Safety valve assembly

A technology of safety valve and valve group, which is applied in the field of composite valves, can solve problems such as being easily affected by external forces, unreasonable structure, and insufficient sealing performance, and achieve the effects of flexible rotation, compact structure, and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

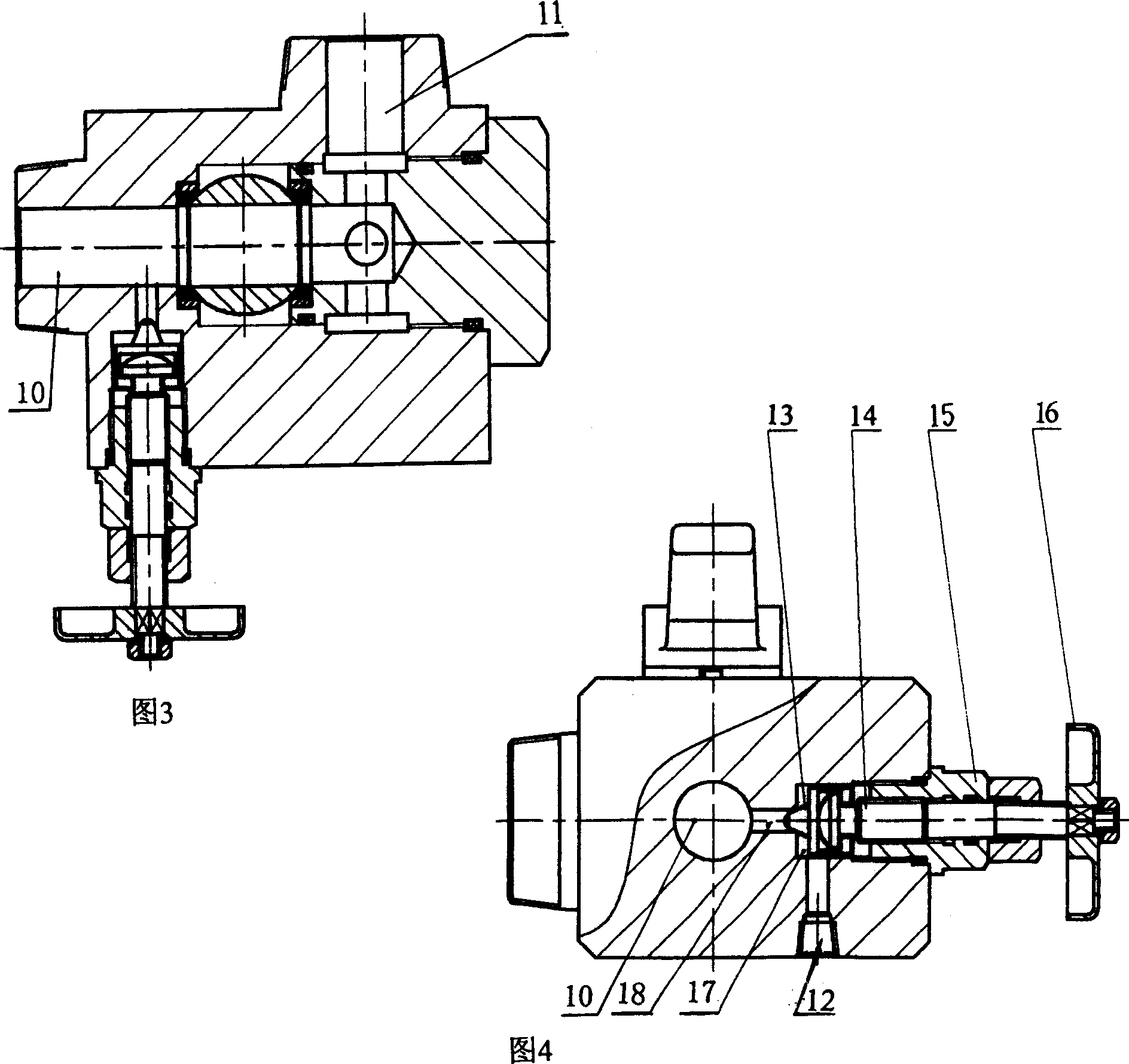

[0014] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

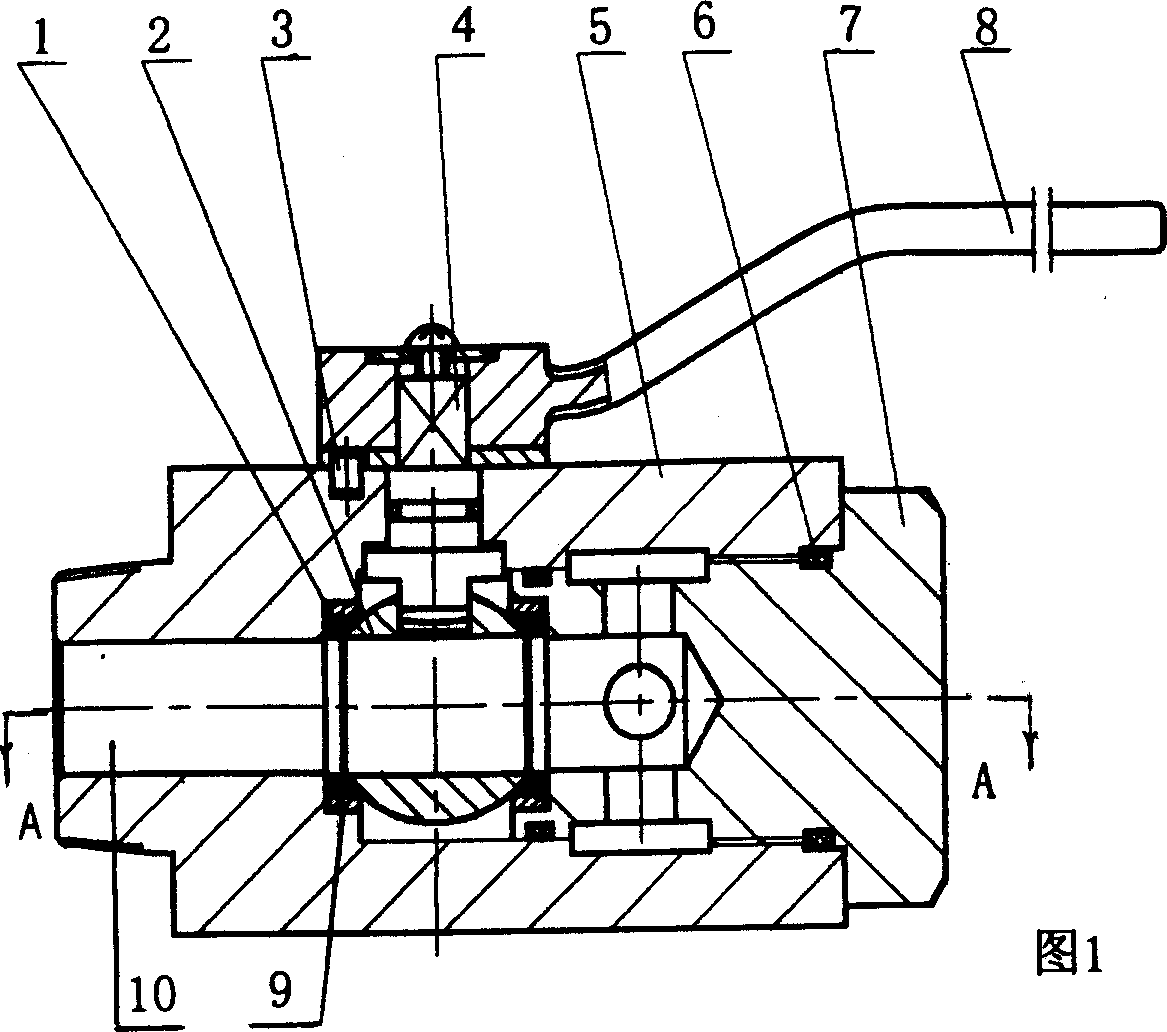

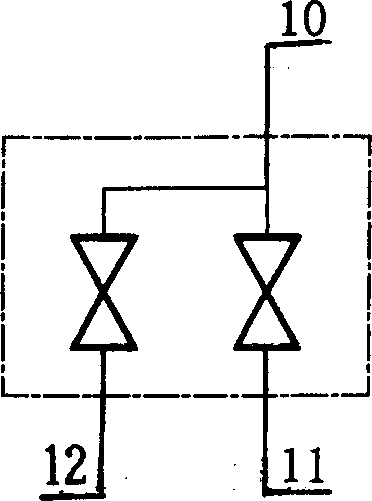

[0015] The valve body 5 is a cuboid, and there are bosses with conical external threads on the two surfaces perpendicular to each other. In the middle of the bosses, there are oil ports 10 connected to the accumulator, oil ports 11 connected to the system oil source, two oil ports 10, 11 The centerline of the centerline is in the plane of Gang 1, and the lower surface has the oil port 12 connected to the oil tank, and the other surface opposite to the oil port 10 is an opening with internal thread, and the other surface opposite to the oil port 11 has a communication channel with the oil port 10. Holes, seat holes 17, unloading runners 18, and the oil port 10 in the middle of the valve body and the opening are stepped holes that communicate with each other, and the upper surface has a through hole that communicates with the middle stepped hole.

[0016] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com