Preparation of (poly) isocyanic ester in gas phase

A technology of steam and air flow, which is applied in the field of continuous preparation of isocyanate, can solve the problems of unsatisfactory service life of the reactor, etc., and achieve the effects of increasing relative yield, reducing residence time, and reducing heat load of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

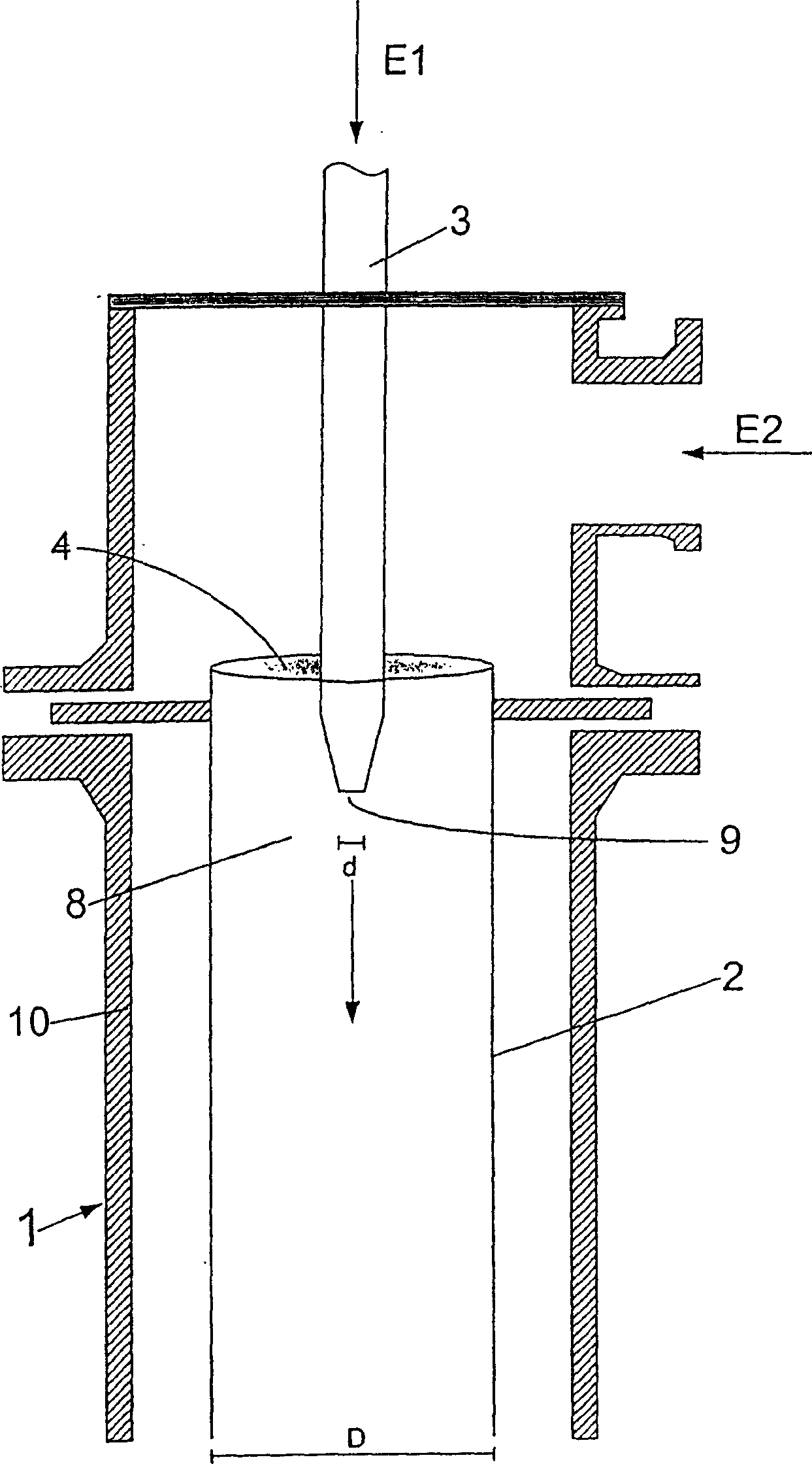

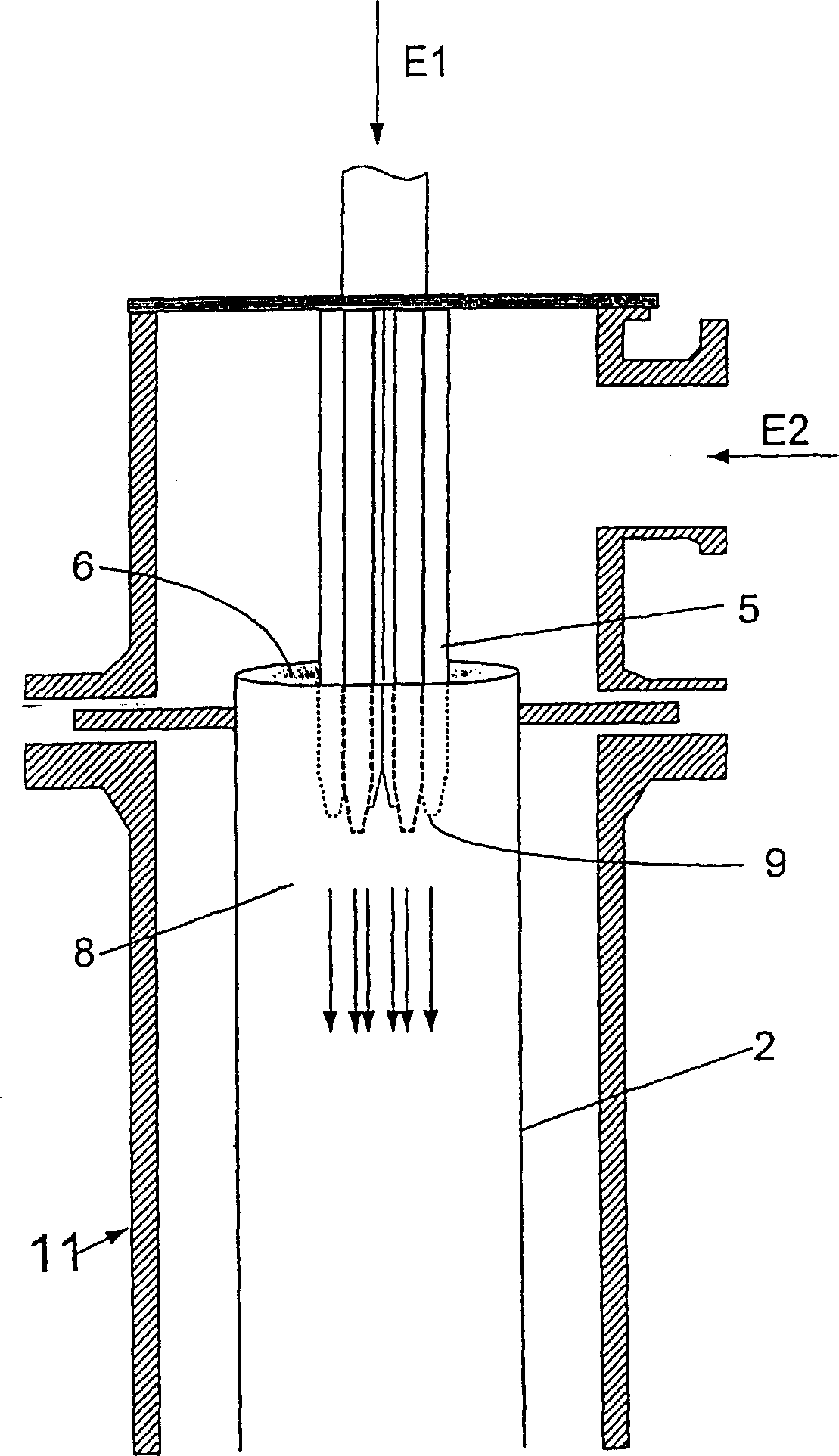

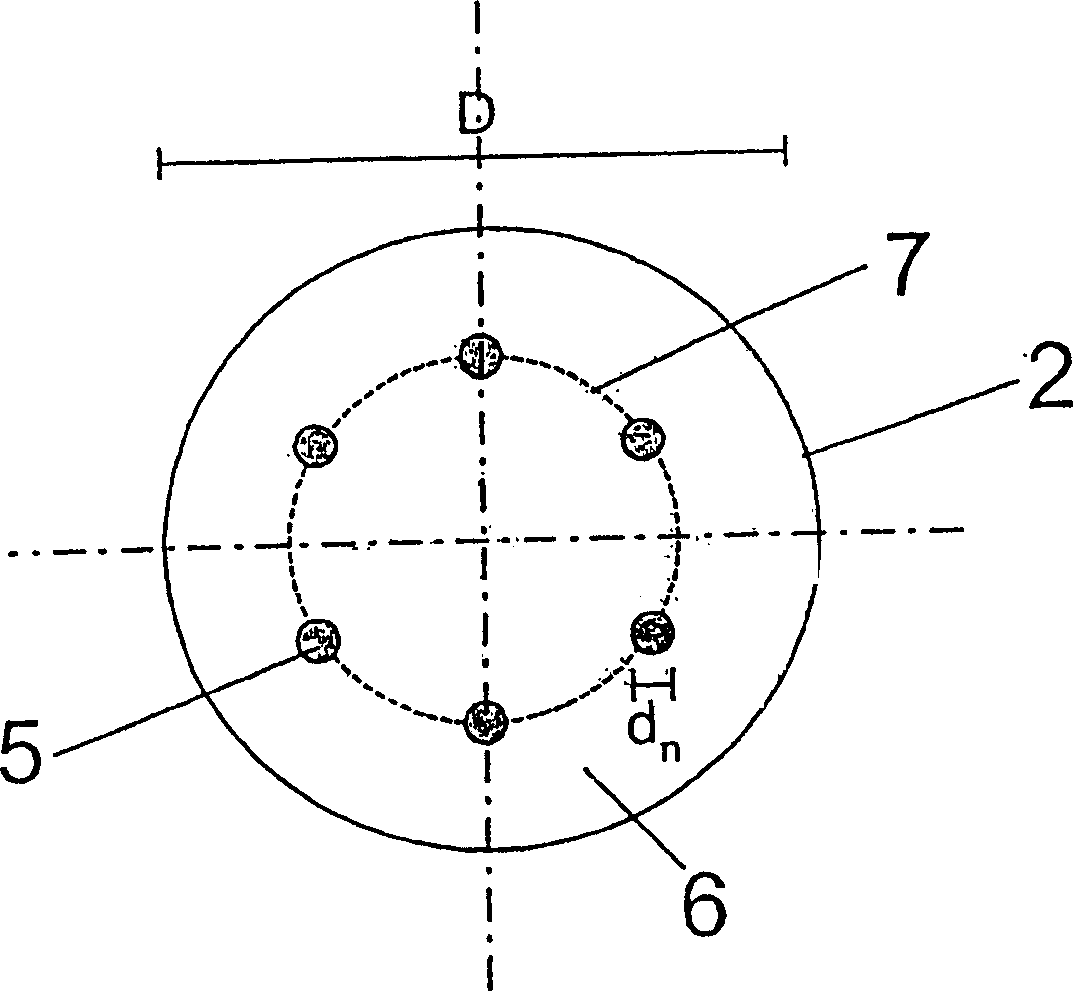

[0046] exist figure 2 The preparation of isocyanate is carried out in the combined mixing reaction tube 2 shown, followed by the isocyanate condensation step, through the multi-nozzle with 6 independent nozzles 5, 2,4-toluenediamine / 2 with a molar ratio of 1:6:0.2 is continuously added, The isomer mixture (TDA80 / 20) of 6-toluenediamine, phosgene and nitrogen, the above-mentioned nozzles are arranged in a ring shape, all extend into the reaction tube 2 . Each educt was evaporated separately in pure form and heated to 340-370° C. in a preheat exchange step. The mixture (E1) of nitrogen and TDA flows in through six separate nozzles 5 arranged in a ring shape, and the phosgene (E2) flows in from the remaining space 6 around the independent nozzles 5 . The ratio of the cross-sectional area of the reaction chamber 8 to the total area of the six independent nozzles 5 is 192:1 (as in Comparative Example 1). The pressure in the reaction zone was 1.5 bar. After passing through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com