Method for fabricating anti-reflection film and structure of film

A technology of light-enhancing film and manufacturing method, which is applied in the fields of optics, nonlinear optics, instruments, etc., and can solve problems such as complicated procedures and technologies, complicated manufacturing processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

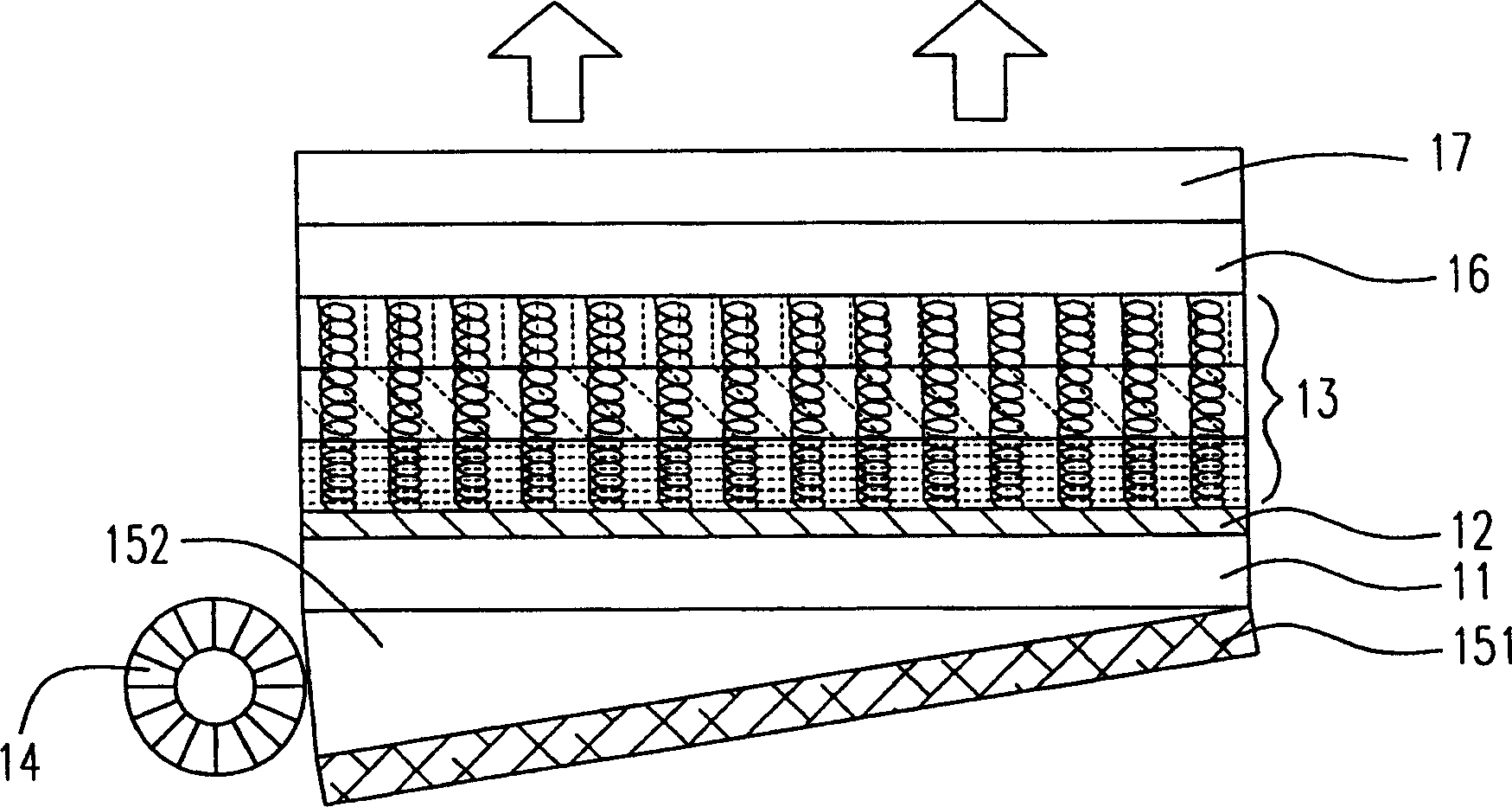

[0063] The main purpose of the present invention is to provide a method for quickly and easily producing the multi-layer cholesteric liquid crystal film, that is, the brightness enhancement film.

