Detection equipment of Coriolis mass flow meter

A mass flowmeter and detection device technology, which is applied to mass flow measurement devices, direct mass flowmeters, etc., can solve the problems of limited sensitivity improvement, lack of elastic support mechanism, detection tube leakage, etc., to reduce requirements and improve measurement sensitivity , The effect of production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

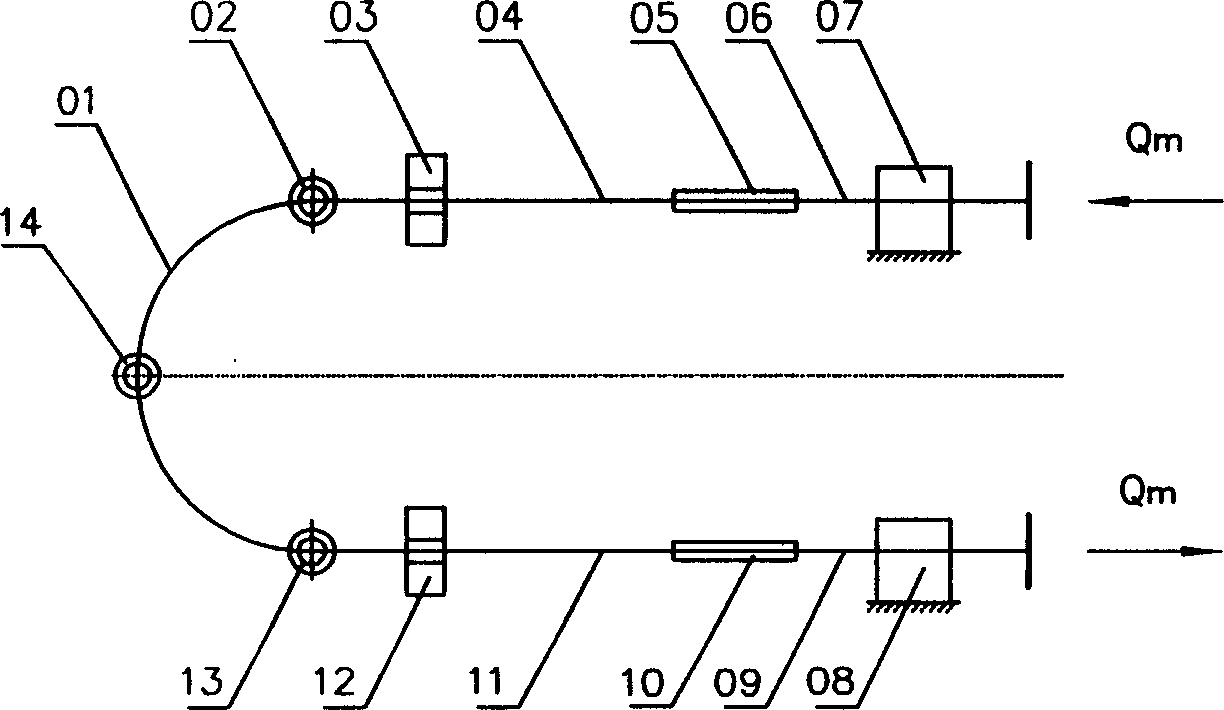

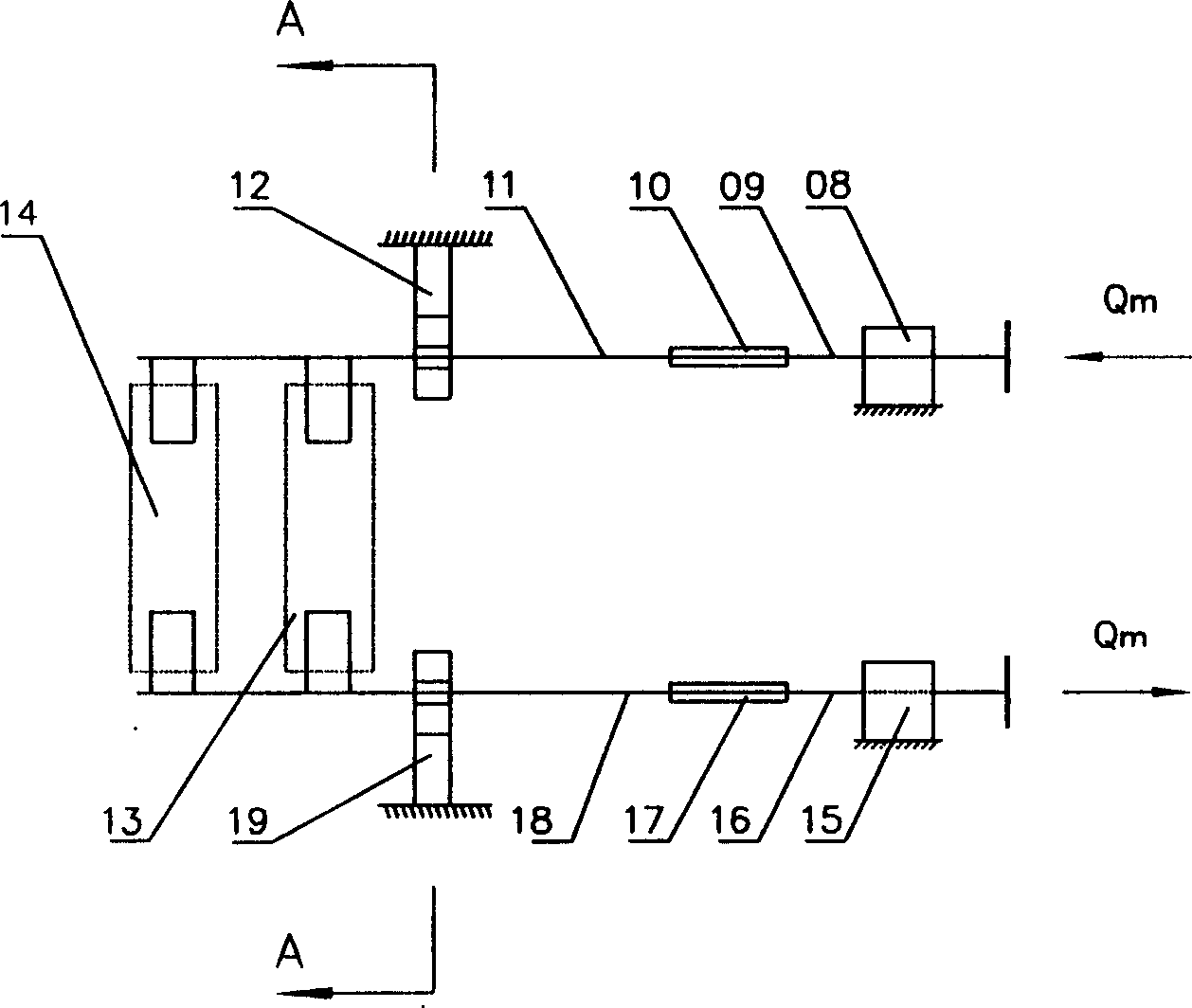

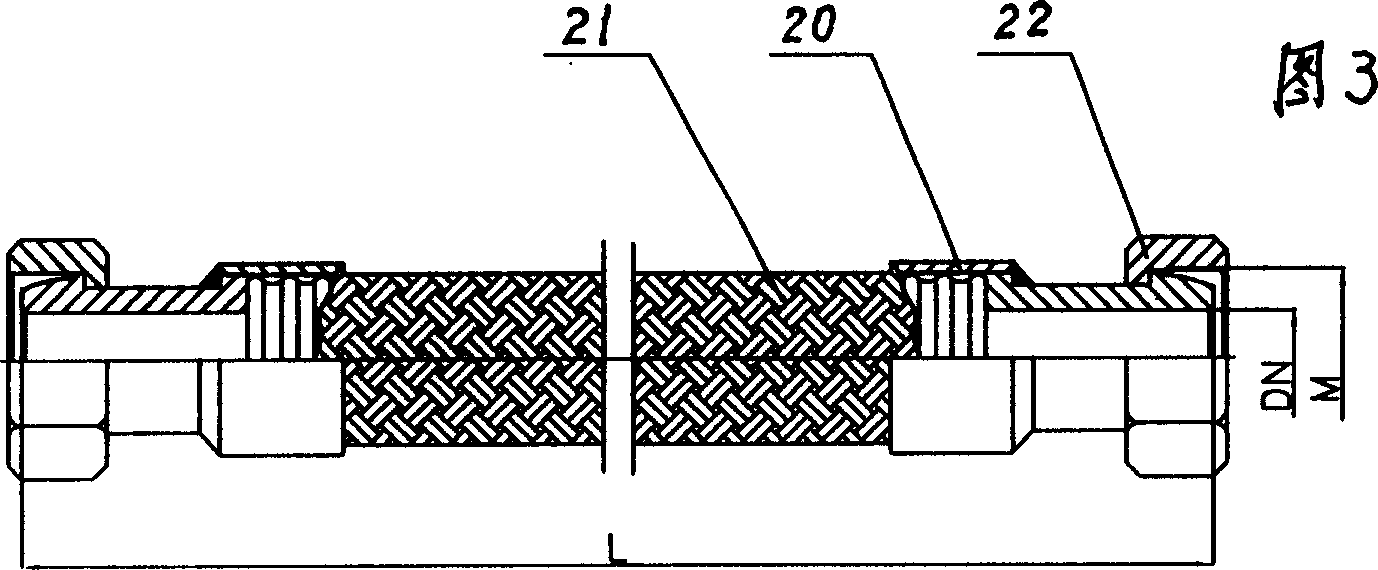

[0028] Combine now figure 1 , figure 2 An embodiment of the present invention is described by taking a double U-shaped tube type detection tube as an example. figure 1 01 is the arc section of the rigid detection tube, 04, 11 is the straight tube section of the rigid detection tube, figure 2 Middle 18 is a side pipe section of the lower U-shaped pipe, and the symmetrical side of the upper U-shaped pipe cannot be drawn. The rigid detection pipe composed of 01, 04, 11 is connected with the process pipe 06, 09 through the metal hose 05, 10, and the metal hose 05, 10 also becomes an effective part of the detection pipe, and the process pipe is installed on the on the base. 03 and 12 are elastic supporting devices designed in conjunction with the flexible deformation of hoses 05 and 10. 14 is an electromagnetic vibrator that drives the vibration of the detection tube, and 02 and 13 are vibration motion sensors to obtain vibration signals. figure 2 Among them, the straight p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com