Super large-scale plastic injection moulding process and apparatus

An injection molding, super-large technology, which is applied in the field of super-large plastic injection molding technology and equipment, can solve the problems of lack of safety brake device, limitation of mold clamping capacity, poor safety, etc., and achieve improved clamping effect and strong clamping force function, effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

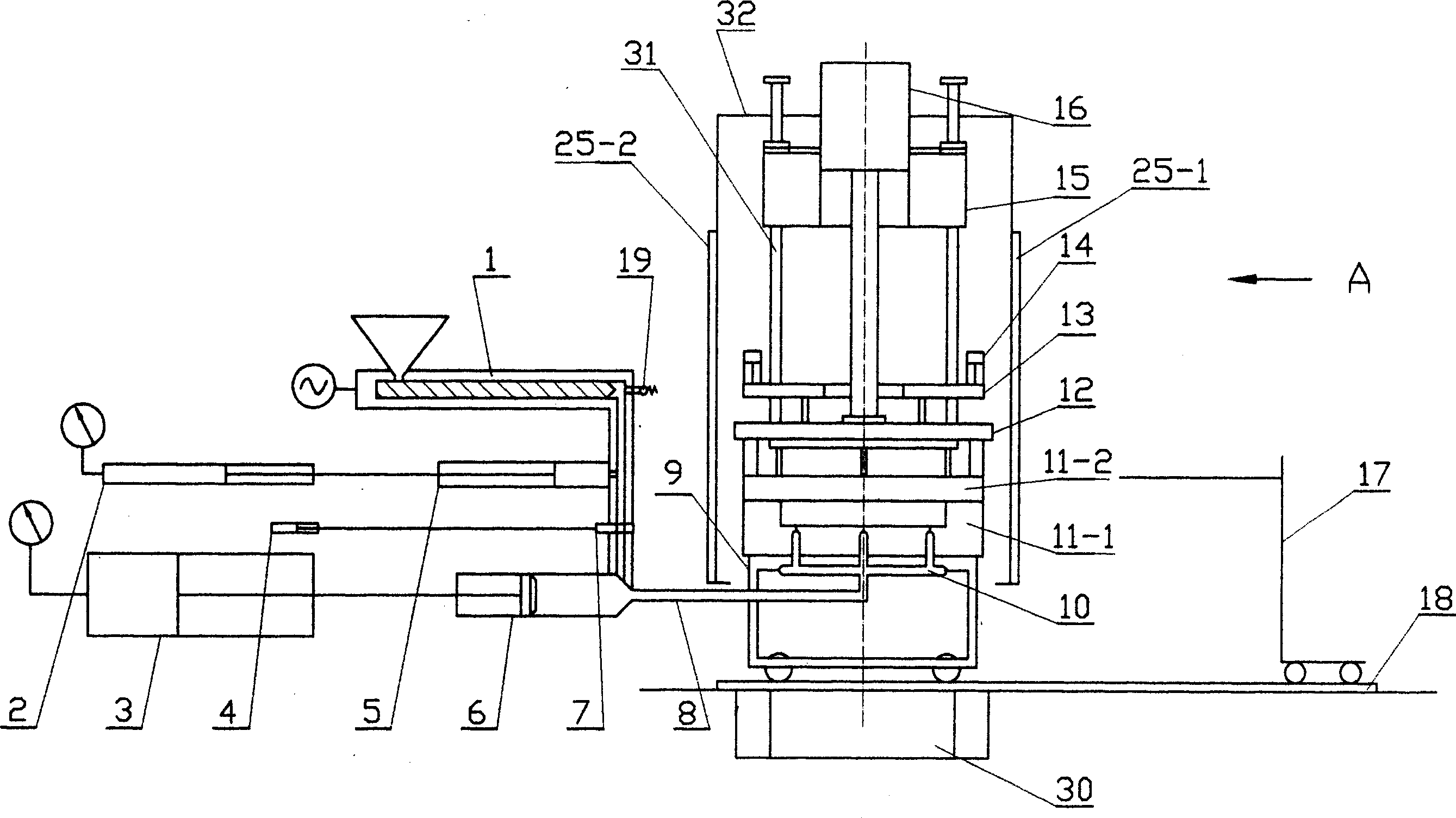

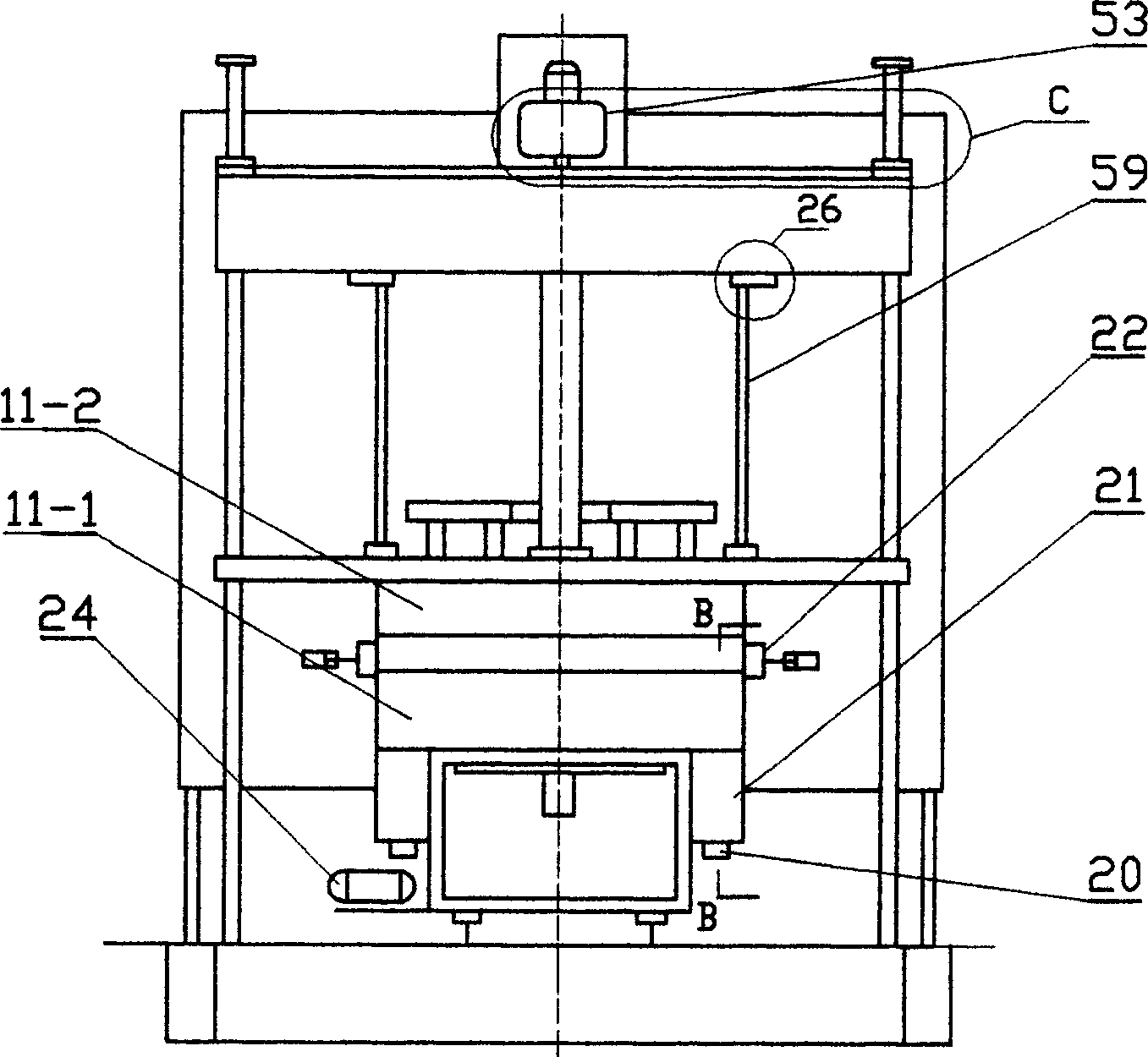

