Method for utilizing aluminium cinder as resource

A technology of aluminum slag ash and recycling, which is applied in the field of ceramic filter materials and can solve problems such as the inability to regenerate waste resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] refer to figure 1 , the basic steps of the present invention are:

[0029] a, using aluminum slag ash as raw material;

[0030] b. Perform high-temperature calcination and stabilization;

[0031] c. Raw materials for making refractory materials.

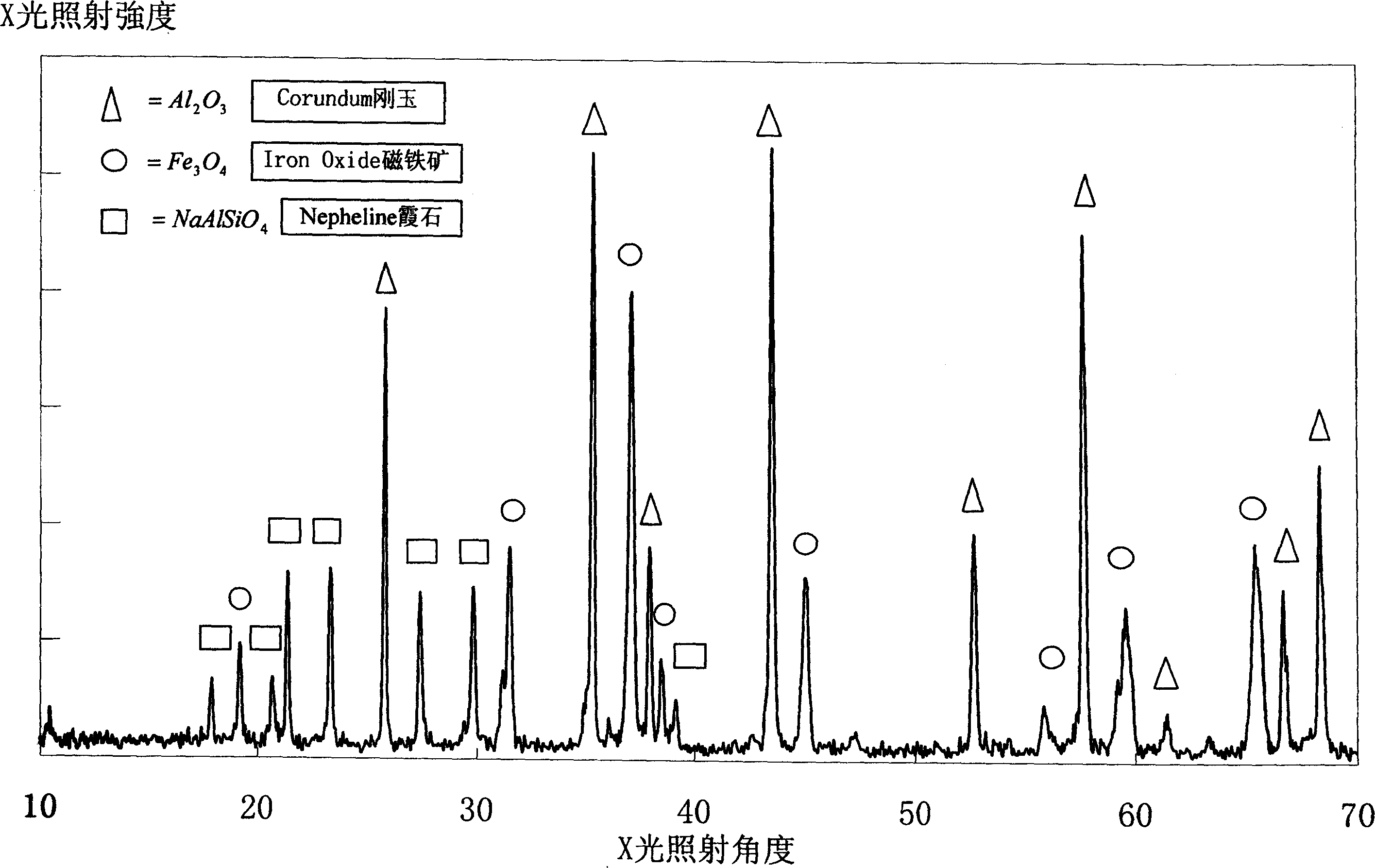

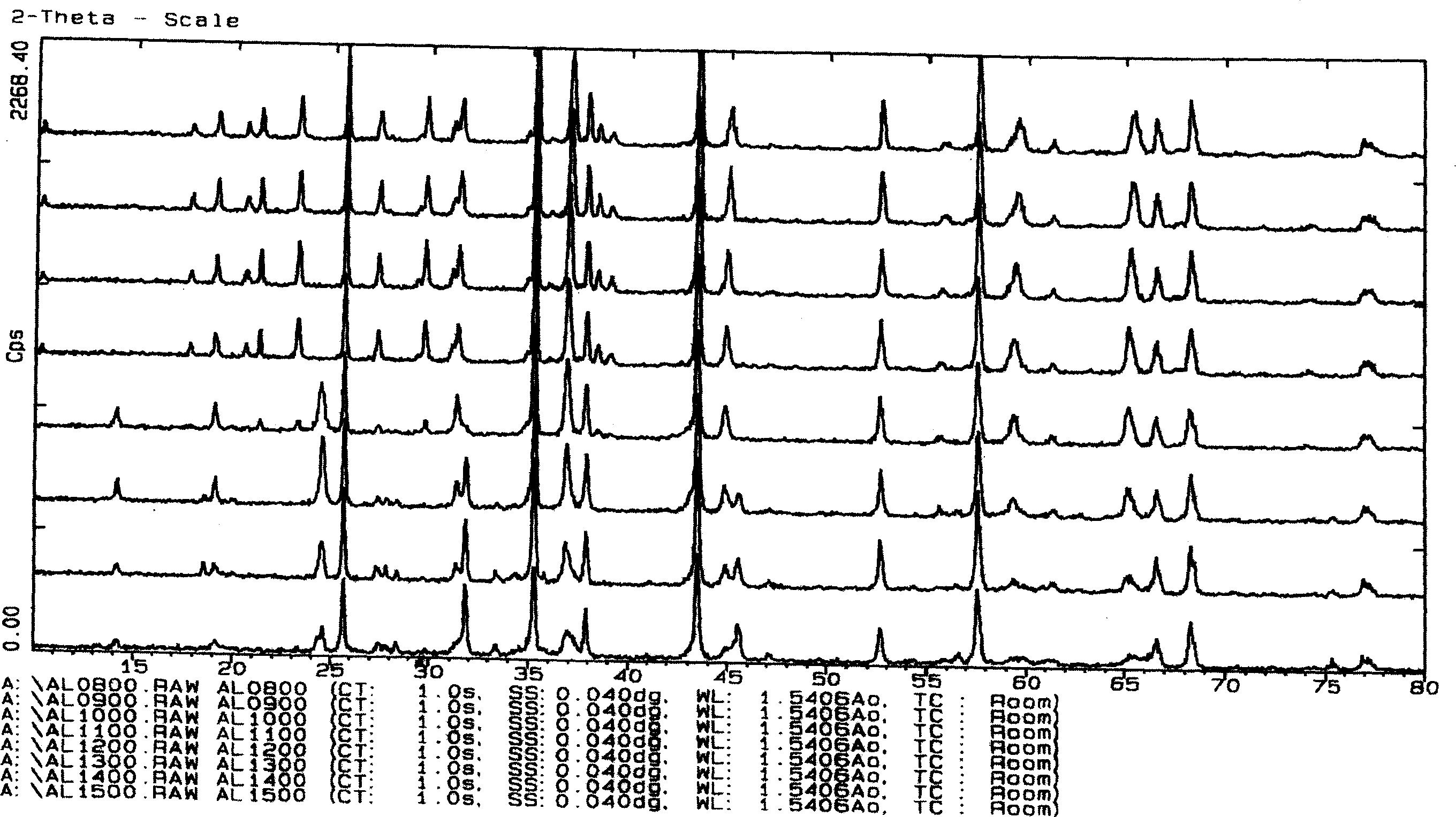

[0032] In the above steps, the aluminum slag ash is mainly calcined at high temperature in a high-temperature kiln (Calcination) to transform it into a material whose main component is alumina (the mineral crystal phase is corundum), which is used as a raw material for refractory materials. In calcination, aluminum nitride (AlN) and aluminum carbide (Al 4 C 3 ) will tend to be stable.

[0033] The aforementioned high-temperature calcination has a temperature range from 800°C to 1800°C.

[0034] The above-mentioned aluminum slag ash refers to the residue after sorting and recovering metal aluminum from aluminum smelting slag or the fine particles obtained from crushing and grinding process of aluminum smelting slag.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com