Method and apapratus for temperature circulation control

A temperature cycle and temperature control technology, applied in the direction of temperature control, non-electric variable control, control/regulation system, etc., can solve the problems of large loss of power, slow response, low efficiency, etc., to achieve energy saving, accurate and fast control, The effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

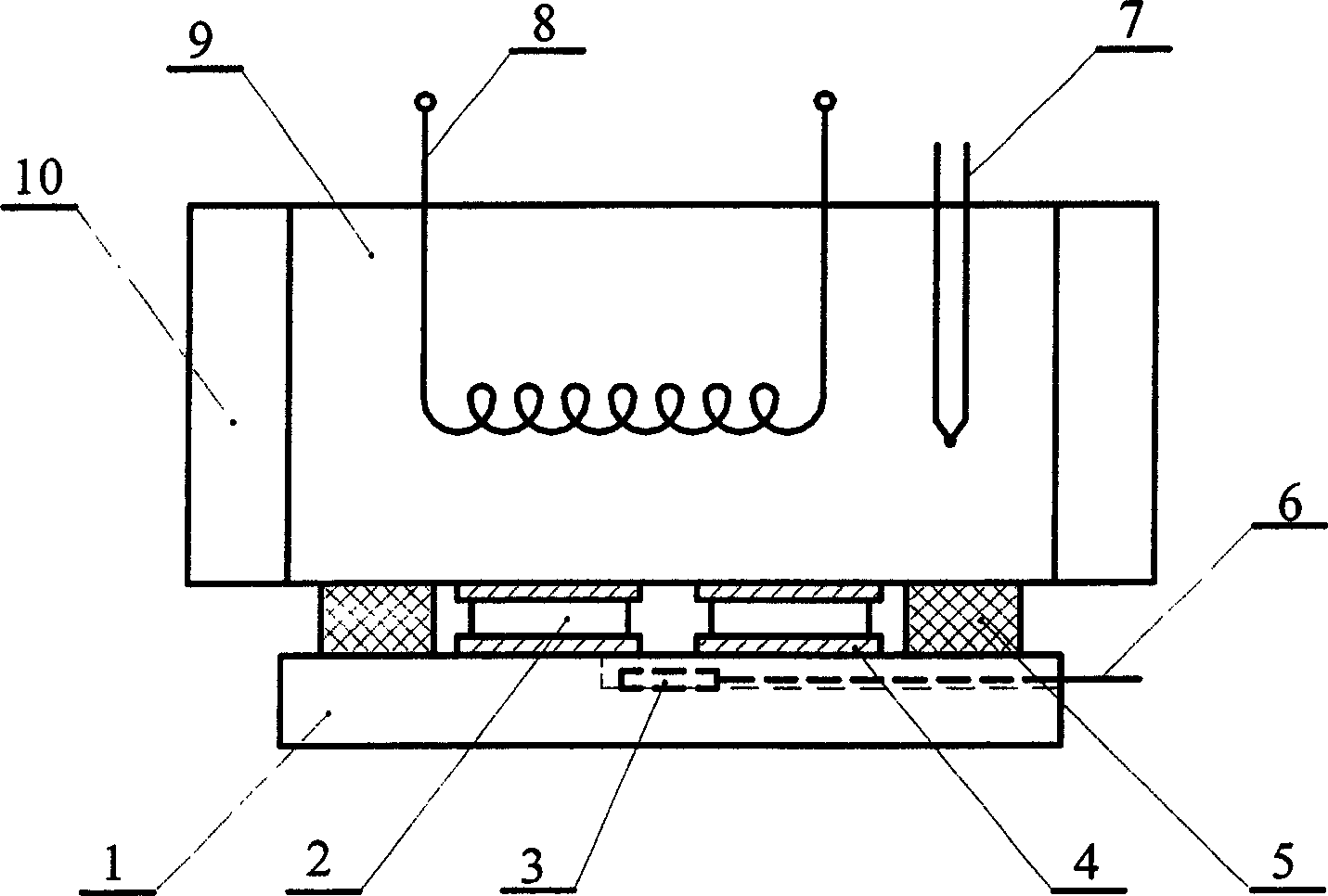

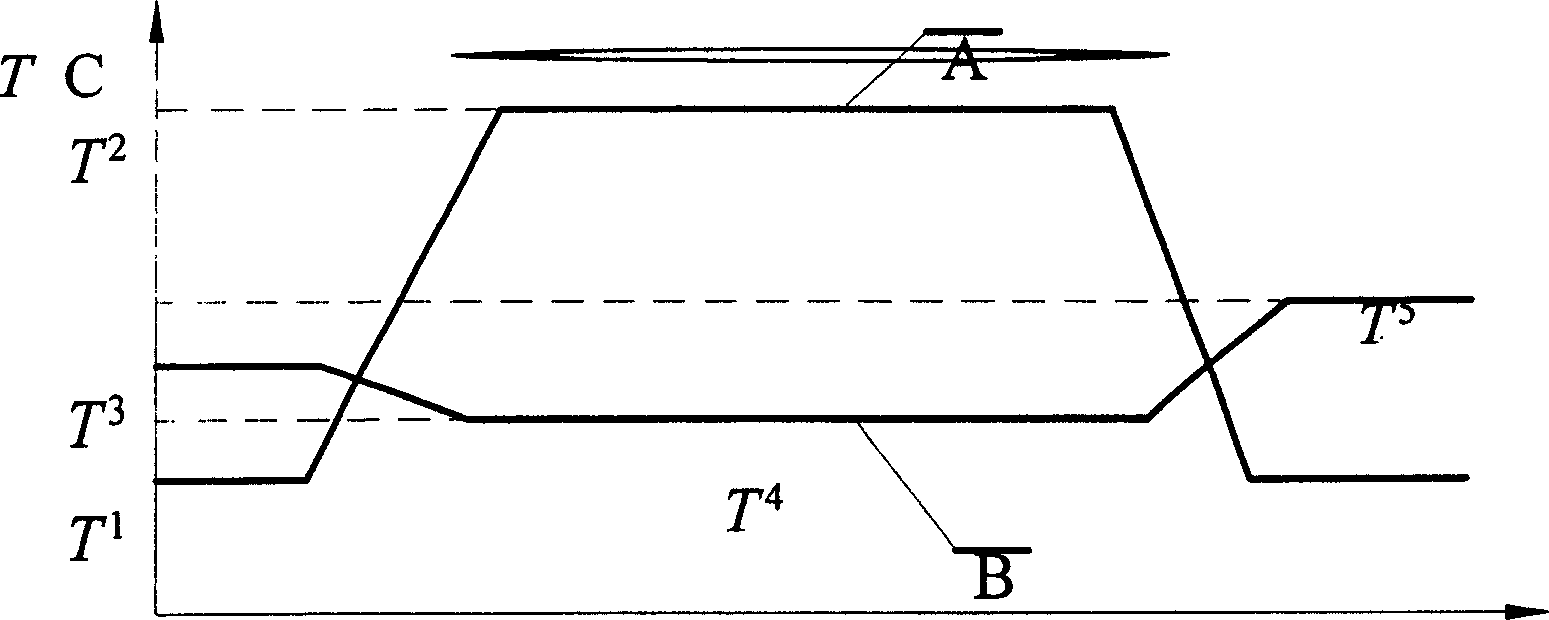

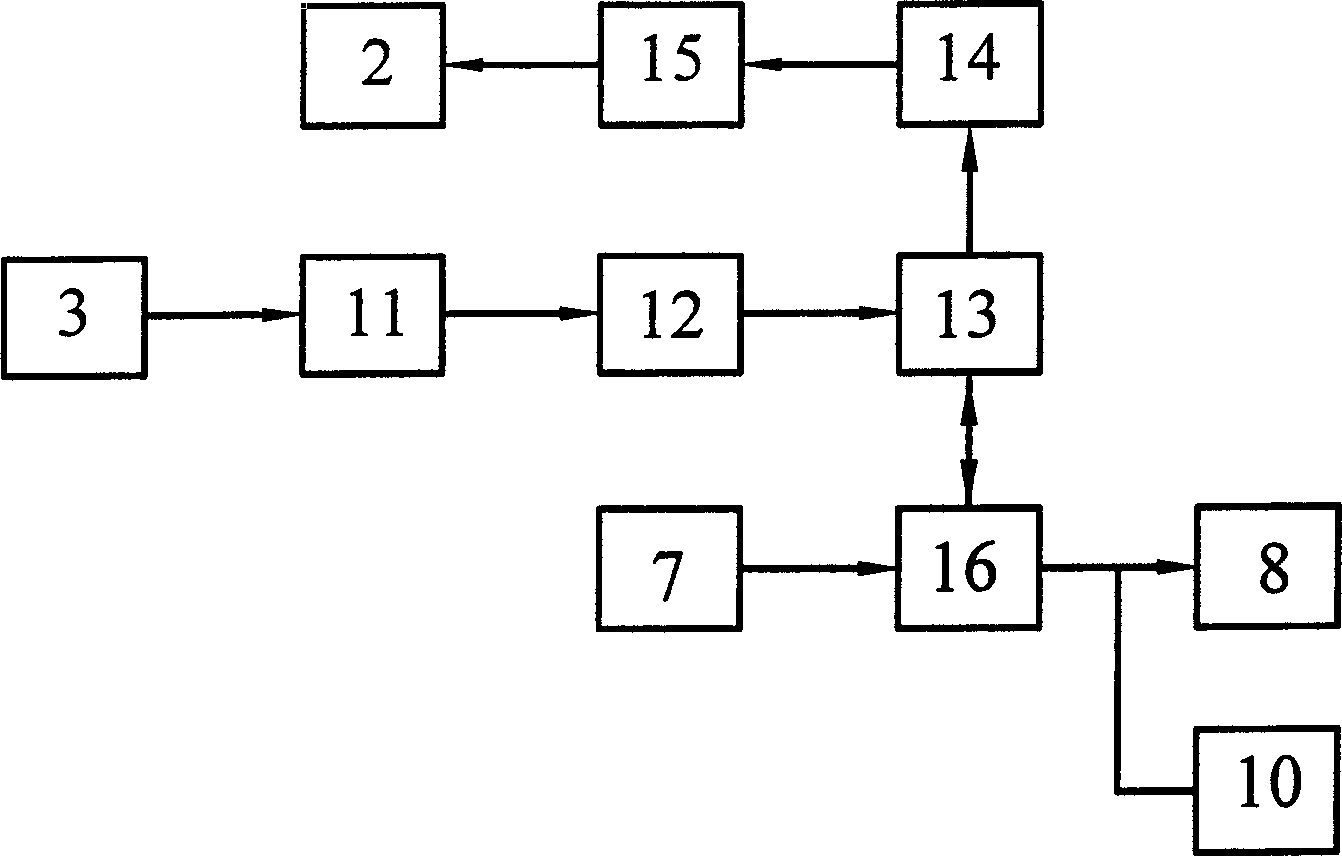

[0014] The specific implementation manner of an embodiment will be described in detail below in conjunction with the accompanying drawings.

[0015] The bonding process of a plastic microfluidic chip requires temperature control between 40°C and 105°C, and the temperature rise and fall rate is 30°C per minute. exist figure 1 In the installation diagram shown, the temperature control plate 1 that is in direct contact with the chip is a copper plate, and 4 semiconductor thermoelectric cooling devices 2 are selected, and the maximum cooling power of each piece is 80W. The regenerative oil tank made of heat-conducting material is an aluminum shell, filled with engine oil, and its heat capacity is about 10 times that of the temperature control board. Thermal conductive silicone rubber 4 is placed between the bottom of the oil tank and the semiconductor thermoelectric cooling device, and between the upper part of the temperature control plate and the semiconductor thermoelectric co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com