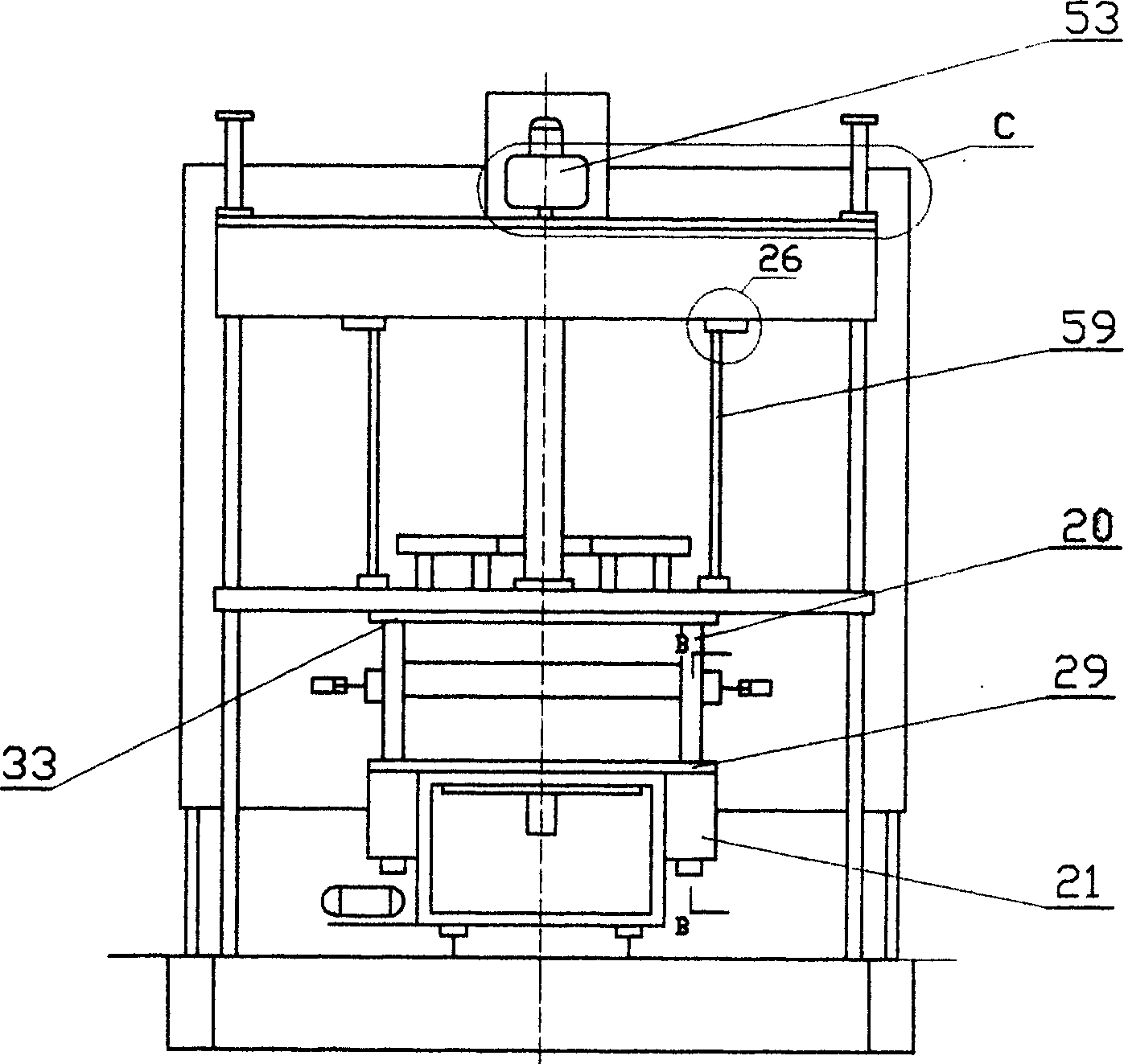

[0036] The invention provides a super-large plastic injection molding equipment, which mainly includes an injection molding and pre-molding mechanism; a mold clamping mechanism; a hydraulic system; and an electrical control system. There is a safety door; the mold clamp assembly 21 installed under the mold static mold 11-1 has a series oil cylinder and a multi-stage booster structure, and the junction of the mold guide column 20 and the symmetrical lock block 41 is a tooth-shaped groove; The mold thickness adjusting device assembly C that makes the upper machine base 15 drive the oil cylinder 16, the movable template 12, the push plate 13, and the ejection cylinder 14 to move up and down along the large guide pillar 31 is provided at the junction of the seat 15 and the large guide pillar 31; The brake safety device assembly 26 that makes the movable template 12 stop at any position is provided below the upper machine base 15 .

[0037] Described safety door comprises front saf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com