Open wafer box before prevetion of outgassing pollution and method for preventing outgassing pollution

A front-opening wafer box, wafer box technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of reducing the yield of products, and achieve the effect of simple application, simple structure and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the above and other purposes, features, and advantages of the present invention more comprehensible, a preferred embodiment is specifically cited below, together with the accompanying drawings, as follows:

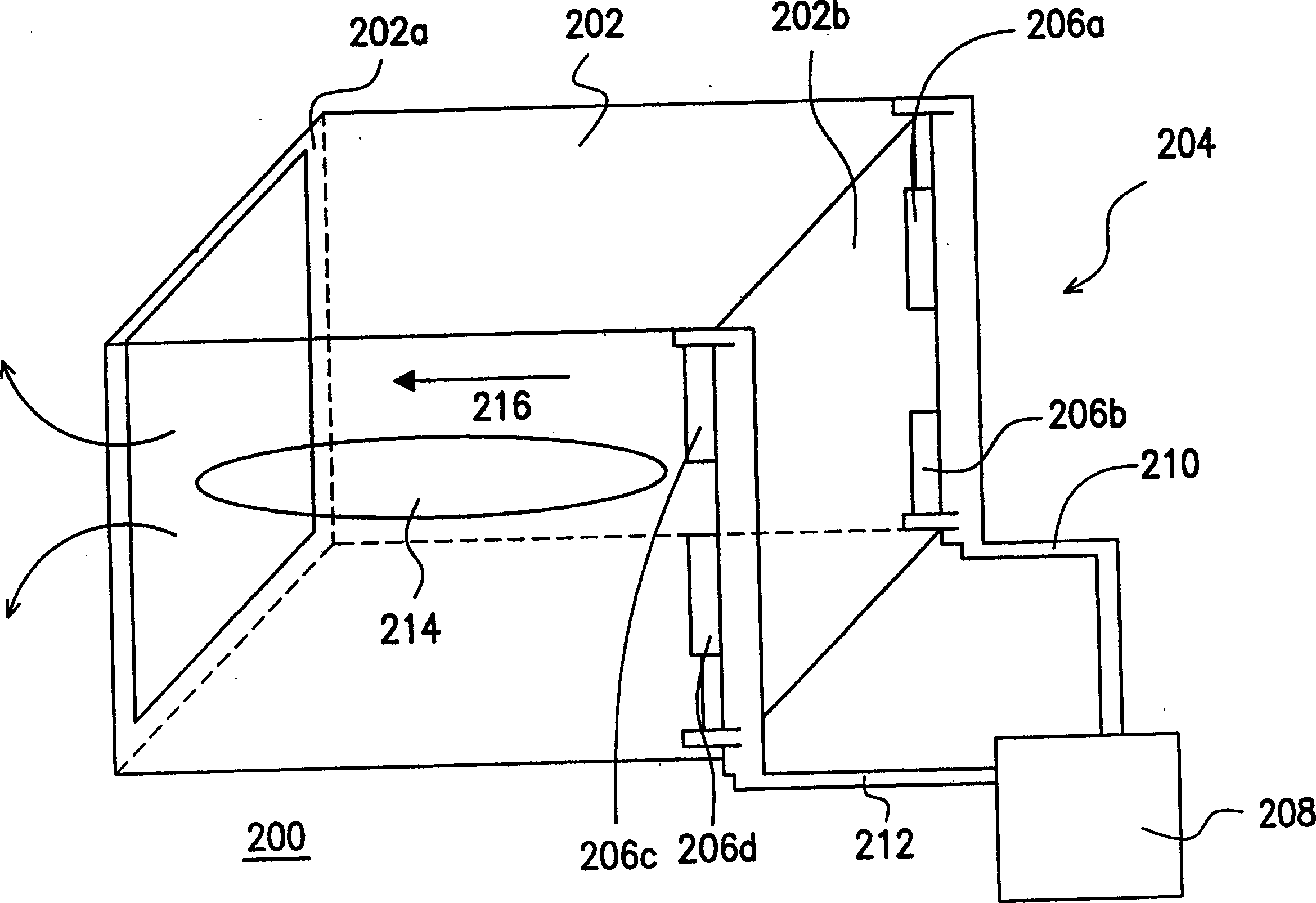

[0019] figure 2 It is a schematic diagram showing the three-dimensional structure of the front opening wafer cassette of the present invention.

[0020] Please refer to figure 2 As shown, the FOUP 200 of the present invention includes a FOUP body 202 and a cleaning device 204 . The cleaning device 204 is constituted by, for example, blowing members 206 a to 206 d , a gas supply device 208 , and pipes 210 and 212 .

[0021] The air blowing members 206a-206d are arranged inside the FOUP body 202, and a plurality of air blowing members 206a-206d are arranged at the opening of the FOUP body 202 in a staggered manner, for example, at intervals. 202a is opposite to the left and right sides of the bottom plate 202b. For example, the blowing component...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com