A kind of dewaxing method of ceramic shell

A ceramic type and dewaxing technology, which is applied in the direction of core, casting mold, casting mold composition, etc., can solve the problems of low crack rate, improve the pass rate and quality, ensure low crack rate, and delay the conduction of dewaxing heat Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

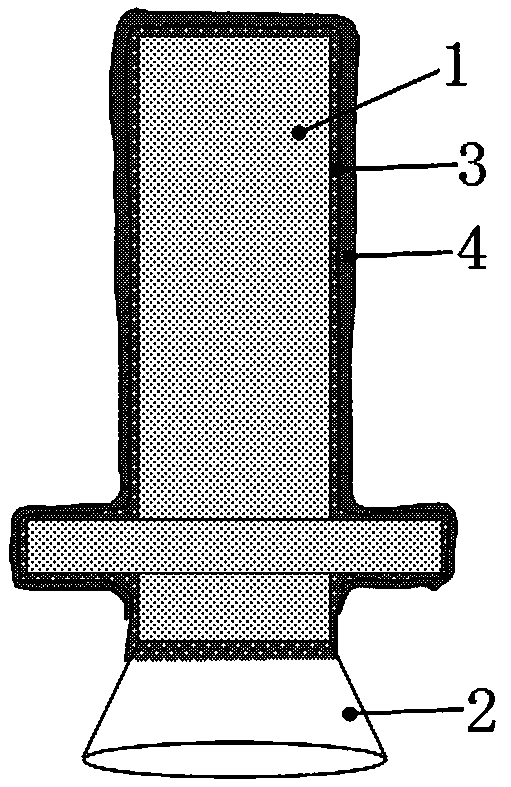

[0024] see figure 1 Shown, the present invention is the ceramic shell dewaxing method that gas turbine blade investment casting is used, and it comprises following process measure:

[0025] - making a ceramic shell 3 with a wax pattern 1 that meets the technical requirements of the dewaxing process, and there is no auxiliary dewaxing port structure design on the ceramic shell 3;

[0026] Before the ceramic shell 3 with the wax pattern 1 enters the dewaxing process, the sprue cup 2 on the ceramic shell 3 is used as the dewaxing port, and the dewaxing port (i.e. the sprue cup 2) is used on the outside of the ceramic shell 3 ) as the starting point to set a heat-resistant layer 4 with a thickness ranging from thin to thick. Specifically: starting from the outside of the dewaxing port of the ceramic shell 3, the melting point is lower than that of the wax mold 1 inside the ceramic shell 3. And after burning off, an amorphous meltable substance with minimal ash remaining outside t...

Embodiment 2

[0032] The present invention is the dewaxing method of the ceramic shell that gas turbine blade investment casting is used, and it comprises following process measure:

[0033] - Manufacture a ceramic shell with a wax pattern that meets the technical requirements of the dewaxing process, and there is no auxiliary dewaxing port structure design on the ceramic shell;

[0034]Before the ceramic shell with wax pattern enters the dewaxing process, the sprue cup on the ceramic shell is used as the dewaxing port, and the thickness is set at the outside of the ceramic shell starting from the dewaxing port (that is, the sprue cup) It is a differentiated heat resistance layer from thin to thick, specifically: starting from the external root at the dewaxing port of the ceramic shell, the melting point is lower than the wax pattern inside the ceramic shell, and after burning out, it is on the outside of the ceramic shell Amorphous meltable substance with minimal residual ash-preferably mi...

Embodiment 3

[0040] The present invention is a method for dewaxing ceramic mold shells for the investment casting of turbine blades of aero-engines, which comprises the following technological measures:

[0041] - Manufacture a ceramic shell with a wax pattern that meets the technical requirements of the dewaxing process, and there is no auxiliary dewaxing port structure design on the ceramic shell;

[0042] Before the ceramic shell with wax pattern enters the dewaxing process, the sprue cup on the ceramic shell is used as the dewaxing port, and the thickness is set at the outside of the ceramic shell starting from the dewaxing port (that is, the sprue cup) It is a differentiated heat-resistant layer from thin to thick, specifically: starting from the outside of the ceramic shell dewaxing port, the melting point is lower than the wax pattern inside the ceramic shell, and it remains outside the ceramic shell after burning out Amorphous meltable substance with minimal ash content-preferably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com