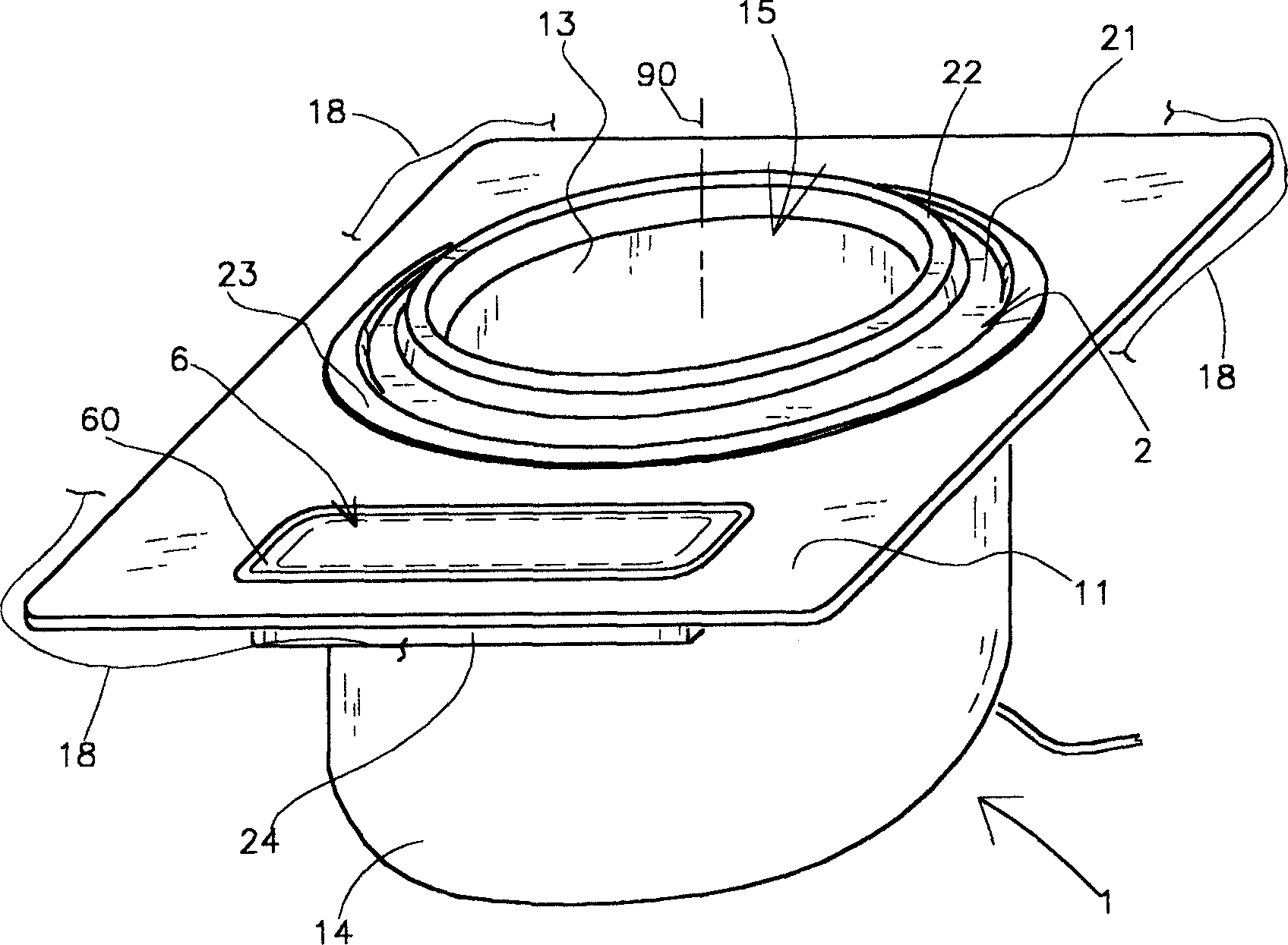

[0042] Electric rice cooker of the present invention, see attached Figure 1~6 , Shown in 13, electric rice cooker is made of pot body, inner pot, electric heating device, electric drive display portion, control device, cover body etc.

