Silicon rubber composition and its preparation process and use

A technology of silicone rubber composition and silicone raw rubber, which is applied in the field of silicone rubber composition and its preparation, can solve problems such as resistance to hydrolysis and unsatisfactory bonding, and achieve the effect of improving bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Prepare silicone rubber according to the following ratio:

[0020] 107 raw silicon rubber (Beijing Chemical Plant) 100 parts by weight

[0021] Ethyl Tetrasilicate (Beijing Xinzhong Chemical Factory) 3 parts by weight

[0022] Dibutyltin dilaurate (Beijing Chemical Plant) 0.4 parts by weight

[0023] No. 2 white carbon black (Shenyang Chemical Plant) 10 parts by weight

[0024] Titanium dioxide (Beijing Chemical Plant) 40 parts by weight

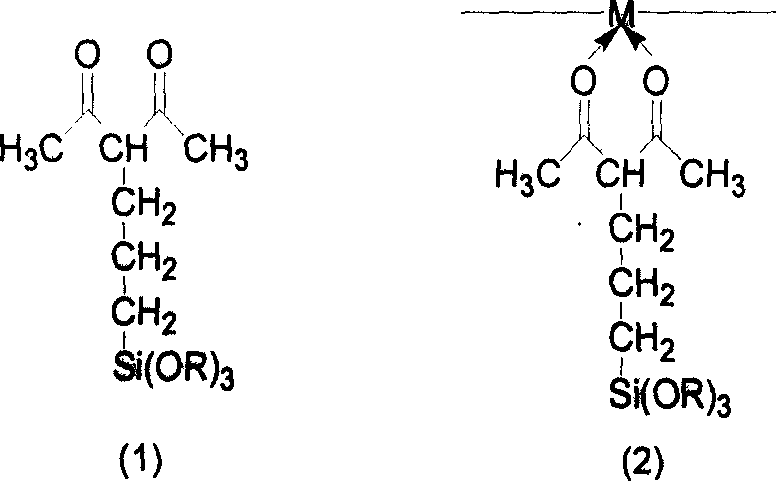

[0025] γ-(3-Acetylacetonyl)propyltrimethoxysilane (self-made) 1 part by weight

[0026] 1% gamma-(3-acetylacetonate) propyltrimethoxysilane ethanol solution was applied on the surface of 304# stainless steel and dried. After standing at room temperature for 24 hours, the stainless steel test piece was bonded with the above-mentioned silicone rubber. Place it at room temperature for 7 days to fully cure the silicone rubber. The shear strength test results are as follows:

[0027] Shear Strength Failure Mode

[0028] 2.95MPa coh...

Embodiment 2

[0041] Prepare silicone rubber according to the following formula:

[0042] 107 raw silicon rubber (Beijing Chemical Plant) 100 parts by weight

[0043] Ethyl Tetrasilicate (Beijing Xinzhong Chemical Factory) 3 parts by weight

[0044] Dibutyltin dilaurate (Beijing Chemical Plant) 0.4 parts by weight

[0045] No. 2 white carbon black (Shenyang Chemical Plant) 10 parts by weight

[0046] Titanium dioxide (Beijing Chemical Plant) 40 parts by weight

[0047] γ-(3-Acetylacetonyl)propyltrimethoxysilane (self-made) 1-5 parts by weight

[0048] The brass test piece was bonded with the above-mentioned silicone rubber. Place at room temperature for 24h, and treat at 100°C for 6h. The shear strength test results are as follows:

[0049] γ-(3-Acetylacetonyl)propyltri

[0050] 0 1 3 5

[0051] Methoxysilane content (weight points)

[0052] Shear strength (MPa) <0.5 2.46 2.79 2.83

[0053] Failure mode Adhesive failure Cohesive failure Cohesive failu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com