Surface-mounting high frequency modular

A surface-mounted, high-frequency module technology, applied in high-frequency matching devices, circuit devices, printed circuits, etc., can solve problems that hinder the miniaturization of high-frequency modules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

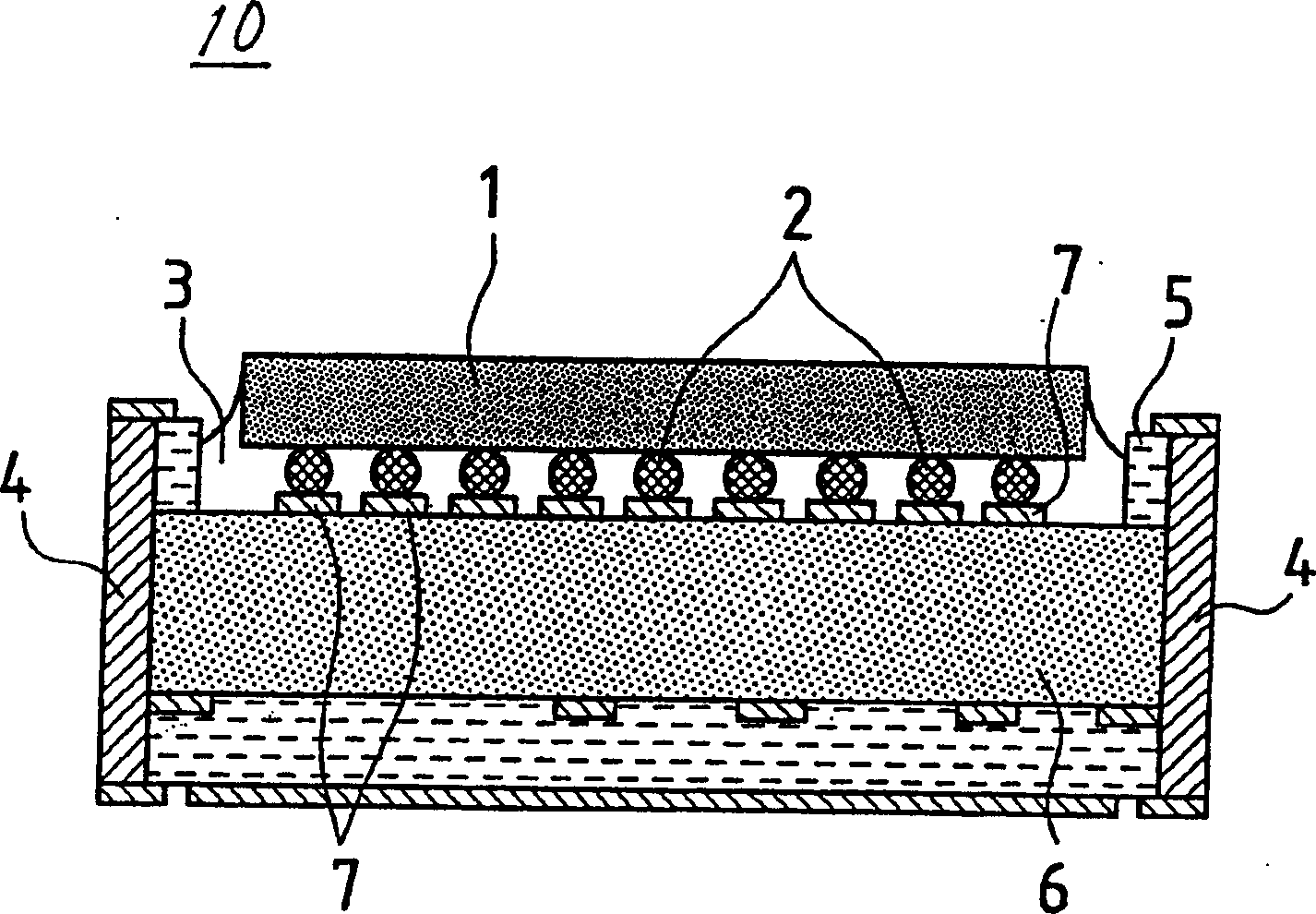

[0029] figure 1 Shown is a cross-sectional view of the surface-mounted high-frequency module 10 of the present invention.

[0030] The surface-mounted high-frequency module 10 of this embodiment is such as figure 1 Shown is a multilayer substrate with a BGA package IC1 and a printed circuit board on which the BGA package IC1 is mounted, and a multilayer substrate in which an inner layer composed of a core material 6 and an outer layer composed of a combination layer 5 constituting the outer layer of the inner layer are laminated as the Surface mount high frequency module of printed circuit board. In addition, the upper surface of the printed circuit board (core material 6) on which the mounting portion of the BGA package IC1 is mounted is formed lower than the upper surface of the outer layer (combined layer 5).

[0031] In addition, a soldering pad 7 for electrically conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com