Preparation method of white organic electroluminescent device

An electroluminescence and electromechanical technology, applied in the field of preparation of white organic electroluminescence devices, can solve the problems of lack of spectral stability and poor spectral stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Doping DCJTB into NPB as a light-emitting layer to prepare a structure of ITO / NPB / DCJTB: NPB / NPB / BCP / Alq 3 / LiF / Al electroluminescent device, in a vacuum of 10 -4 Evaporate the organic and metal electrode layers under the pressure of Pa, the evaporation rate of the organic layer is controlled at 2 Å / s, the evaporation rate of LiF is controlled at 0.5 Å / s, the evaporation rate of the metal is controlled at 5 Å / s, and the doping concentration Controlled at 1%, among them, NPB layer thickness is 30~35nm, DCJTB: NPB layer is 3~5nm, NPB layer is 8~10nm, BCP layer is 9~10nm, Alq 3 The thickness of the LiF layer is 25-30nm, the thickness of the LiF layer is 0.8-1.5nm, and the thickness of the Al layer is 80-100nm. The obtained device is driven by DC voltage, and white light can be obtained. The maximum current efficiency is 3.15cd / A, and the maximum brightness is 3669cd / m 2 .

Embodiment 2

[0045] Doping DCJTB and TPB into NPB as the light-emitting layer is prepared into a structure of ITO / NPB / DCJTB: NPB / TPB: NPB / BCP / Alq 3 / LiF / Al electroluminescent device, in a vacuum of 10 -4 The organic and metal electrode layers were evaporated under the pressure of Pa, the evaporation rate of the organic layer was controlled at 2 Å / s, the evaporation rate of LiF was controlled at 0.5 Å / s, and the evaporation rate of metal was controlled at 5 Å / s. The concentration is controlled at 1%, among which, the thickness of NPB layer is 25-30nm, DCJTB: NPB layer is 8-10nm, TPB: NPB layer is 9-10nm, BCP layer is 8-10nm, Alq 3 The thickness of the LiF layer is 25-30nm, the thickness of the LiF layer is 0.8-1.5nm, and the thickness of the Al layer is 80-100nm. The obtained device is driven by DC voltage, and white light can be obtained. The maximum current efficiency is 4.33cd / A, and the maximum brightness is 6183cd / m 2 .

