Giant magnet impedance effect composite wire with barrier layer and its preparing method

A technology of giant magneto-impedance and barrier layer, which is applied in the field of magneto-impedance effect composite wire and its preparation, can solve the problems of lower drive current frequency, affect the application of products, and poor performance repeatability, and achieve drive current frequency reduction and cost reduction. The effect of low and stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

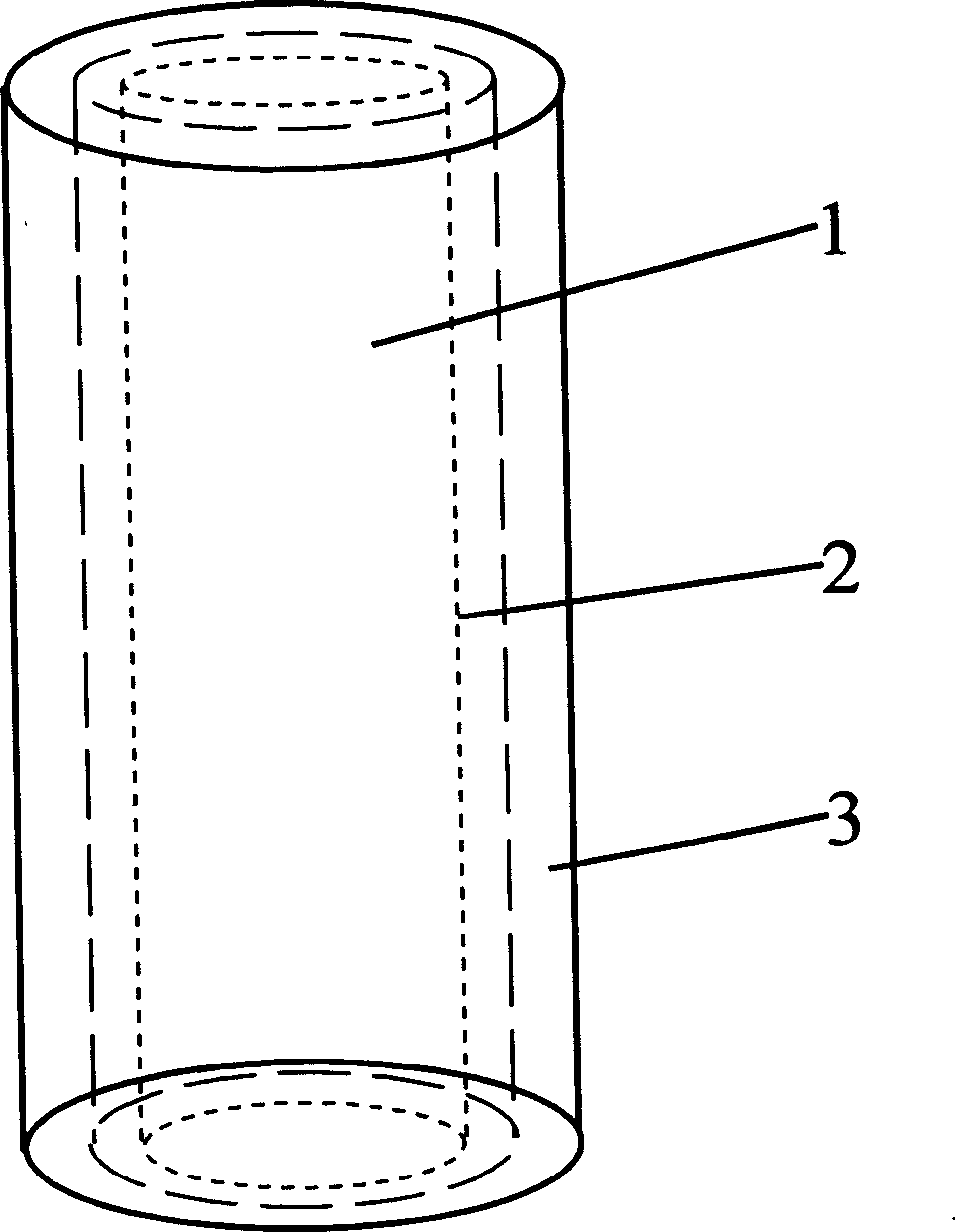

[0037] The first step The metal wire 1 is a copper wire with a diameter of 190 μm, and the barrier layer 2 is a polyester paint with a thickness of 2 μm.

[0038] The third step is electroless plating of the soft magnetic layer, that is, the soft magnetic layer 3 is NiFeB, FN=0.3, the plating time is 60 minutes, and the thickness of the coating is 9.0 μm.

[0039] The fourth step is annealing at 180°C for 30 minutes.

[0040] When the applied magnetic field is 0-60 Oersted and the driving current frequency is 1MHz, the amplitude of the impedance effect is 110%.

Embodiment 2

[0042] Step 1 Metal wire 1 is silver wire with a diameter of 100μm, barrier layer 2 is SiO 2 , with a thickness of 2 μm.

[0043] The third step is electroless plating of the soft magnetic layer, that is, the soft magnetic layer 3 is NiFeB, FN=0.3, the plating time is 45 minutes, and the thickness of the coating is 6.3 μm.

[0044] The fourth step is annealing at 220°C for 30 minutes.

[0045] When the applied magnetic field is 0-60 Oersted and the driving current frequency is 1MHz, the amplitude of the impedance effect is 152%.

Embodiment 3

[0047] The first step The metal wire 1 is a beryllium copper wire with a diameter of 100 μm, and the barrier layer 2 is a polyester paint with a thickness of 2 μm.

[0048] The third step is electroless plating of the soft magnetic layer, that is, the soft magnetic layer 3 is NiFeB, FN=0.3, the plating time is 30 minutes, and the coating thickness is 3.0 μm.

[0049] The fourth step is annealing at 200°C for 30 minutes.

[0050] When the applied magnetic field is 0-60 Oersted and the driving current frequency is 700KHz, the amplitude of the impedance effect is 212%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com