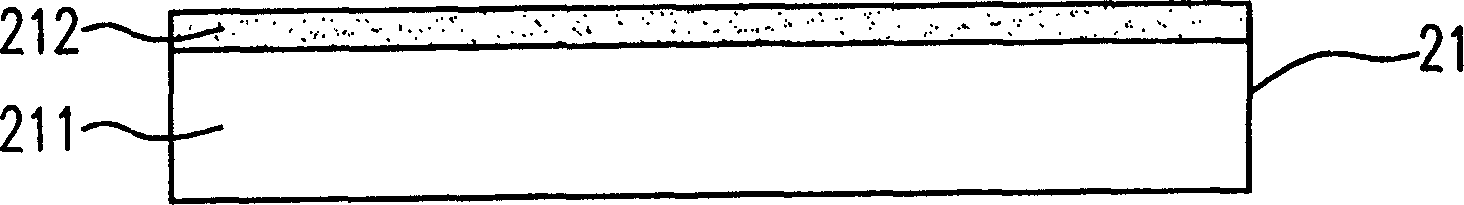

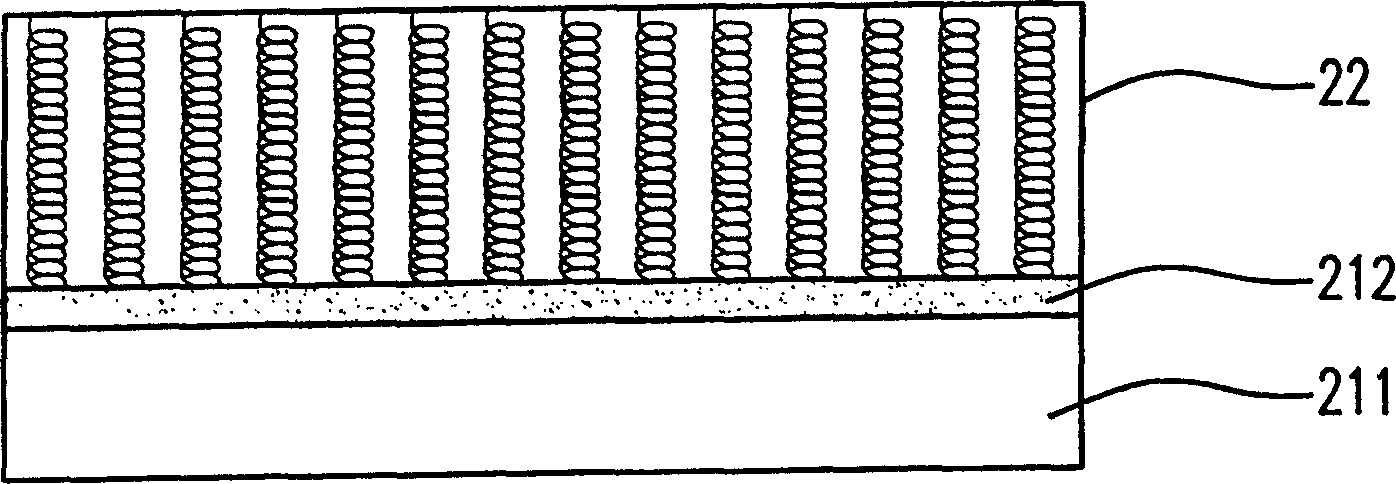

[0064] Please refer to FIG. 2 , the manufacturing method of the light enhancing film of the present invention includes the following steps: (1) providing a first substrate 21, as shown in FIG. 2( a); (2) by a coating method, Form a first polymer liquid crystal layer 22 on the first substrate 21, as shown in FIG. This first polymer liquid crystal layer 22 of the first substrate, to form a first light-transmitting layer 221, as shown in Figure 2 (c); (4) provide a second substrate 23, as shown in Figure 2 (d) (5) form a second polymer liquid crystal layer 24 on the second substrate 23 by coating (coating), as shown in FIG. 2( e); (6) through the second substrate 23, And by UV curing (UVcuring) part of the second high-resolution liquid crystal layer 24 close to the second substrate 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com