AC stepless variable power automatic speed-regulating motor

A self-speed-adjusting and power-changing technology, applied in the field of AC stepless variable-power self-speed-adjusting motors, can solve the problems of electromagnetic speed-adjusting motors, polluting motors, polluting power grids, etc., and save starting equipment, electricity, and investment. and lower maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

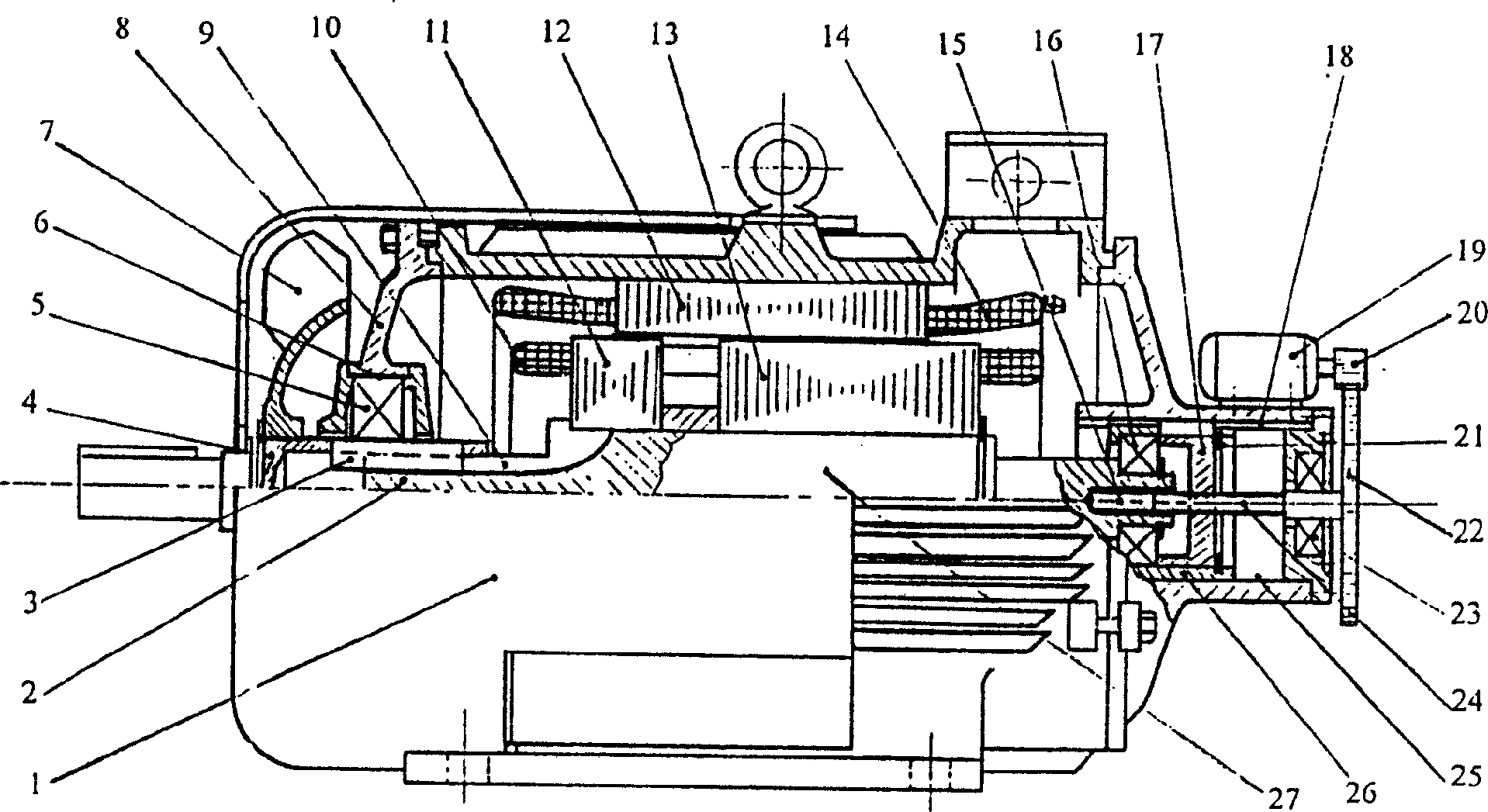

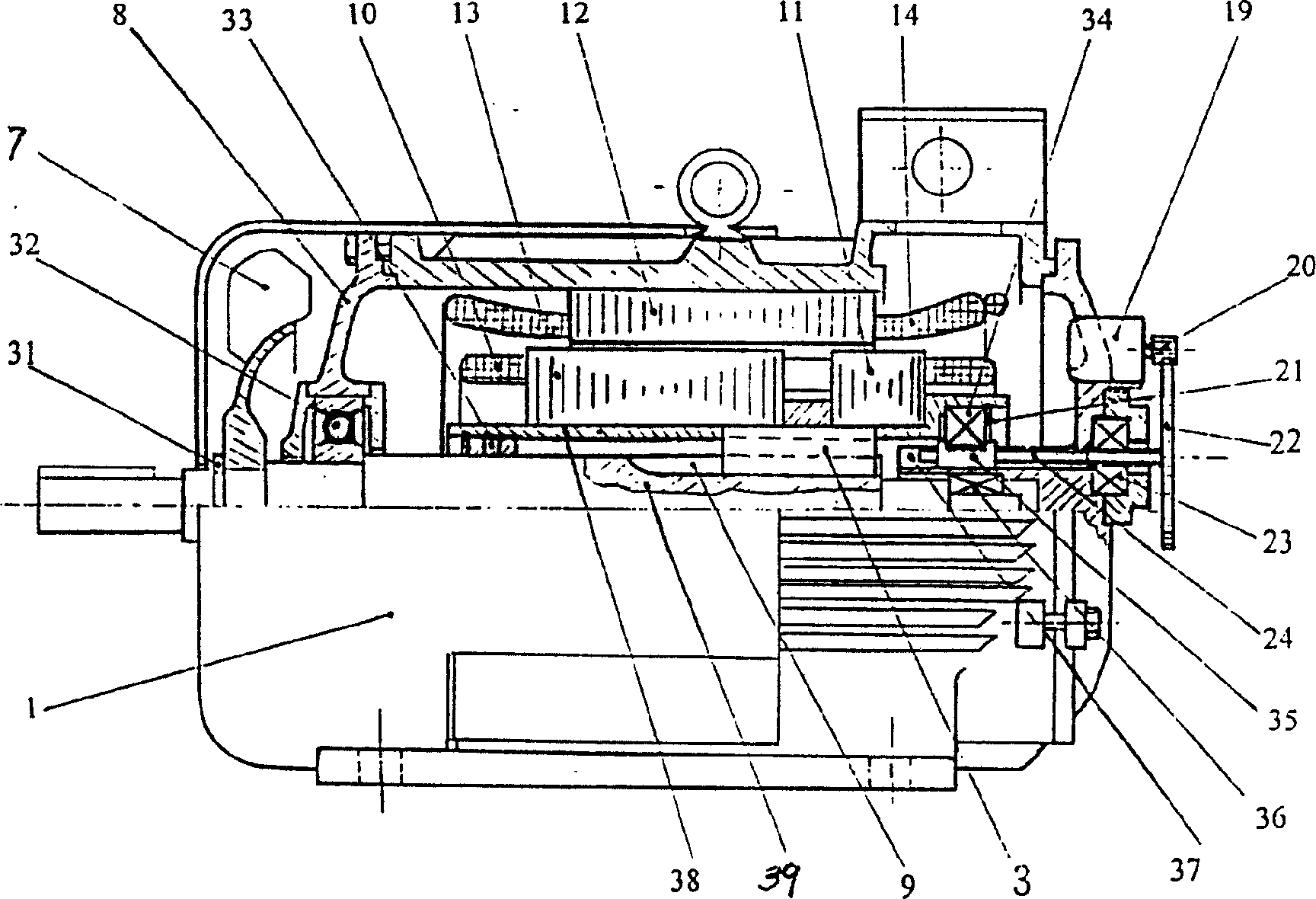

[0029] exist figure 1 In the shown embodiment, the three-phase stator winding (14) is embedded in the stator slot of the stator core (12) and dipped in insulating varnish; the rotor short core (11) with 36 slots, the spacer ring between the two sections of the core, the 36-slot The long rotor core (13) of the figure 1 The positions are sequentially pressed on the rotor shaft (27), and the iron core positioning collar is installed and finished; the insulated self-short-circuit coil shared by the long and short iron cores is wound, and the long and short-circuited coils with the grooved insulating layer are embedded with 1 / 2 pole pitch. In the iron core slot, and between the two sections of the iron core, the electrical angle of 180 degrees is reversed and the pitch is changed, and then the rotor winding (10) is formed by embedding the full pitch in the short iron core slot with the slotted insulating layer, and the winding (10) The two ends and the anti-phase section in the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com