Automatic calibrating system for heat meter

A heat meter and heating water tank technology, which is applied in the field of heat meter automatic verification system, can solve the problems of complex overall structure of the verification device, large temperature correction error, long operation time, etc., achieve fast data collection and processing functions, and reduce flow fluctuations Influence, Accurate Acquisition of Measured Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

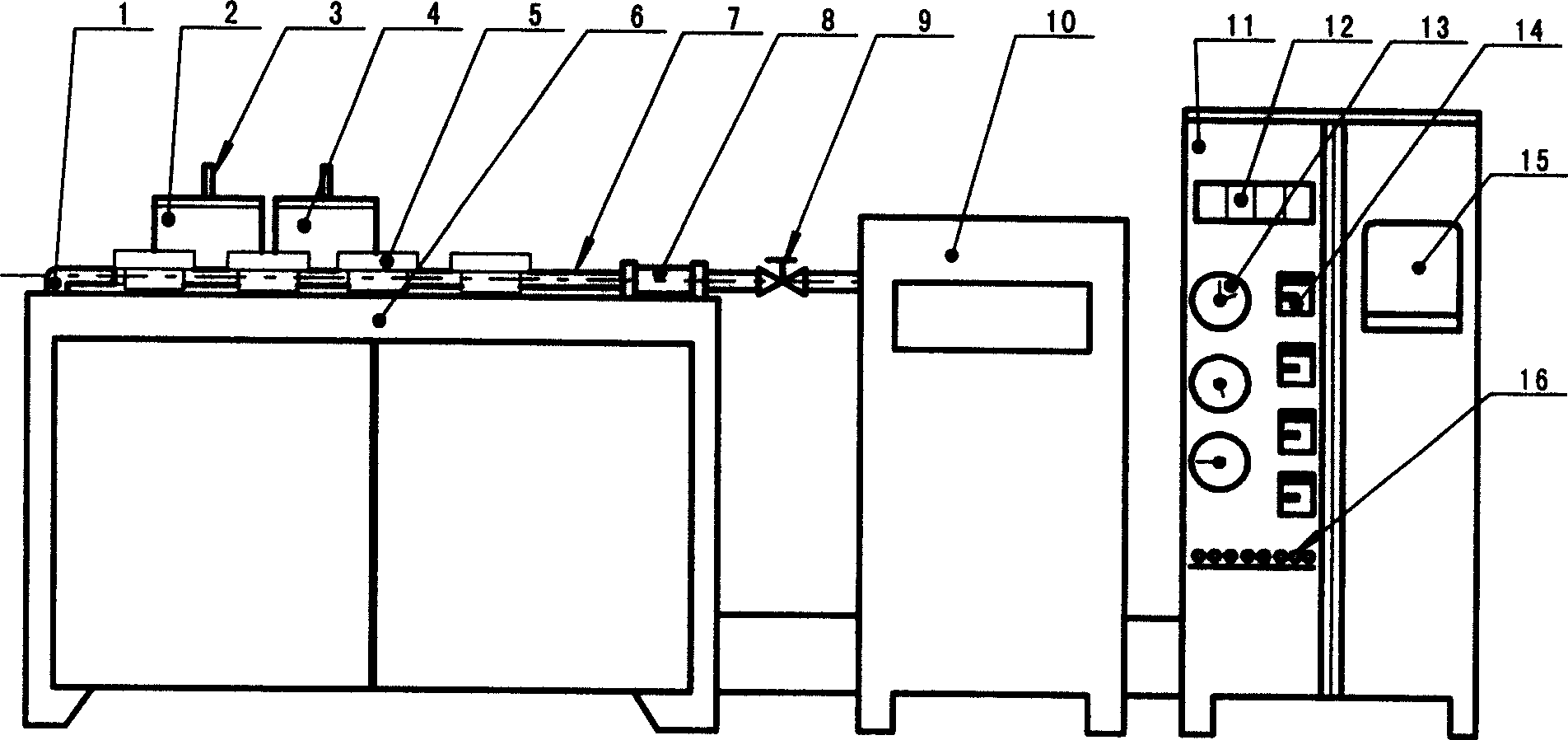

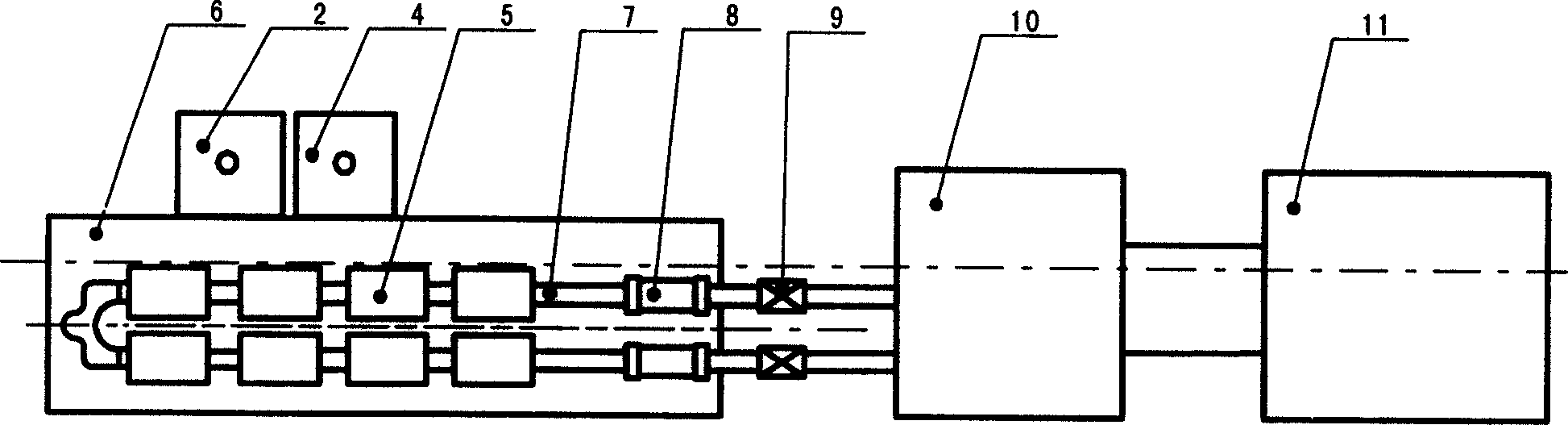

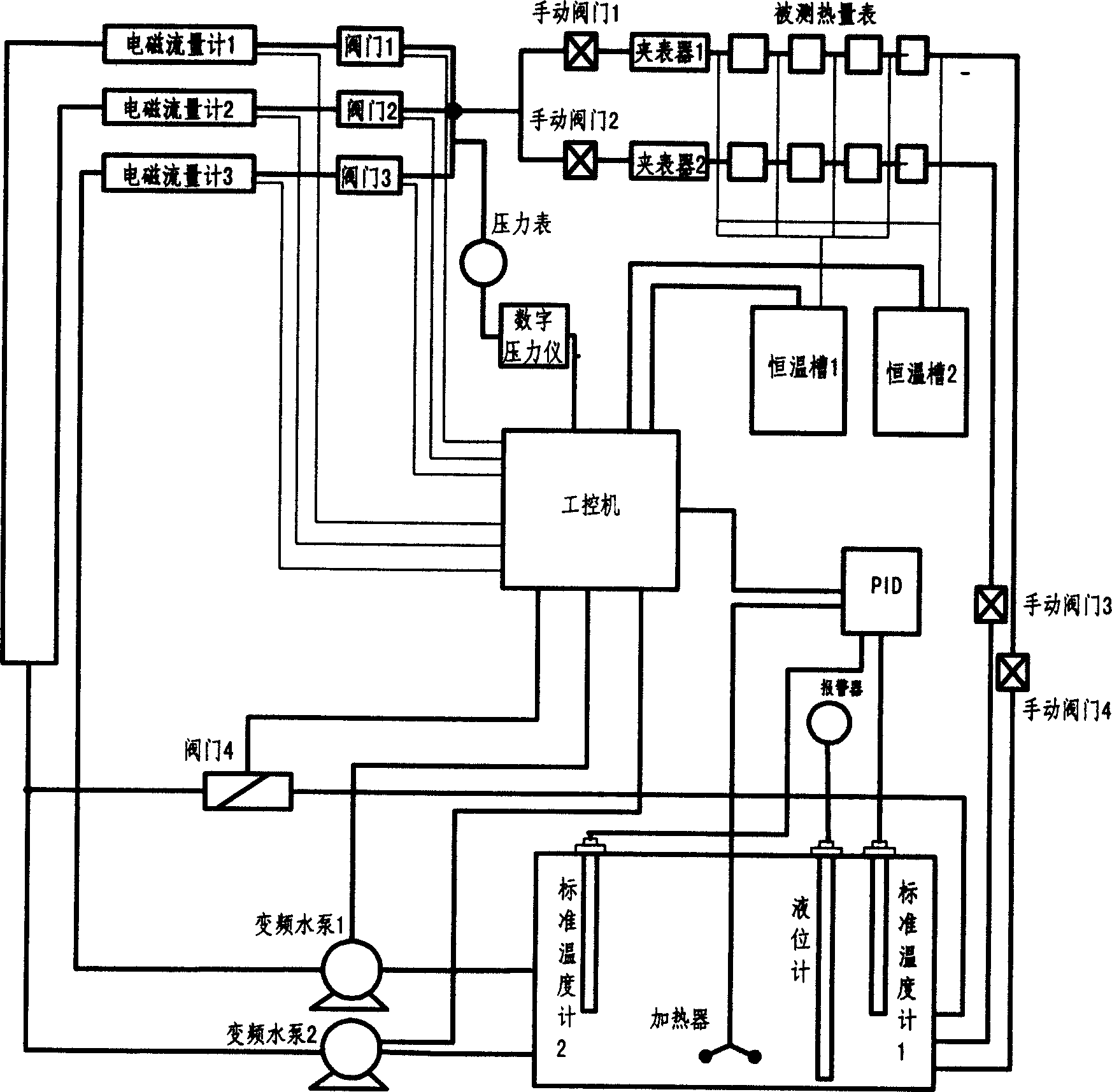

[0020] see figure 1 , figure 2 , the heat meter automatic verification system involved in the present invention is composed of a heating water tank (in the workbench 6), a frequency conversion water pump (in the water pump box 10), a pipeline 7, a water inlet pipeline 1, a constant temperature tank 2, a constant temperature tank 4, The control cabinet 11, the pneumatic meter clamp 8 on the workbench, and the measured heat meter 5 installed on the pipeline of the pneumatic meter clamp (multiple measured heat meters and the pipelines connected to them are also called test pipelines) constitute , a manual ball valve 9 is installed on the pipeline between the pneumatic meter clamp and the water pump. There are two test pipelines on the workbench, and correspondingly, there are two pneumatic meter clamps and manual ball valves. There are two thermos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com