Automatic evaporator defrosting on-off control method

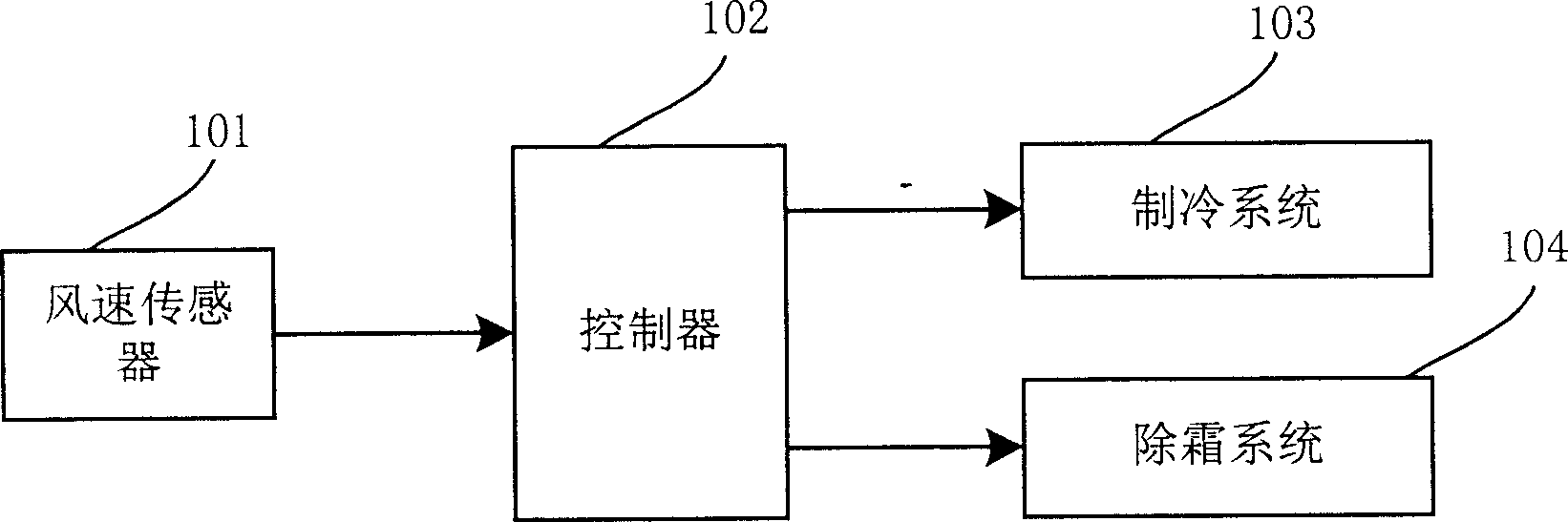

An evaporator and control system technology, applied in defrosting, instruments, refrigerators, etc., can solve the problems of air flow rate drop, can not reflect the overall change of frost layer thickness, surface heat transfer coefficient drop, etc., to achieve the effect of reducing accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