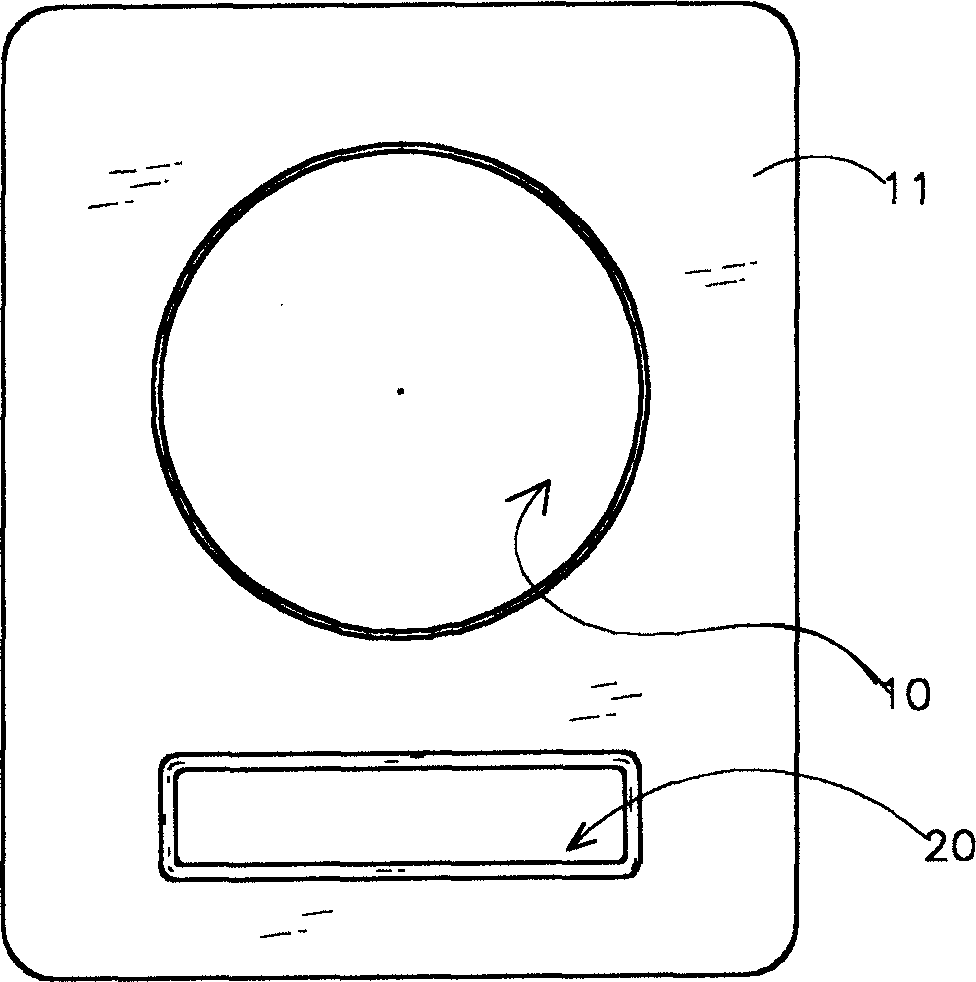

[0043] Such as Figure 1~6 , Shown in 13, there is a panel 11 of a rectangular metal material that is a quadrangular arc on the upper end surface of the above-mentioned pot body 1, and the panel 11 is a constituent of the pot body 1. See details image 3 , 6 As shown, there is a through hole 10 on the panel 11, and there is an upward slope on the side of the through hole 10, which can play a water blocking effect. There is an annular metal guard ring 21 at the position of the through hole 10 on the pot body 1, and the inner peripheral mouth 25 of the guard ring 21 has a downwardly extending edge, and there is a cylindrical shell 13 with an upper opening made of metal in the pot body 1. , the upper opening of the shell has an outward folded...

Embodiment 2

[0060] Its structure of the electric rice cooker of this example is basically identical with embodiment 1, and roughly with reference to Figure 1~6 , 13, its structural characteristics are as follows Figure 7 shown. This example Figure 7 The shown solid metal ring disk-shaped grommet 21 (the grommet is generally similar to the shell-shaped grommet 21 in Embodiment 1) located at the through hole 10 has an annular groove 2 on the grommet; the panel 11 has a The upper convex ring edge 32 slightly higher than the board surface outside the through hole 10 .

[0061] Figure 7 As shown, during assembly, there are corresponding process holes and fastening holes at the bottom of the retaining ring 21, the inverted L-shaped upper fold edge of the upper opening of the shell 13, and the side of the through hole 10 of the panel 11 (the position 33 as shown in the figure). Screws and backing rings are used for fastening (not shown in detail), and the retaining ring 21 is fastened to...

Embodiment 3

[0064] The electric rice cooker of this example, its structure is basically identical with embodiment 1, and roughly with reference to Figure 1~6 , 13, and its structural features are shown in Figure 8. In this embodiment, as shown in Figure 8, an annular metal retaining ring 21 with a downwardly extending edge at the inner peripheral opening 25 at the position of the through hole 10, the retaining ring has an annular groove 2 on the upper end surface, and is located in the through hole. There is an annular collar 92 at the hole 10, and the shell in embodiment 1 is replaced by the shell 13 shown in FIG.

[0065] As shown in Figure 8, when assembling, the straight cylinder of the back ring 92 is fitted in the through hole 10 of the panel 11, the lower extending side of the guard ring 21 is fitted in the inner opening of the back ring 92, and on the top of the shell 13 The part where the opening is connected to the inner peripheral mouth 25 of the retaining ring (part 93 as sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com