Installation structure of knockmeter in internal combustion engine

A technology of knock sensor and installation structure, which is applied in the testing of machine/structural components, engine testing, machine/engine, etc. It can solve problems such as limitation of freedom of installation and configuration, reduction of sensor durability, sensor damage, etc., and achieve improvement Reliability and the effect of preventing malfunction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

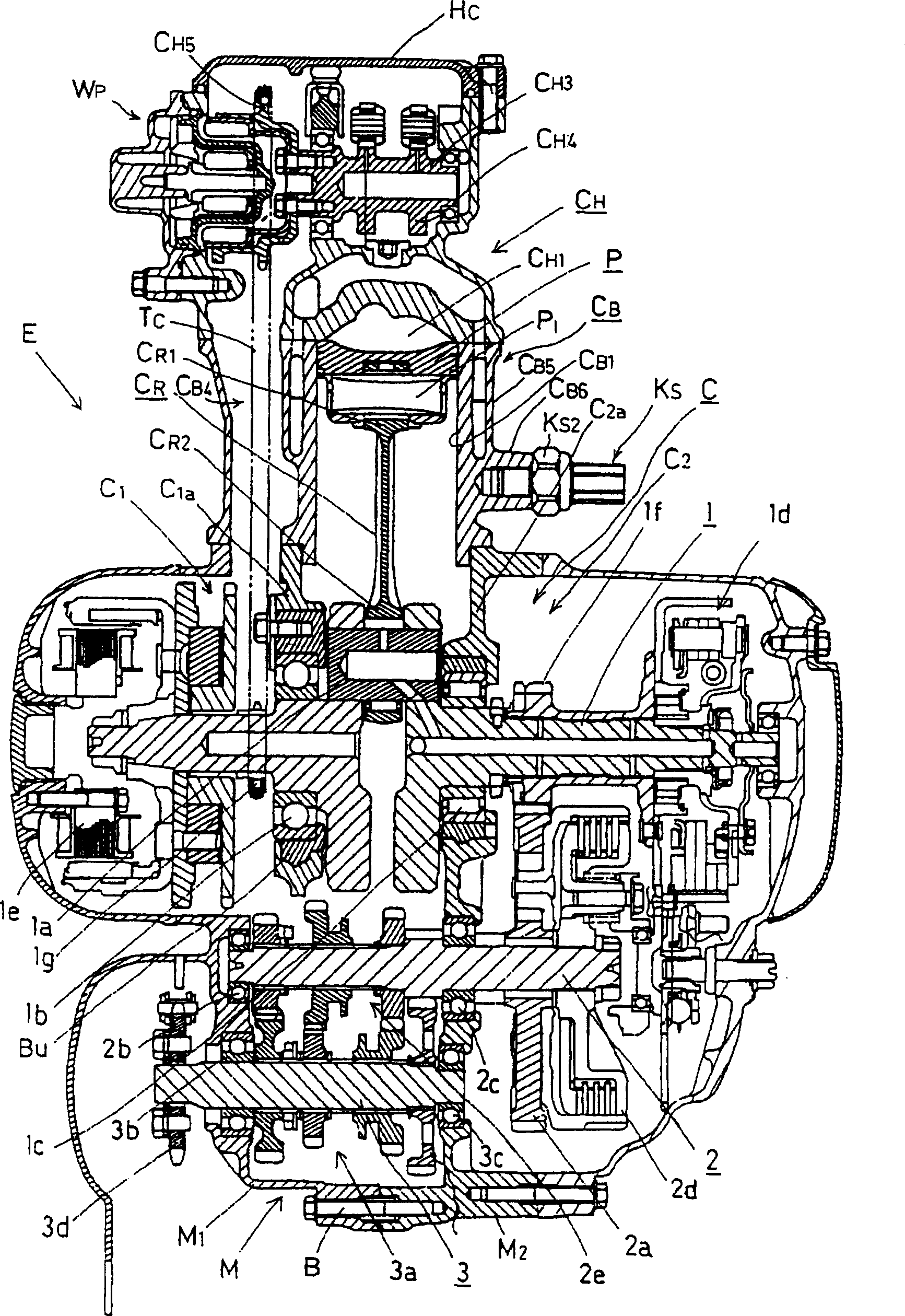

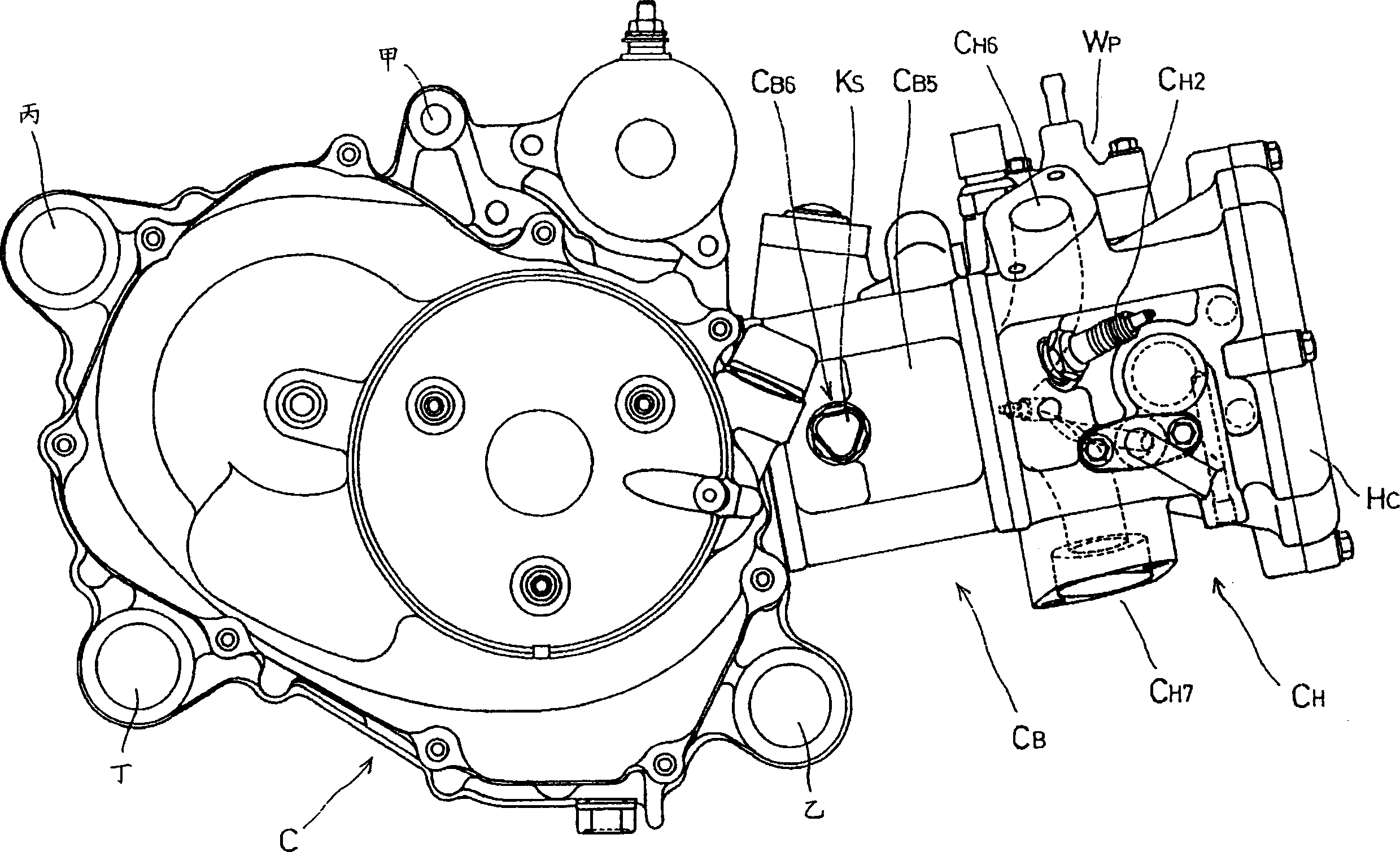

[0029] The following is based on Figure 1 to Figure 6 Embodiments of the present invention will be described.

