Engine of mixing line wave thermal sound with bypass structure

A thermoacoustic engine and hybrid technology, applied in the direction of machines/engines, mechanical equipment, mechanisms that generate mechanical power, etc., can solve the problems of large loss of sound power and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

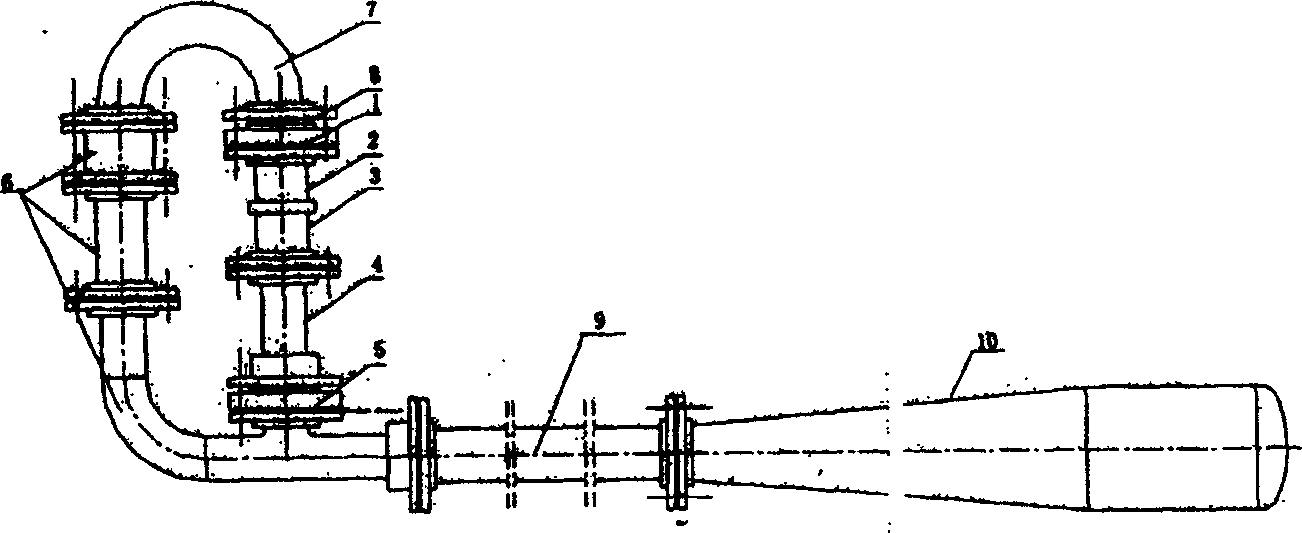

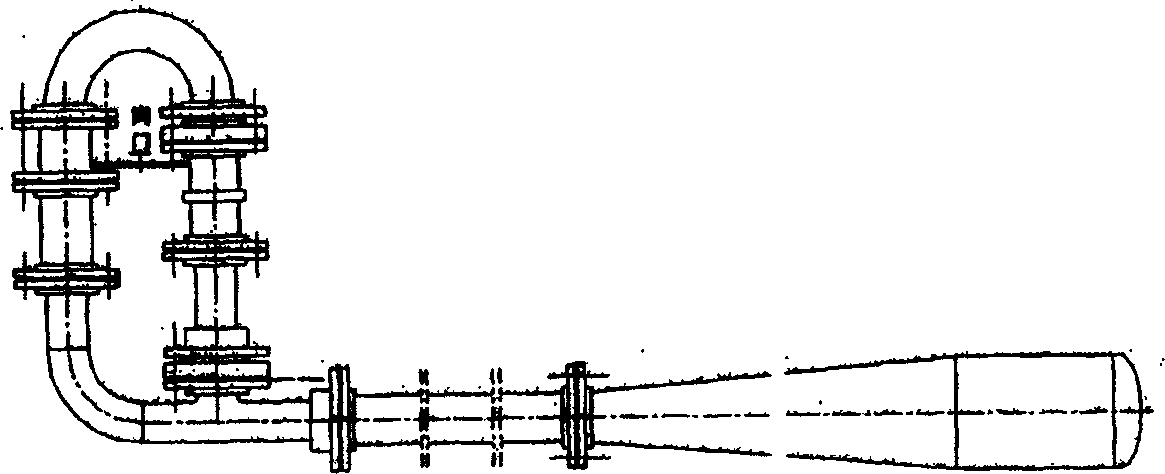

[0027] like figure 2 As shown, a hybrid traveling wave thermoacoustic engine with a bypass structure includes a feedback pipeline 6, a sound capacity pipeline 7, a jet pump 8, a main cooler 1, a thermoacoustic regenerator 2, and a heater 3. Thermal buffer pipe 4, sub-cooler 5, straight resonant path 9, muffler part 10, and a bypass structure is provided between the feedback pipeline 6 and the thermoacoustic regenerator 2. The bypass structure is a bypass pipe, and a valve for adjusting the flow rate of the sound work is arranged on the bypass pipe.

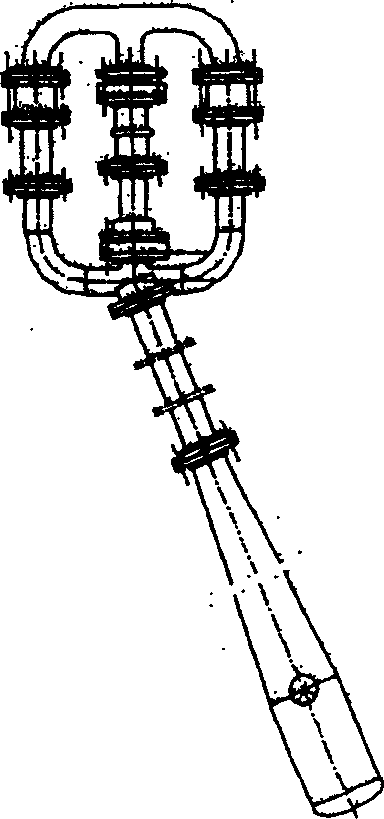

[0028] like image 3 As shown, another hybrid traveling wave thermoacoustic engine with a bypass structure includes a feedback pipeline 6, a sound volume pipeline 7, a jet pump 8, a main cooler 1, a thermoacoustic regenerator 2, a heating 3, heat buffer pipe 4, sub-cooler 5, straight resonant path 9, muffler part 10, and a second feedback line is connected to the entrance of the sound capacity pipeline 7 and the straight resona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com