Variator air valve device for IC engine

An internal combustion engine, variable technology, applied in the direction of valve devices, non-mechanically actuated valves, mechanical equipment, etc., which can solve the problems of cost-increasing devices, increased power consumption, and insufficient fuel consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

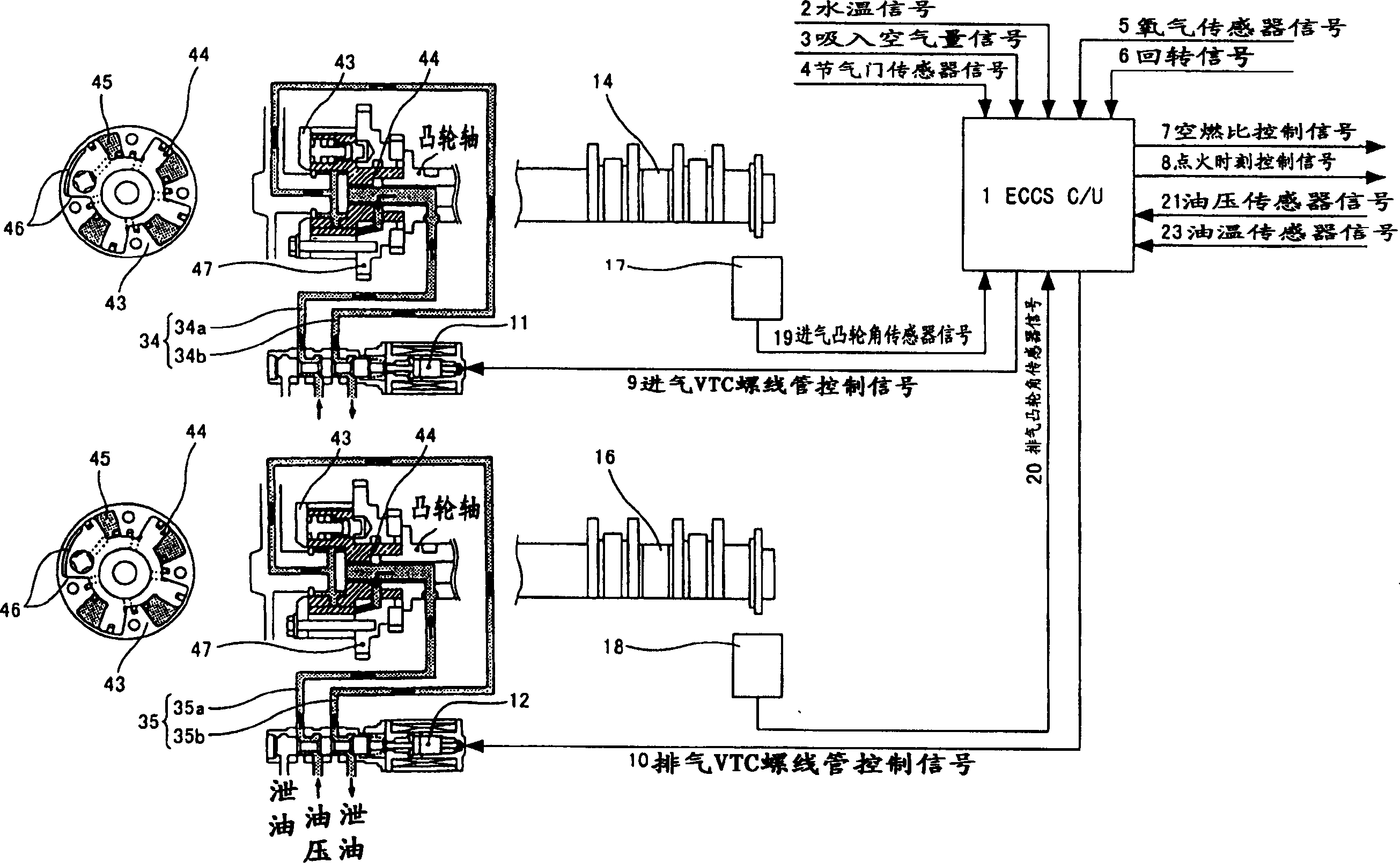

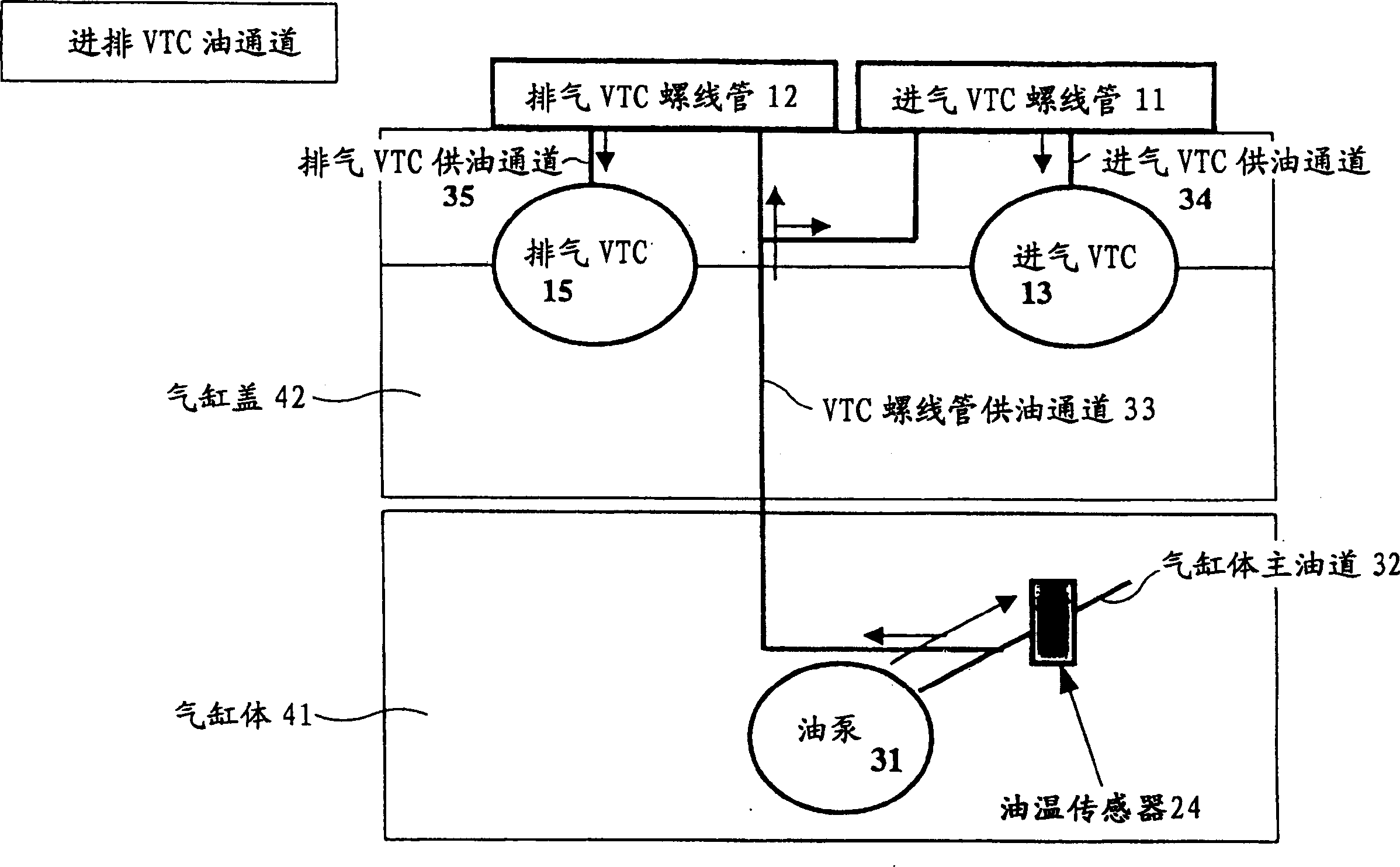

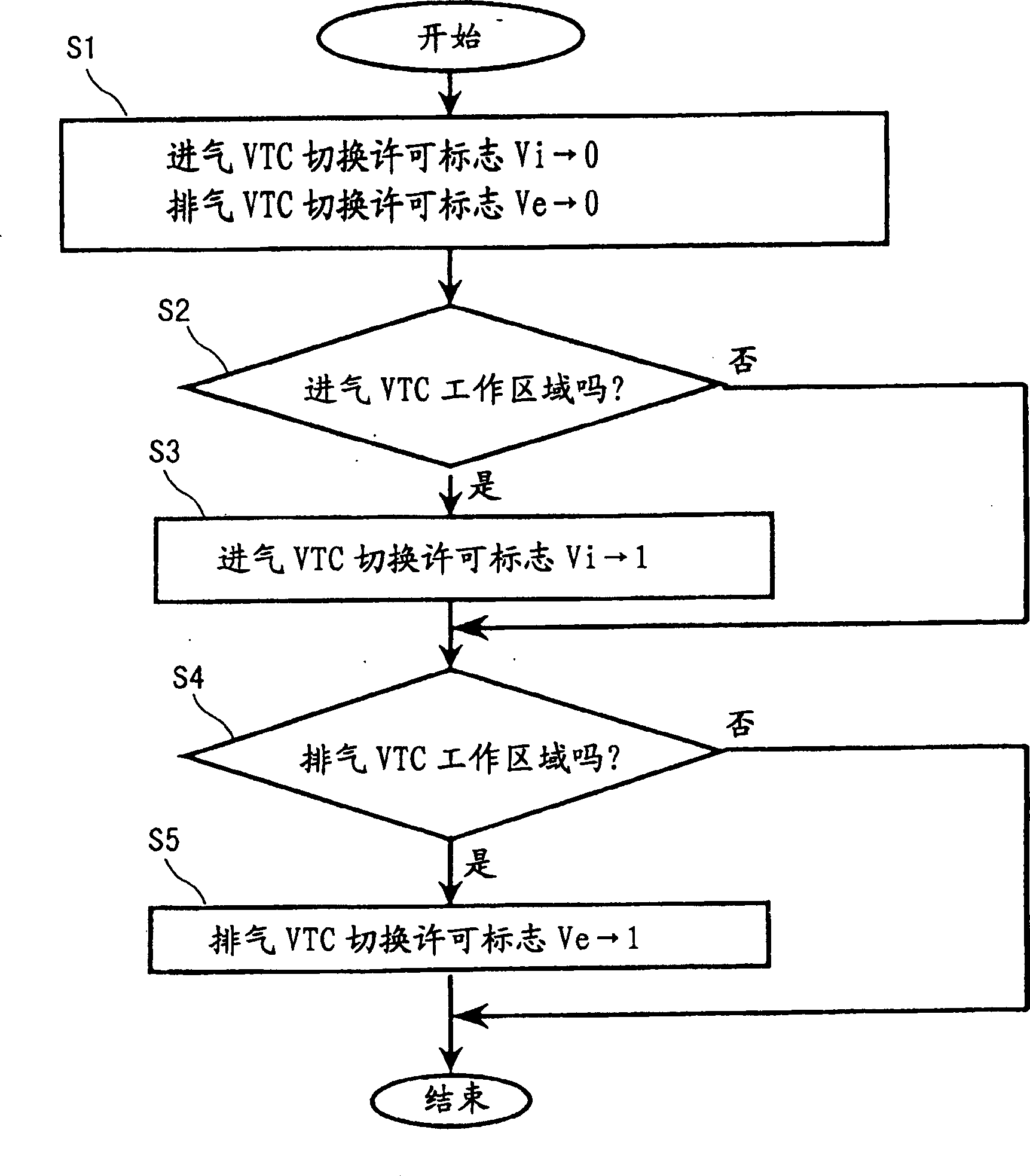

[0020] The preferred embodiments of the present invention will be described in detail below based on the drawings. in figure 1 Among them, the intake-side variable valve timing mechanism (hereinafter referred to as intake VTC) 13 as the intake-side variable valve mechanism can continuously change the valve timing of the intake valve as the exhaust side of the exhaust-side variable valve mechanism. The air-side variable valve timing mechanism (hereinafter referred to as exhaust VTC) 15 can continuously change the valve timing of the exhaust valve. These VTC (Valve Timing Controls) themselves are known technologies as disclosed in the above-mentioned Japanese Patent Application Laid-Open No. 2002-161721, and are briefly described here.

[0021] Each VTC has a housing 43 fixed to a cam sprocket 47 that rotates in conjunction with the crankshaft, and vanes 44 housed in the housing 43 and fixed to the intake camshaft 14 or the exhaust camshaft 16. Between the vane 44 and the casing 43...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com