Plant growing type porous concrete ball shape block

A technology of porous concrete and plant growth, applied in botany equipment and methods, container cultivation, gardening, etc., can solve problems such as unfavorable revetment or slope stability, affecting the growth of animals and plants, and destroying the ecological environment, so as to maintain a green natural landscape, Strong anti-corrosion ability, improve the effect of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

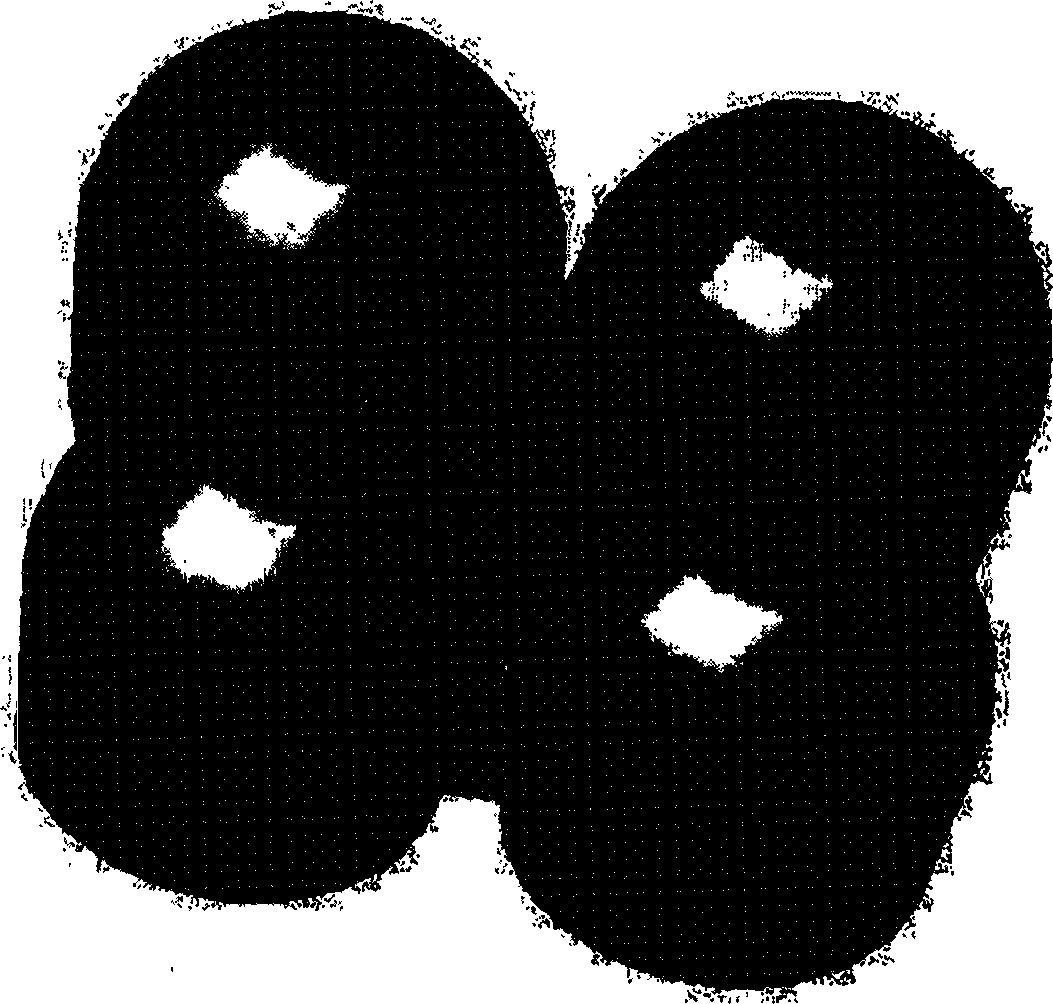

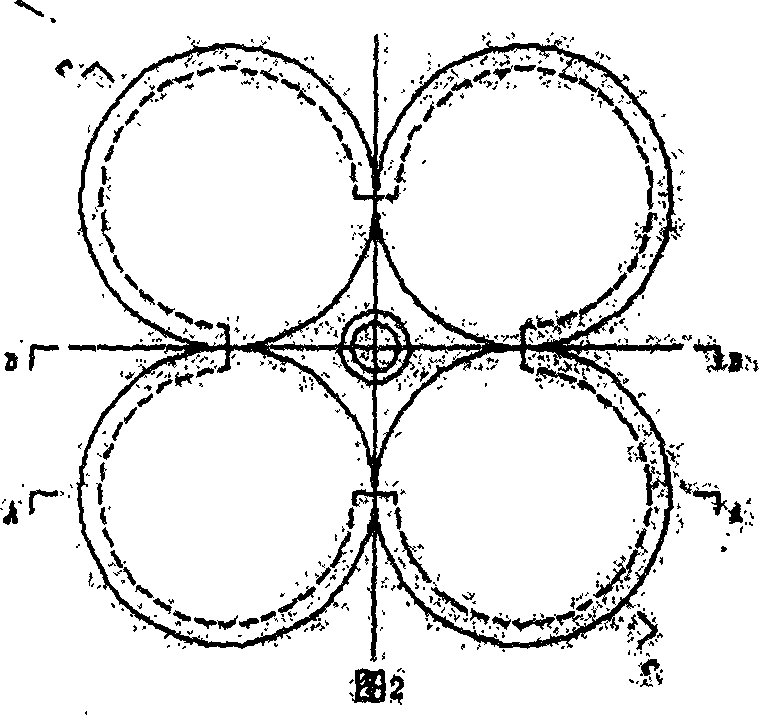

[0020] The block is composed of four parts with a spherical crown 1 at the top and a truncated cone 2 at the bottom, which are arranged symmetrically with the conical central hole 3 , and the parts between the four truncated cones 2 are solid cores 4 .

[0021] The present invention adopts 10-20mm single particle size crushing, and the dosage is 1400-1800kg / m 3 ; Portland cement of grade 42.5 and above, dosage 150-360kg / m 3 ; Mineral admixture (such as ground mineral powder, silicon powder, superfine fly ash), dosage 10 ~ 180kg / m 3 ; High-performance water reducing agent (water reducing rate above 20%), the dosage is 0.5-5.0% of the cementing material dosage. The compressive strength of the porous concrete prepared according to the above ratio is between 15-25MPa, and the porosity is between 20-30%. Use a mixer to stir, press or vibrate or tamp to shape.

[0022] Example: Variety and dosage of various raw materials: 42.5 grade Portland cement 280kg / m 3 ;Silicon powder 20kg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com