Measuring method for precision parallelism

A measurement method and parallelism technology, applied in the measurement field, can solve problems such as limiting IC processing accuracy, and achieve the effects of improving processing level and integration, easy operation, and high adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

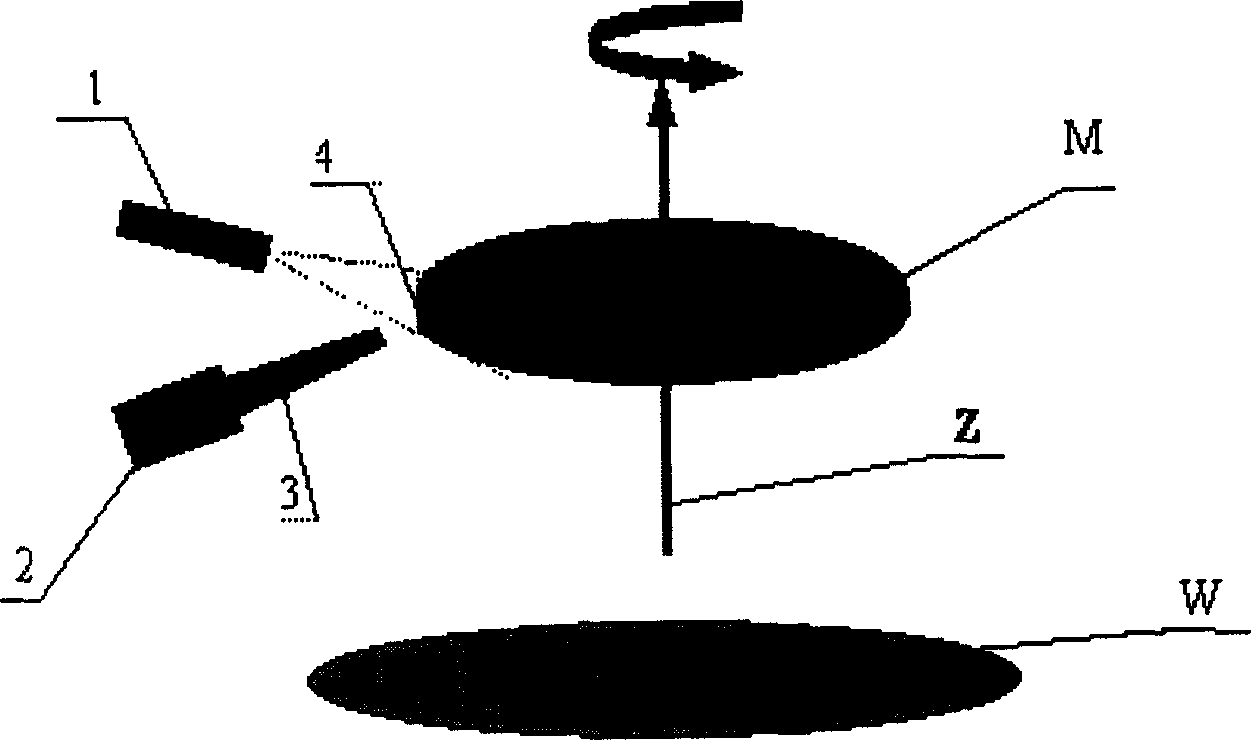

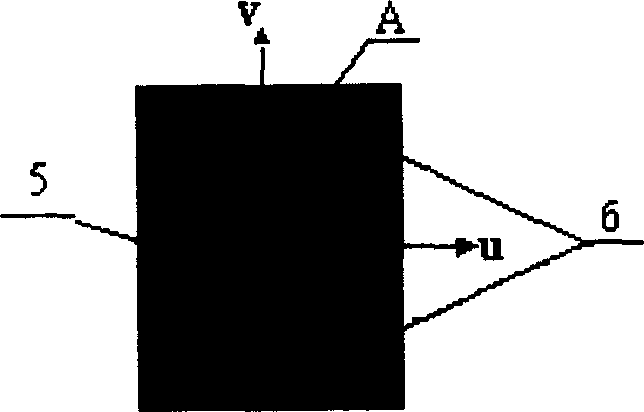

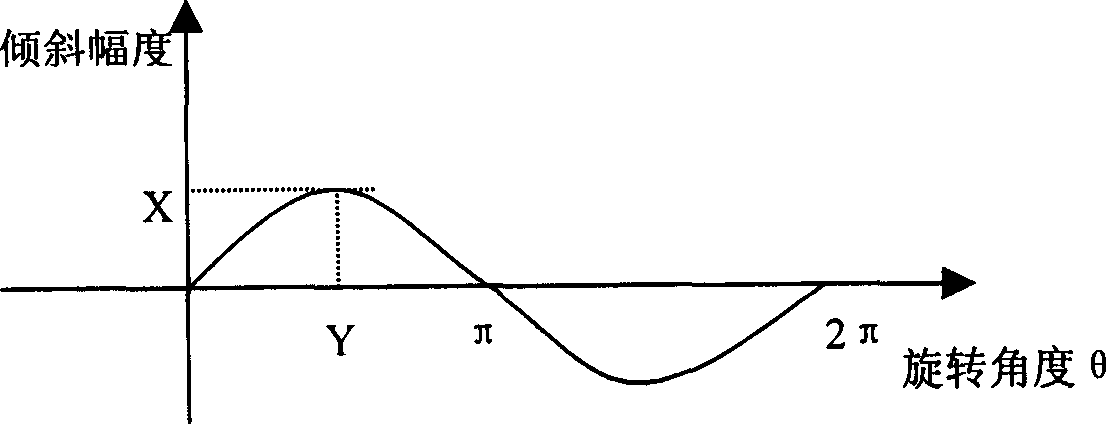

[0014] Suppose M is the object to be measured, W is the reference plane, which is located below the reference plane W, and Z is the rotation axis. The object M to be measured is installed on a platform with a rotation axis Z, which can rotate around the rotation axis Z. The rotation axis Z and The reference plane W is vertical; a bundle of illumination sources and a camera (a CCD camera is used in this embodiment) are used as the measuring device, so that the camera lens is aimed at the side of the object M to be measured, and the light source projected on the side of the object M to be received Reflective imaging, that is, the reflected light imaging projected on the side of the measured object is generated on the camera; the horizontal axis u and the vertical axis v are the image coordinate system after imaging, and the origin is at the center of the imaged image, where the measured object M lower plane The intersection point A with its side crossing the vertical axis v is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com