Heat sound refrigerator using noise as driving source

A technology of thermoacoustic refrigerator and driving source, which is applied in refrigerators, refrigeration and liquefaction, lighting and heating equipment, etc., and can solve problems such as consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

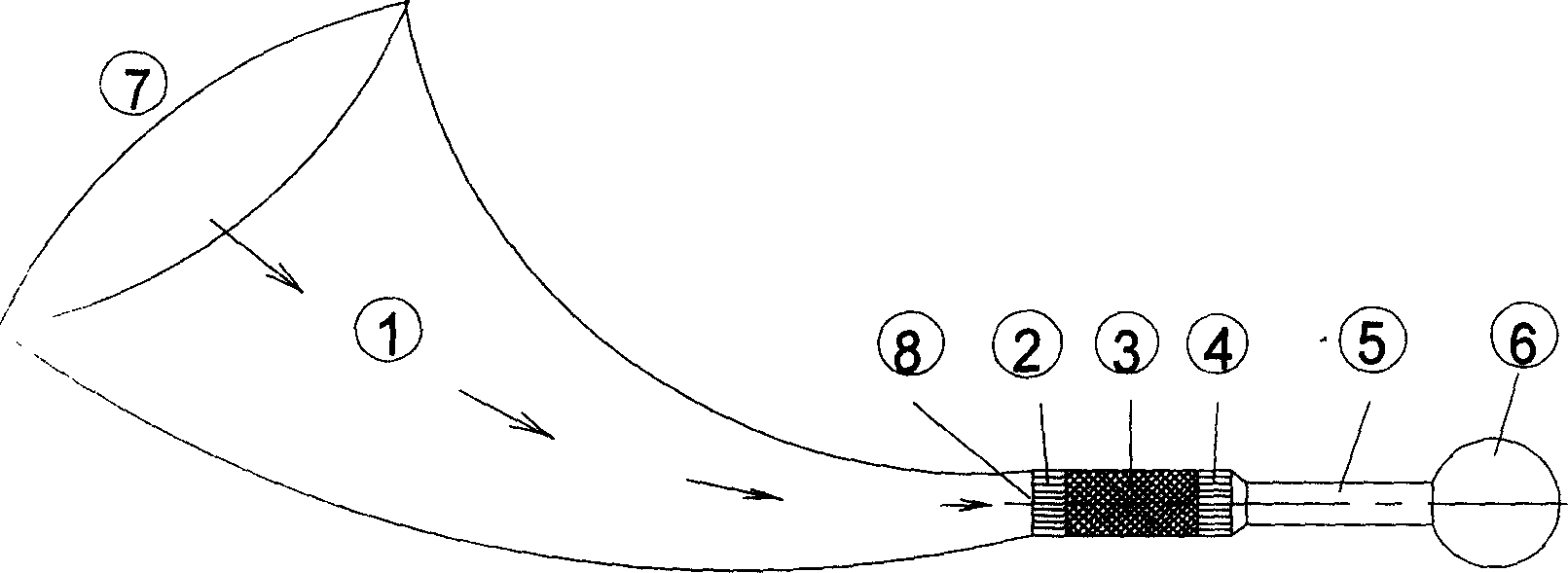

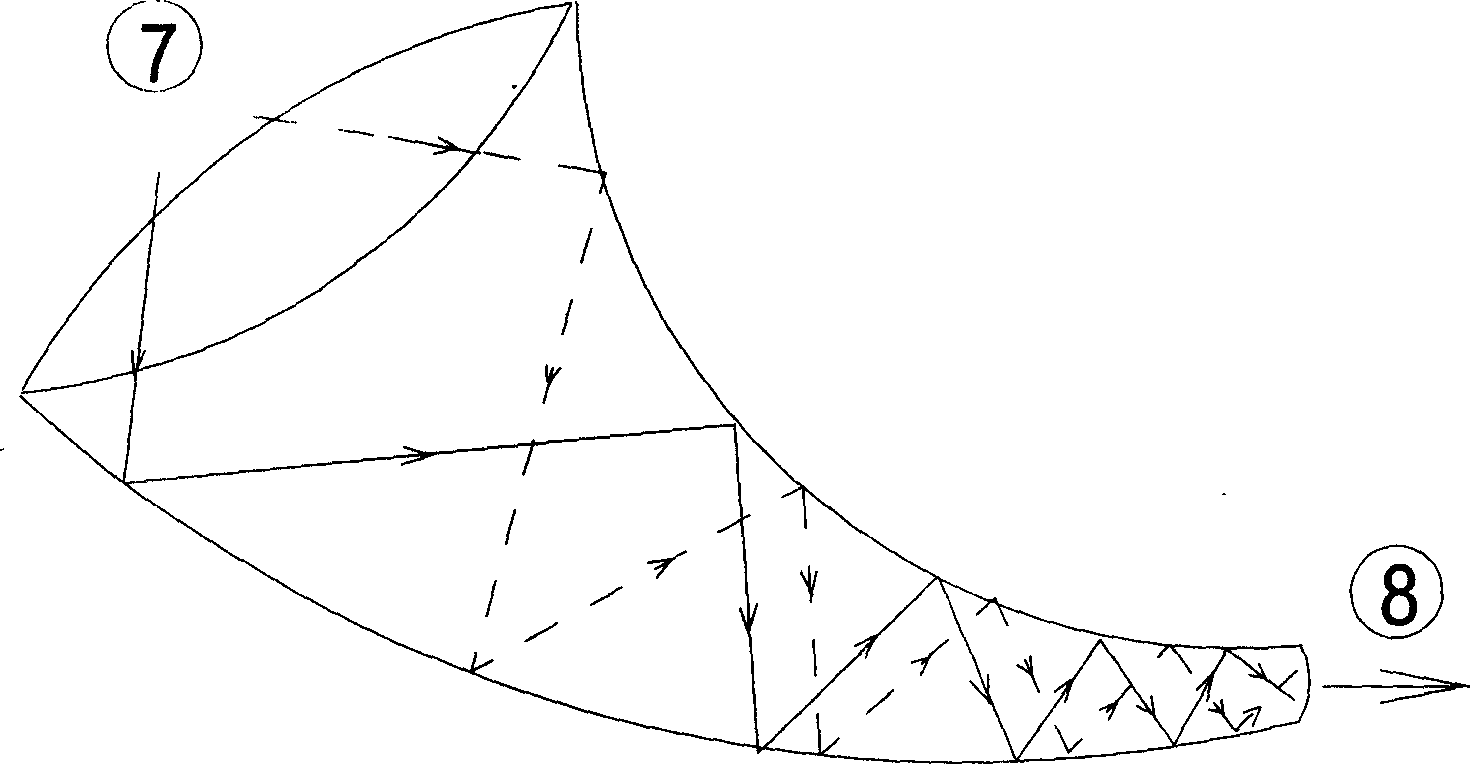

[0008] A thermoacoustic refrigerator with noise as the driving source is connected with a noise collector 1 , a hot-end heat exchanger 2 , a thermoacoustic plate stack 3 , a cold-end heat exchanger 4 , a resonant tube 5 and a resonant cavity 6 . The noise collector 1 is a "horn-shaped" sound channel, and is provided with a noise collector inlet port 7 and a noise collector outlet port 8 .

[0009] The noise collector is the driving source in the system. Although noise is ubiquitous in the environment, its sound pressure level is still too small to be directly exploited by the standards used to drive thermoacoustic refrigerators. In order to achieve the purpose of turning waste into treasure, the first consideration is to increase the sound pressure level. In view of the premise that we do not add new useful energy sources, it is necessary to use a mechanical method to concentrate the sound power of a relatively large area into a relatively small area, so that the sound flow d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com