A communication method and common control bus interconnecting a controller and a precision measurement assembly

A precision measurement and controller technology, applied in the direction of measuring devices, general control systems, program control, etc., can solve problems such as inaccurate deformation, wire and cable traction, and limit servo characteristics, so as to improve measurement performance and reduce cable lines , The effect of reducing service costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

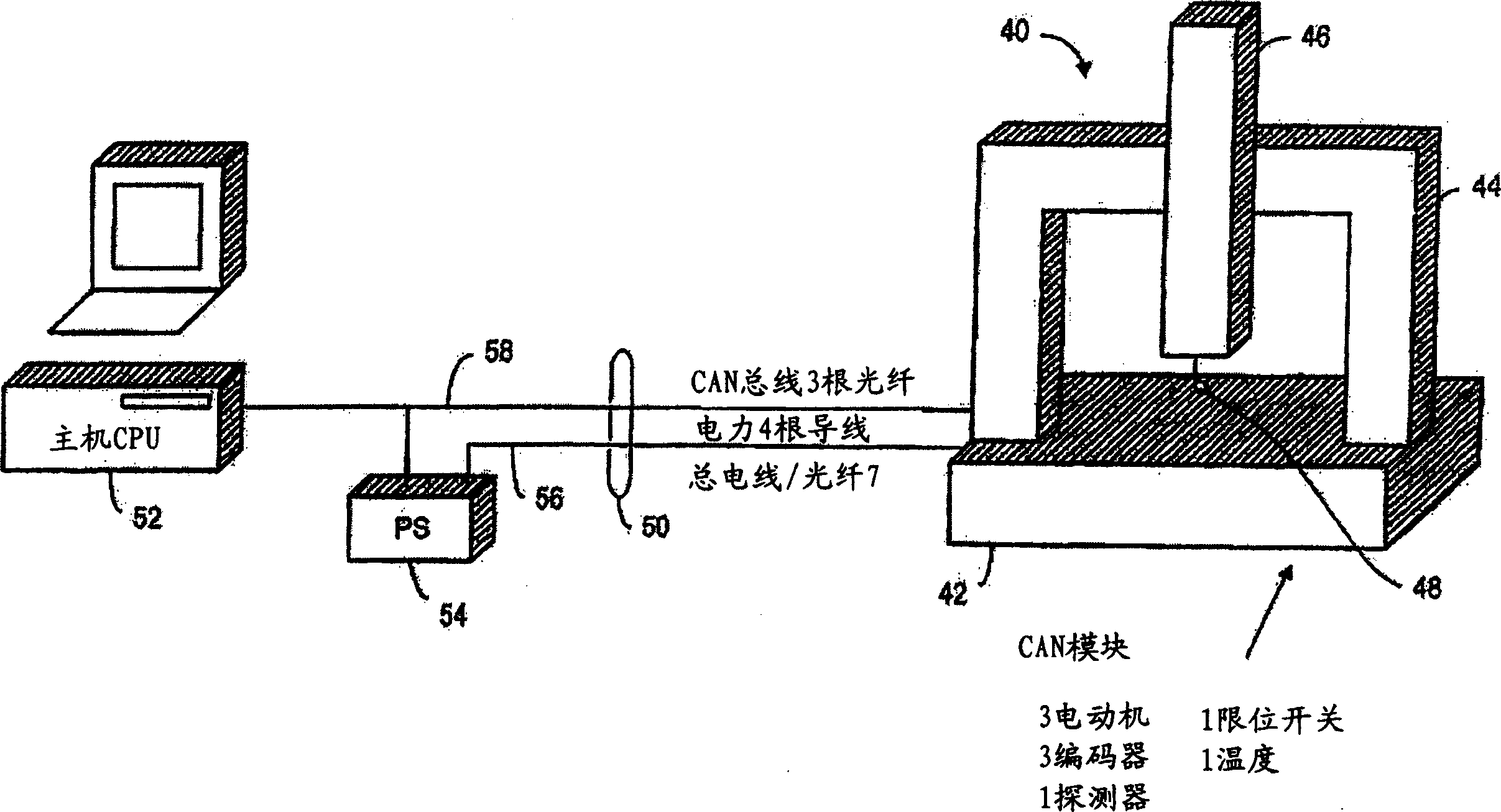

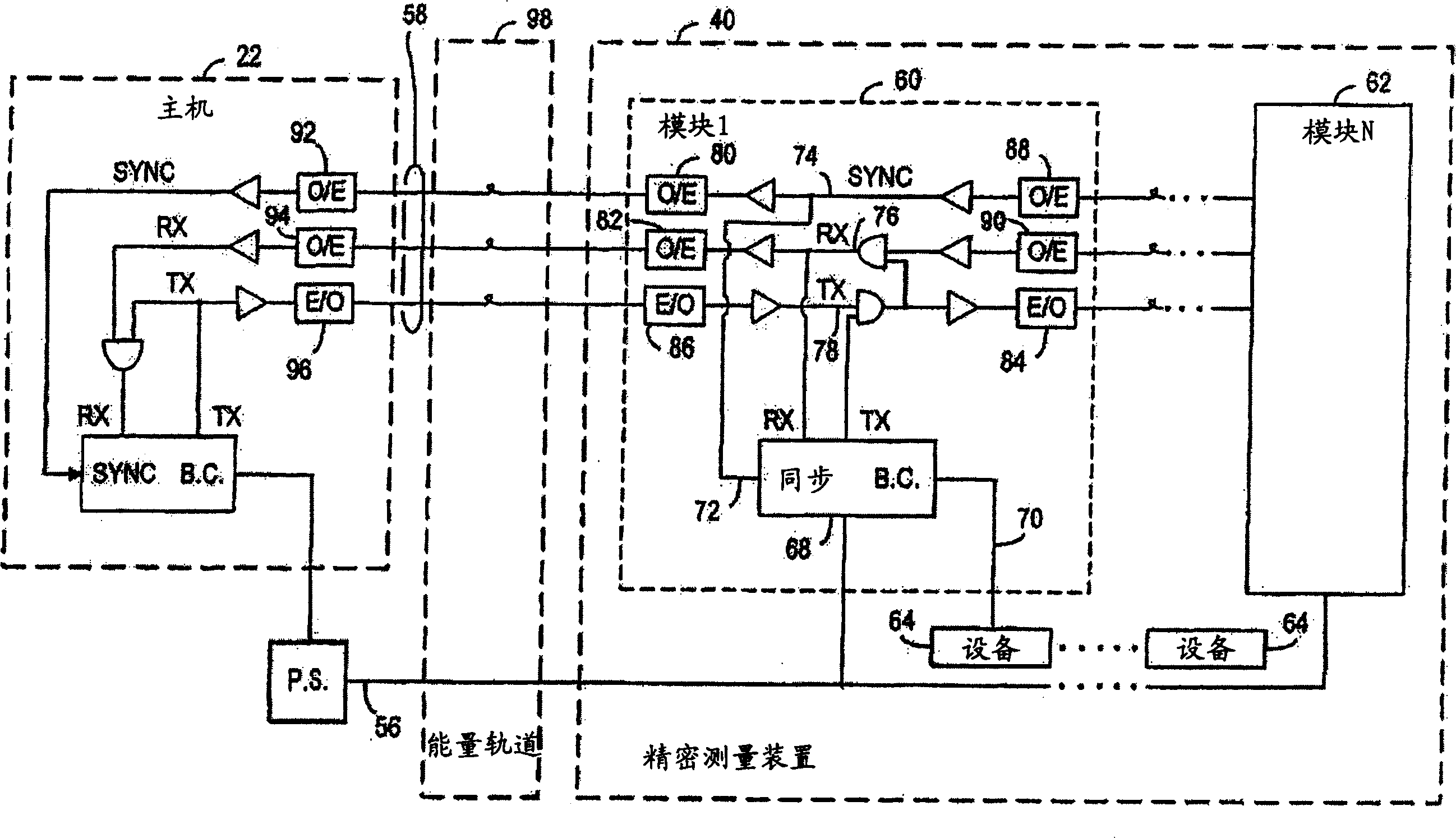

[0019] now refer to figure 2, shows a precision measurement device 40 having a platform 42 , a first movable part 44 (in this example a bridge 44 ), one or more supports 46 and a detector 48 . Various modules not shown but installed on or inside the precision measuring device 40, such as three motor modules for respectively connecting with one or more actuator motors, one or more motor modules for respectively connecting with one or more encoders Three encoder modules, a detection module for connecting with the detector 48, a limit switch module for connecting with one or more limit switches, and a temperature module for connecting with one or more temperature detectors. The modules may be interconnected as shown using a standard bus such as a known or customary serial network bus such as a CNN (Control Domain Network) bus or by a non-standard bus. CAN is a known serial bus system with multi-master capability according to ISO11898. Utilizing a shared or common bus allows for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com