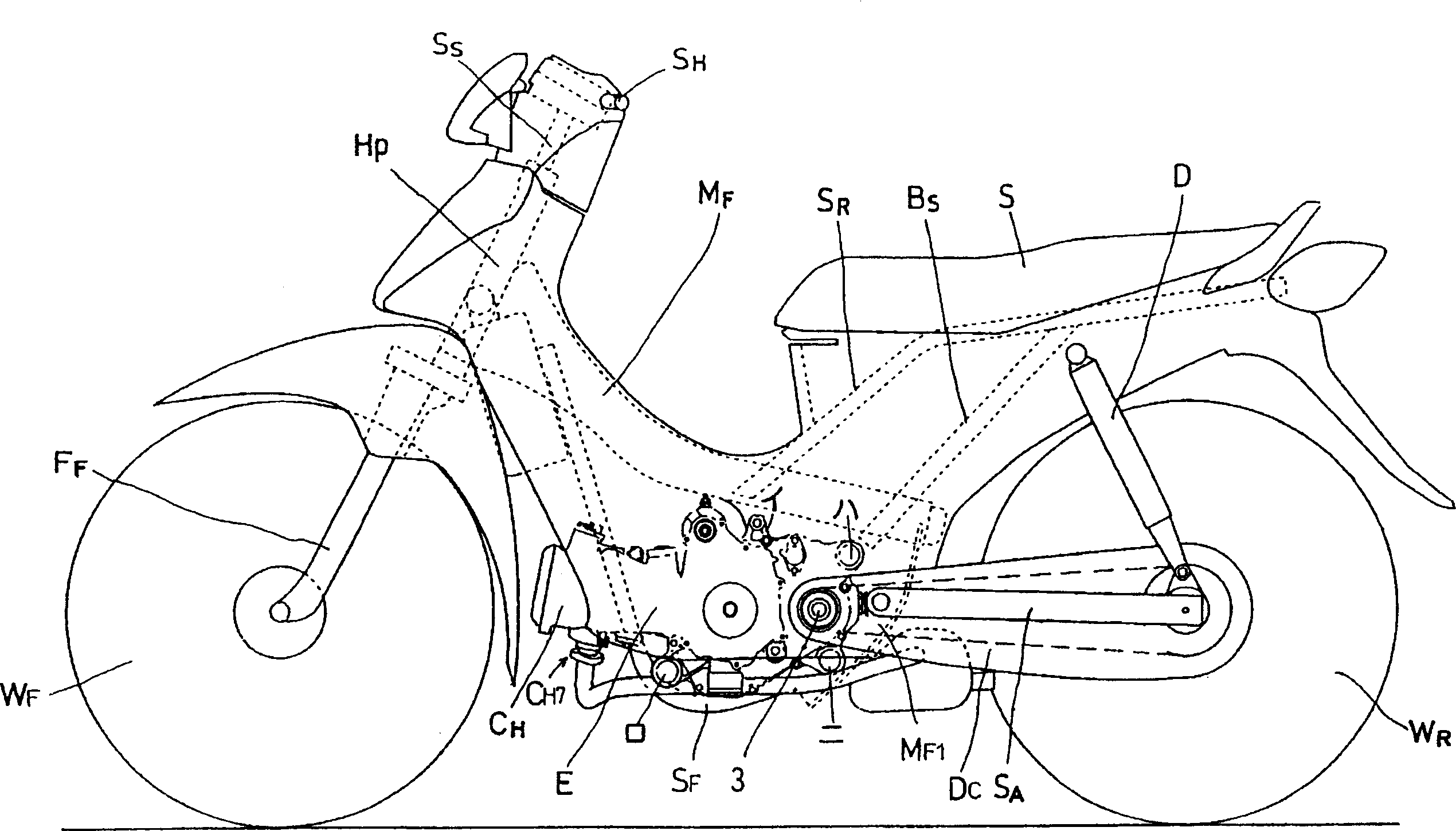

[0030] figure 1 It shows the overall view of the motorized two-wheeled vehicle equipped with the internal combustion engine of the embodiment of the present invention. The motorized two-wheeled vehicle has: the main frame M F ; Front pipe H P , which points slightly towards the main frame M F and installed on its front end; the lower extension of the main frame (internal combustion engine hanger plate) M F1 , which to the main frame M F The lower part of the rear is slightly bent into an arc; the subframe S F , which is connected to the main frame M F The front part of the main frame and the lower extension M of the main frame F1 the lower end of.

[0031] Also available: a pair of seat rails S R , which is mounted on the main frame M F on the bracket set slightly to the middle of the rear, extending to the rear while pointing slightly upward; a pair of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com