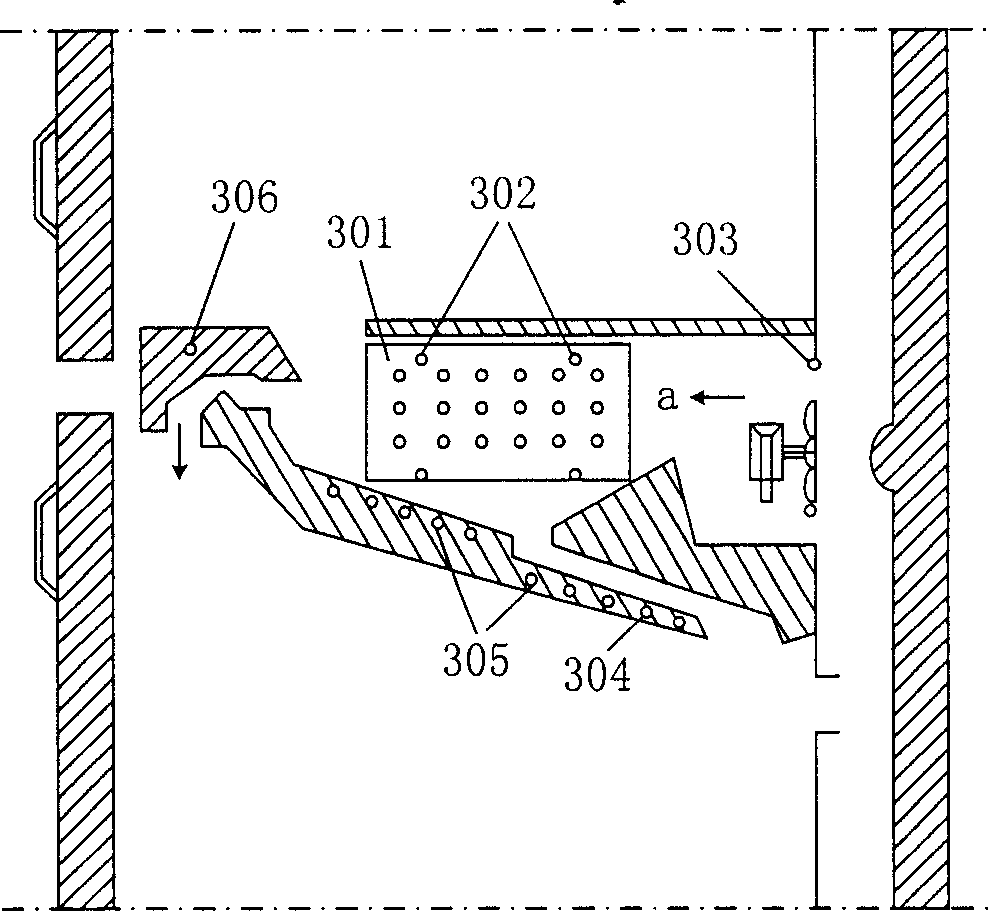

[0036] Example 1: Double-door air-cooled refrigerator evaporator electric heating defrost

[0037] See image 3 , image 3 It is a schematic diagram of the internal distribution of some electric heating devices of a commonly used double-door air-cooled refrigerator. The figure includes: evaporator 301, evaporator defrost heater 302, fan blade hole heater 303, drain pipe heater 304, and Water tray heater 305, temperature-sensitive damper thermostat housing heater 306.

