Time release calcium sulfate matrix for bone augmentation

A calcium sulfate, matrix technology, used in bone implants, aluminum/calcium/magnesium active ingredients, compression mold cups, etc., can solve the problem of exceeding the speed of new bone formation in patients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

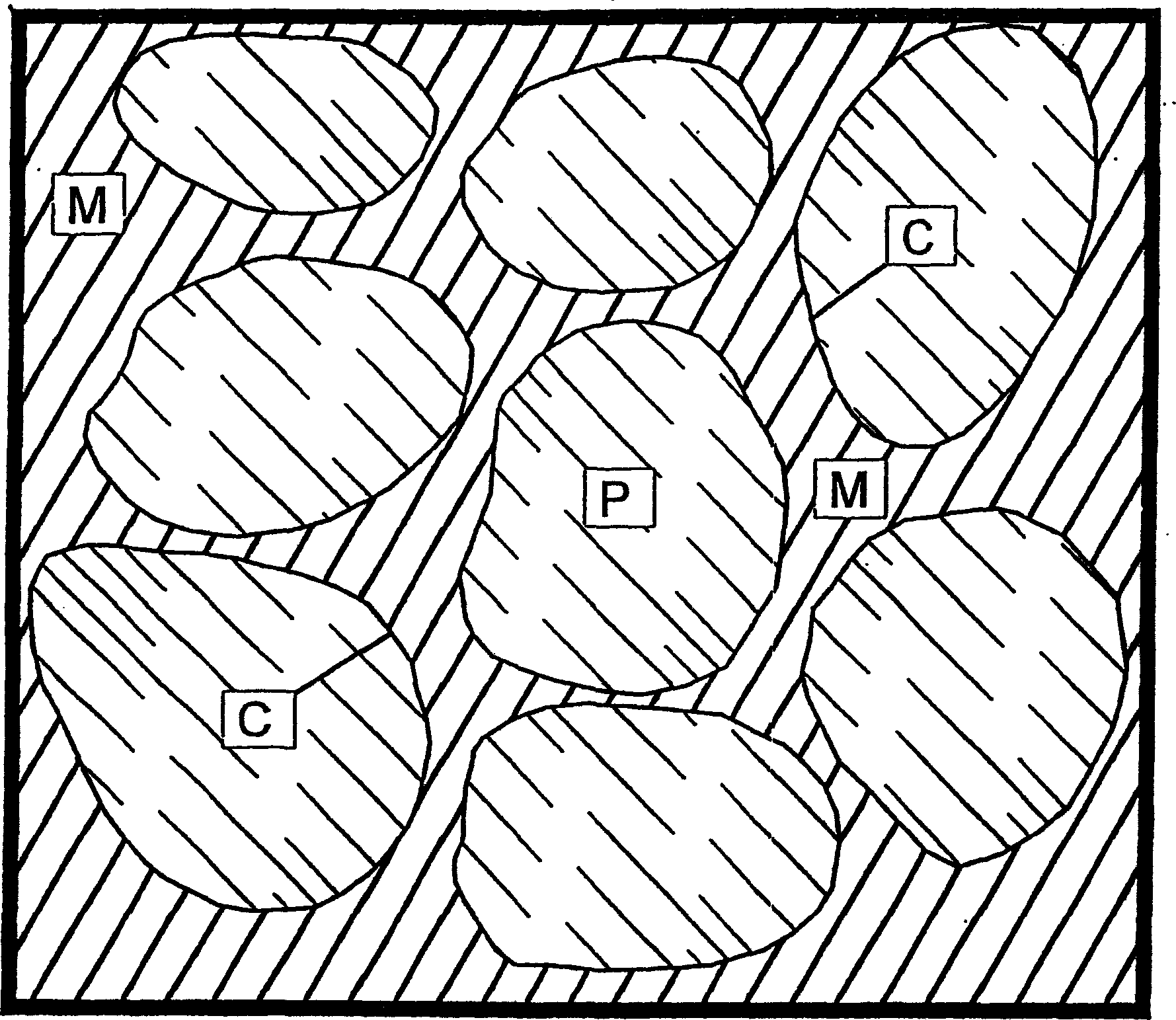

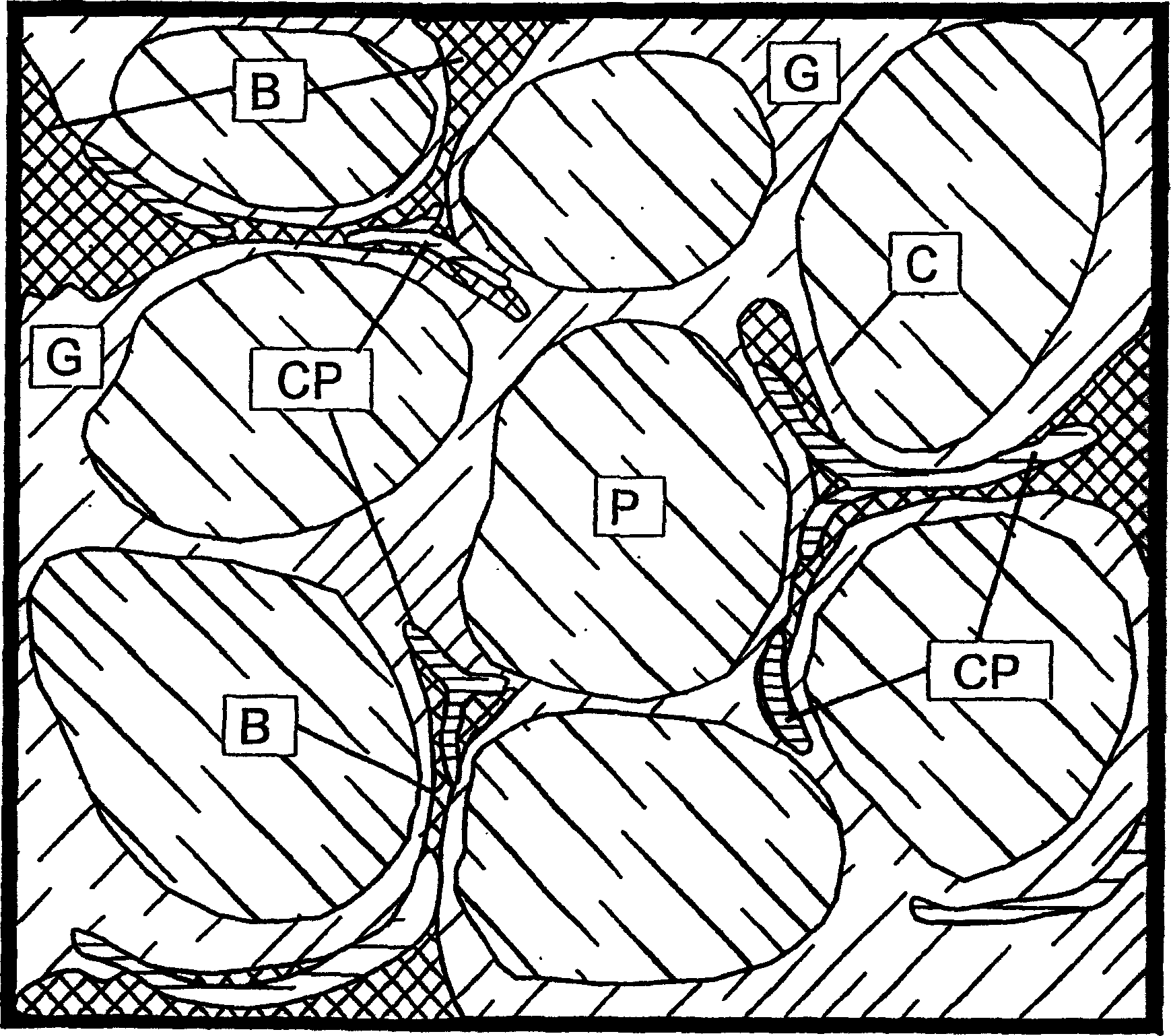

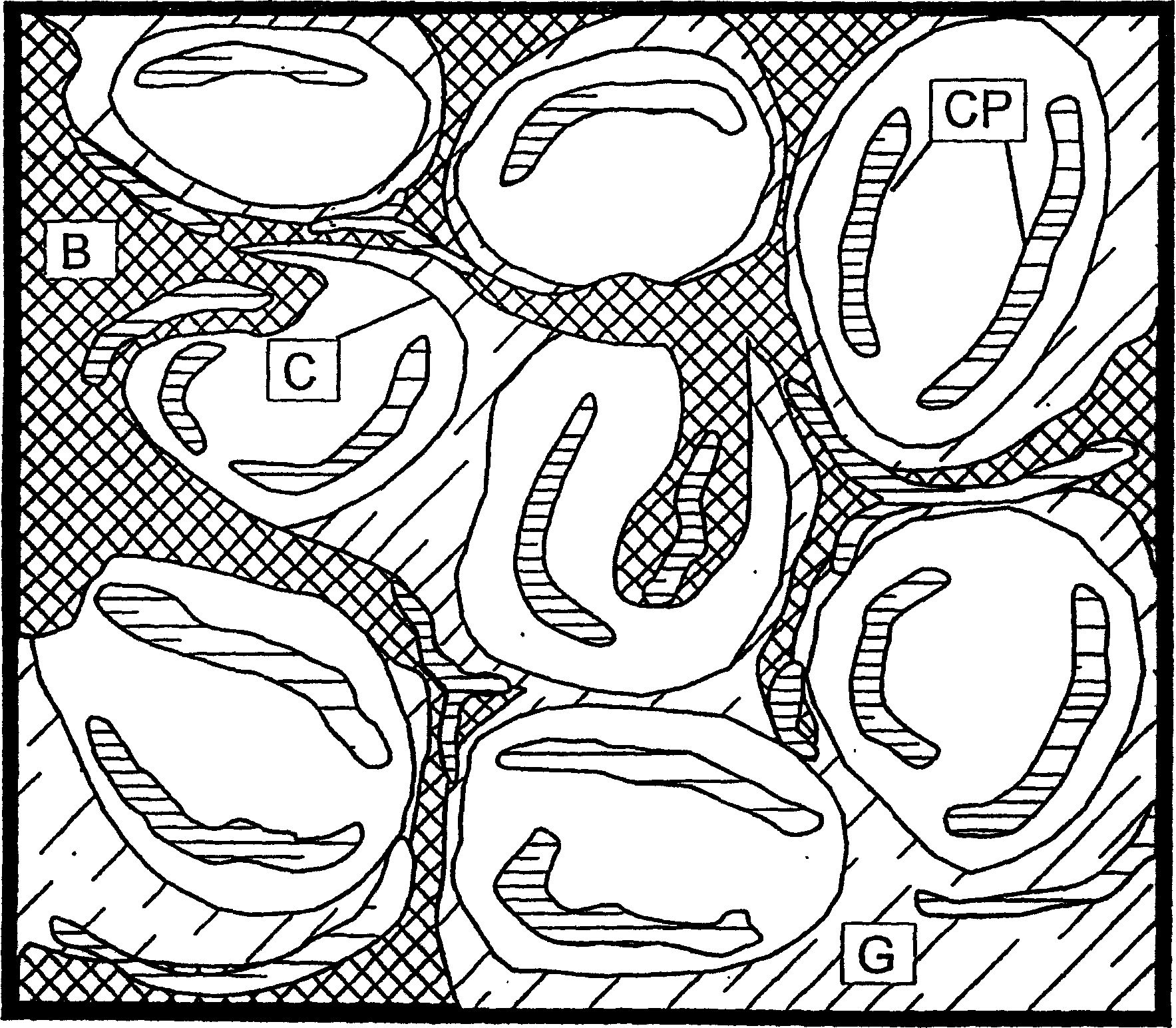

[0018] In one aspect, the present invention provides an implant composition having a controlled rate of resorption comprising a calcium sulfate compound, polymer-containing particles, and a curing agent for incorporating the calcium sulfate compound and the polymer-containing The particles of the substance solidify into a multiphase solid composition. Upon solidification, the calcium sulphate compound forms a matrix (M) in which the polymer-containing particles (P) are located. figure 1 Shown is a cross-sectional view of the heterogeneous solid implant composition before resorption occurs.

[0019] In another aspect, the present invention includes methods of using implant materials to prepare implant compositions of the present invention for bone augmentation and bone defect repair. The method comprises the steps of: (a) mixing calcium sulfate compound and polymer-containing particles with a curing agent into a mixture, (b) filling said mixture into an implant site, and (c) c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com