Hyperpure, superfine silicon powder and preparation method

A technology of ultra-fine silicon powder and its production method, which is applied in the direction of silicon oxide, silicon dioxide, fibrous filler, etc., and can solve the problem of foreign exchange consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

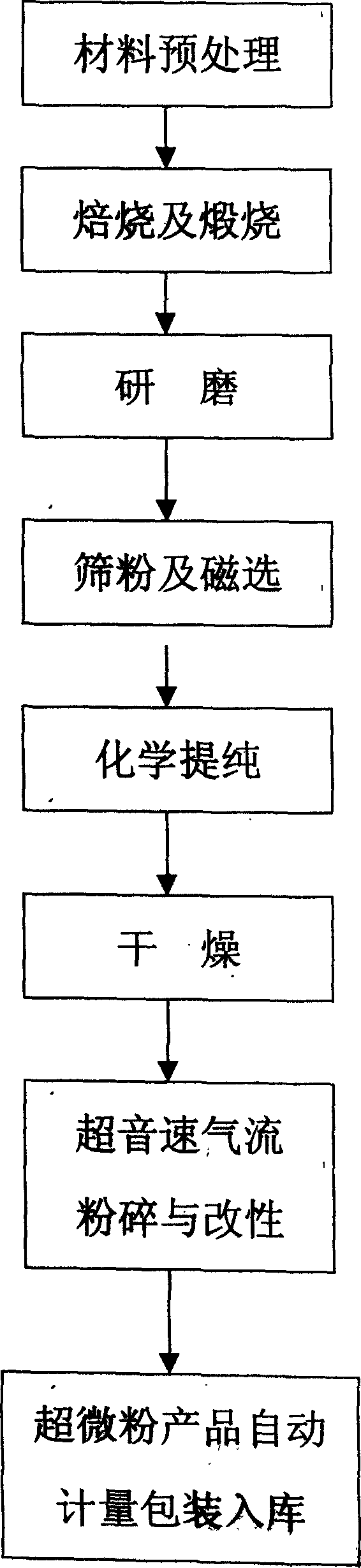

Method used

Image

Examples

Embodiment Construction

[0016] The main components of the silicon powder are: more than 99.96% of silicon dioxide, less than 0.003% of iron, the diameter of the silicon powder particles is less than 1 micron, and the outer surface of the silicon powder particles is coated with a silane coupling agent. The rest are some residual other metal elements, such as: silver, gold and so on.

[0017] 1. Material pretreatment:

[0018] First, beneficiation standard: SIO 2 ≥99.85% or more;

[0019] Second, appearance standard: A, white as jade; or B, crystalline and transparent; or C, black or reddish-yellow in the crystalline body;

[0020] Third, roughly crush the large raw ore block to 6-20 cm;

[0021] Fourth, wash the ore with clean water to remove impurities, then cool it in the sun, and manually select unqualified raw ore. Some lumps of ore are covered with a layer of impurities, which should be removed by grinding on a grinding wheel.

[0022] 2. Roasting and calcination:

[0023] The push plate typ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com