High temp, energy saving steel pipe type air preheater

An air preheater, steel tube technology, applied in lighting and heating equipment, combustion methods, indirect carbon dioxide emission reduction, etc., can solve problems such as difficult to solve thermal expansion, inability to meet new parameters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

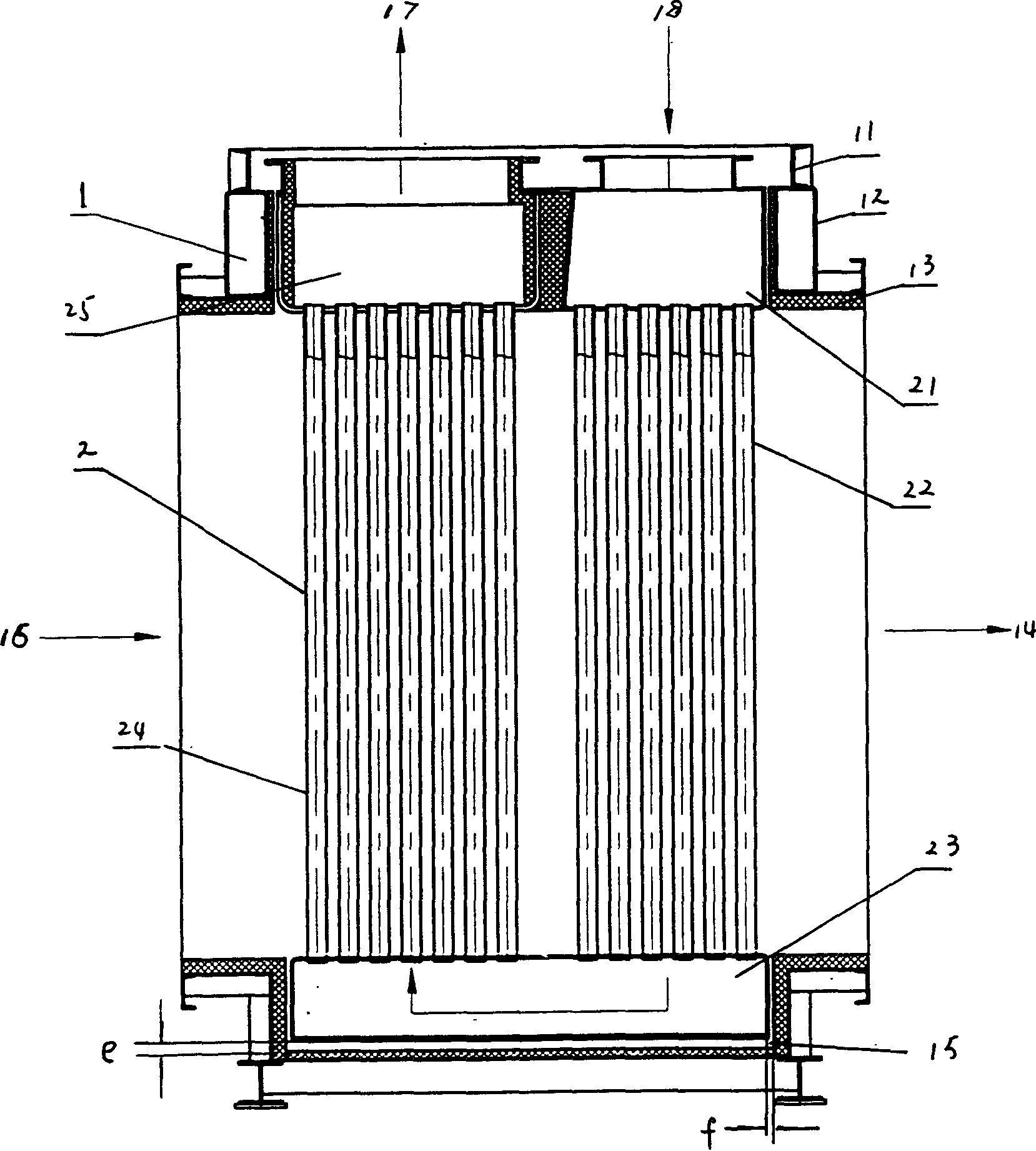

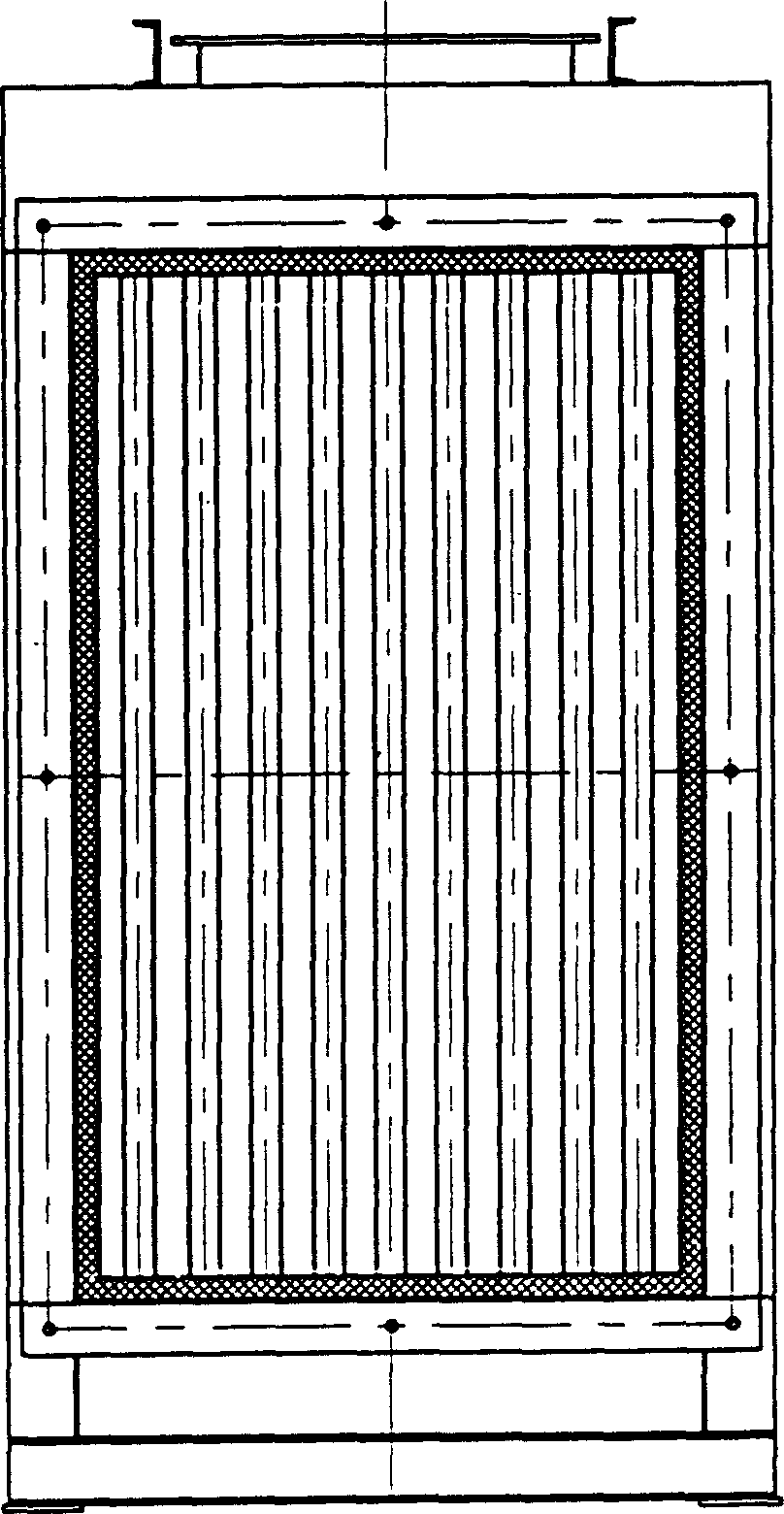

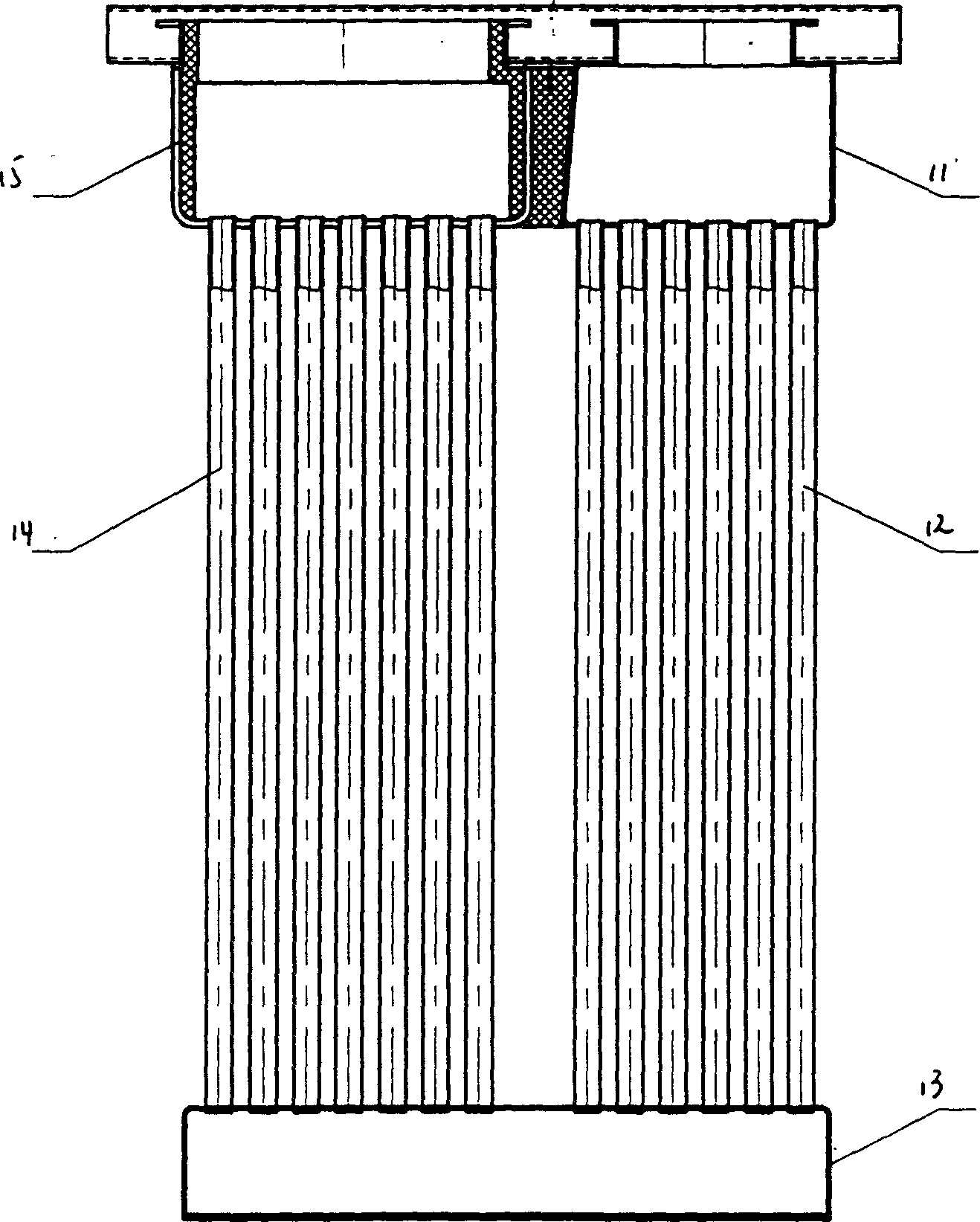

[0019] see Figure 1~2 , Figure 1~2 It is a cross-sectional view of the overall structure of the high-temperature energy-saving steel pipe-type air preheater with a single return tube bundle of the present invention. It mainly consists of a preheater shell 1 and a single return tube bundle 2 . The preheater shell 1 is composed of a steel frame 11 , a wall plate 12 and an inner lining 13 . A single return tube bundle 2 consists of a low-temperature header 21 with an inlet flange, a low-temperature tube bundle 22, an intermediate header 23, a high-temperature tube bundle 24, and a high-temperature header 25 with an inlet flange. The upper end of the tubes of the low-temperature tube bundle 22 is welded together with the bottom of the low-temperature header 21 according to the same tube spacing and row spacing; the tubes of the high-temperature tube bundle 24 are welded together with the bottom of the high-temperature header 25 according to the same tube spacing and row spacin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com