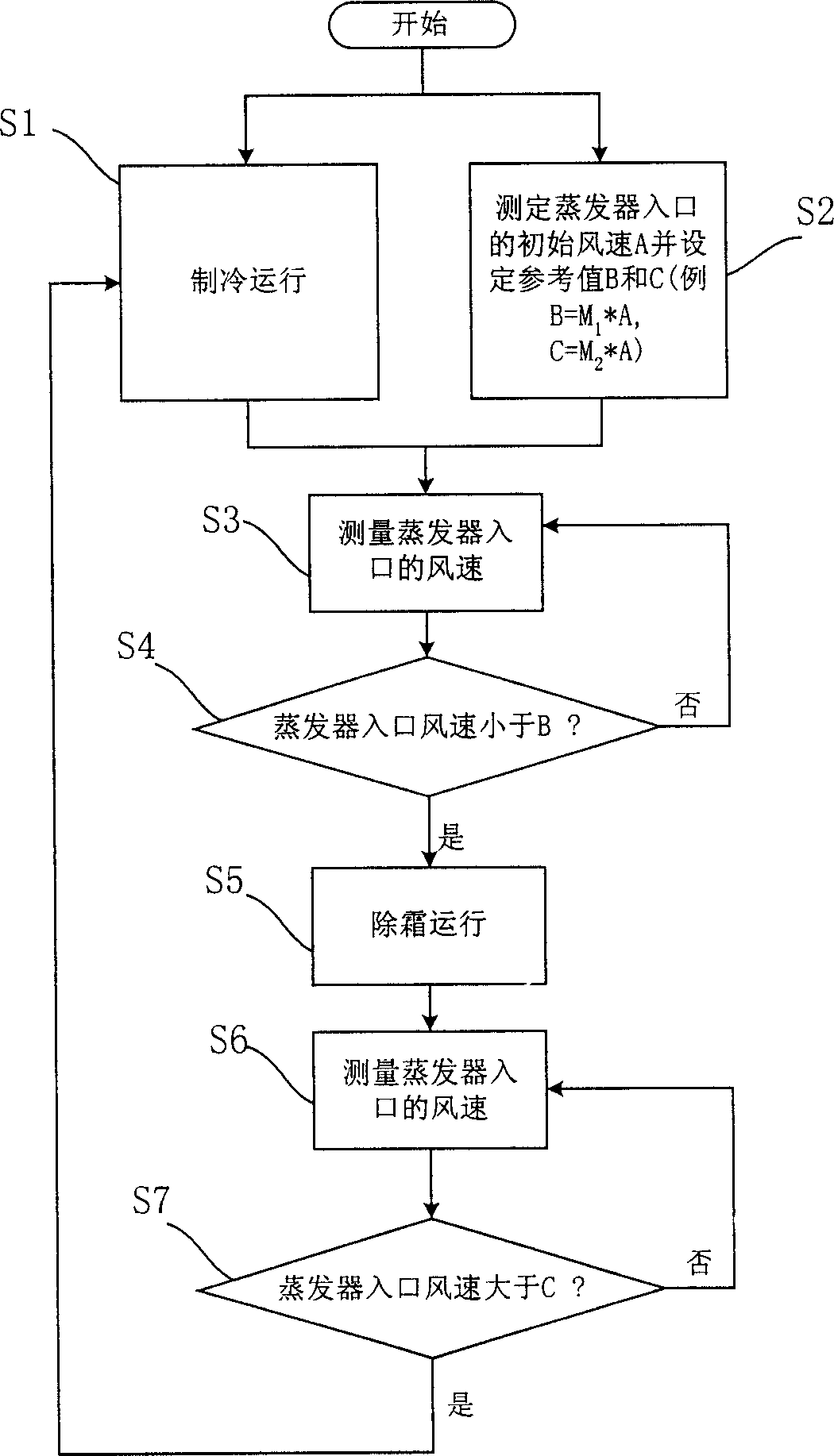

[0038] The evaporator 301 is located between the freezer compartment and the refrigerating compartment. Using the method of the present invention to automatically determine the defrosting start time, a wind speed sensor 101 is installed at the entrance position a of the evaporator 301. When the refrigerator is turned on and enters the cooling operation (step S1) The wind speed sensor 101 measures the initial wind speed A at the entrance of the evaporator, and sets reference values B and C (step S2, B and C can be ...

Embodiment 2

[0039]Example 2: Air heat source heat pump evaporator (outdoor side heat exchanger) hot air flow defrosting

[0040] See Figure 4 , Figure 4 It is a schematic diagram of an air heat source heat pump type cooling and heating fan. The figure includes: evaporator (outdoor side heat exchanger) 401, outdoor side fan 402, compressor 403, indoor side fan 404, indoor side heat exchanger 405, fresh air outlet 406, Four-way valve 407.

[0041] Using the method of the present invention to automatically determine the start time of defrosting, a wind speed sensor 101 is installed at the inlet position a of the evaporator 401. When the air source heat pump unit is turned on and enters the cooling operation (step S1), the wind speed sensor 101 measures the initial inlet of the evaporator 401 Wind speed A, and set reference values B and C (step S2, B and C can be set to 0.5 times and 0.9 times of A, respectively). During the subsequent cooling operation, the wind speed sensor 101 continuously...

Embodiment 3

[0042] Example 3: Defrosting of the hot air flow of the air cooler evaporator

[0043] See Figure 5 , Figure 5 It is a schematic diagram of the position of the air cooler evaporator. The figure includes: evaporator 501, liquid supply solenoid valve 502, return air solenoid valve 503, defrost solenoid valve 504, one-way valve 505, liquid supply pipe 506, air return pipe 507, defrost Hot air pipe 508, fan 509.

[0044] Using the method of the present invention to automatically determine the start time of defrosting, a wind speed sensor 101 is installed at the entrance position a of the evaporator 501. When the air cooler is turned on and enters cooling operation (step S1), the wind speed sensor 101 measures the initial wind speed A at the entrance of the evaporator 501 , And set reference values B and C (step S2, B and C can be set to 0.55 times and 0.95 times of A, respectively). In the subsequent cooling operation, the wind speed sensor 101 continuously detects the wind speed at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com