Embodiment 3

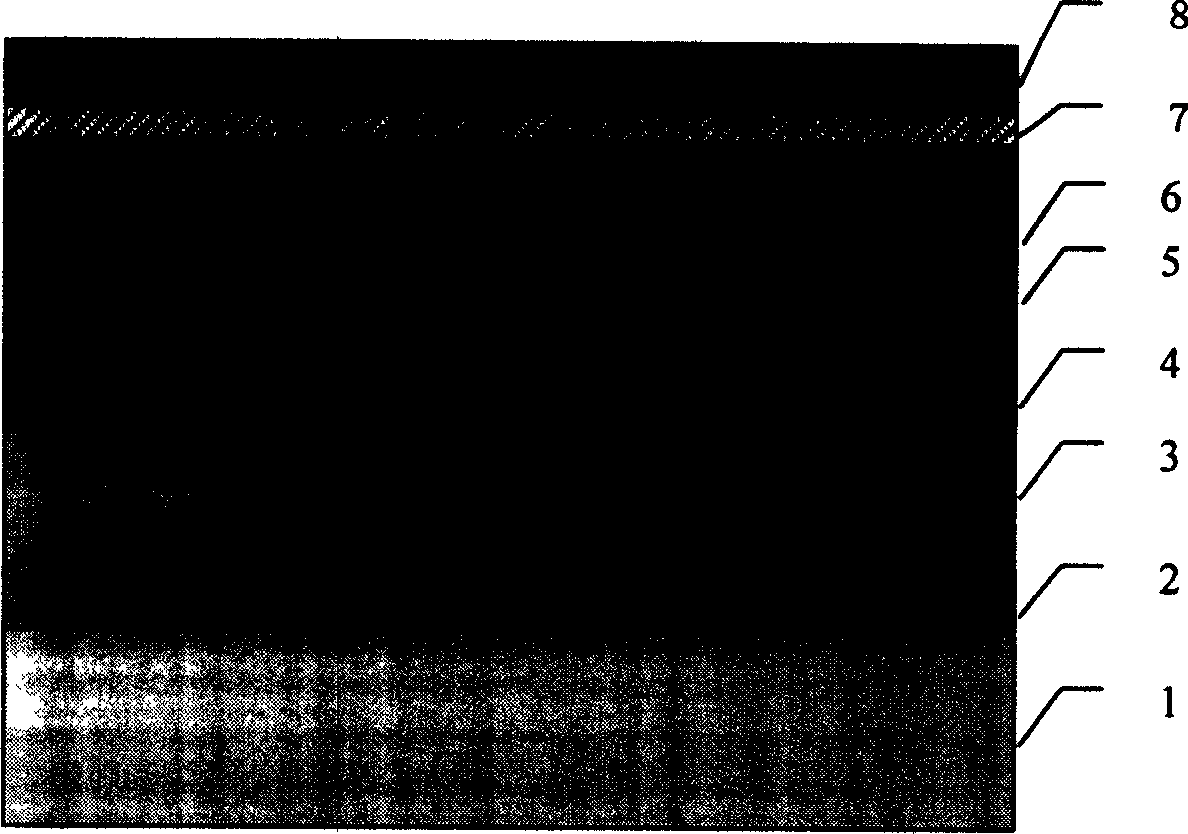

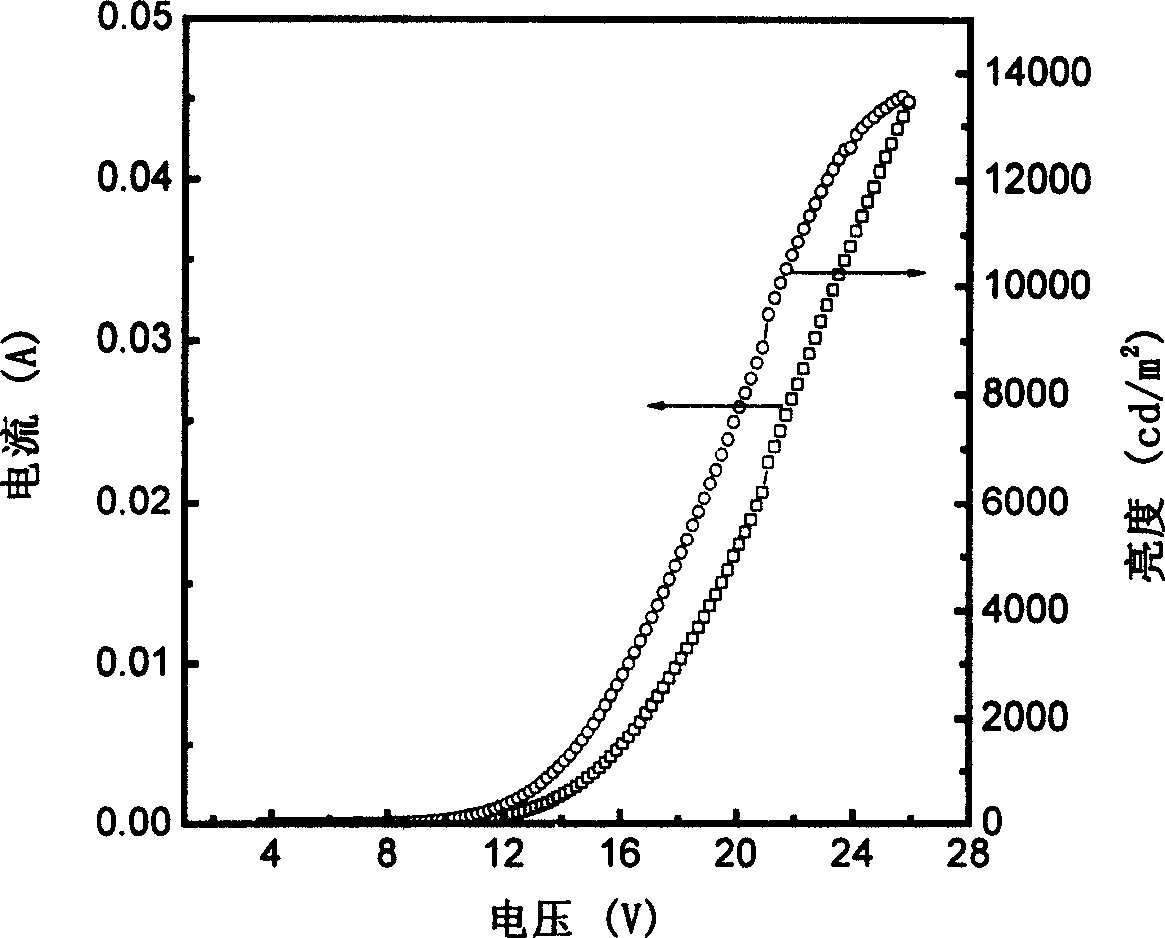

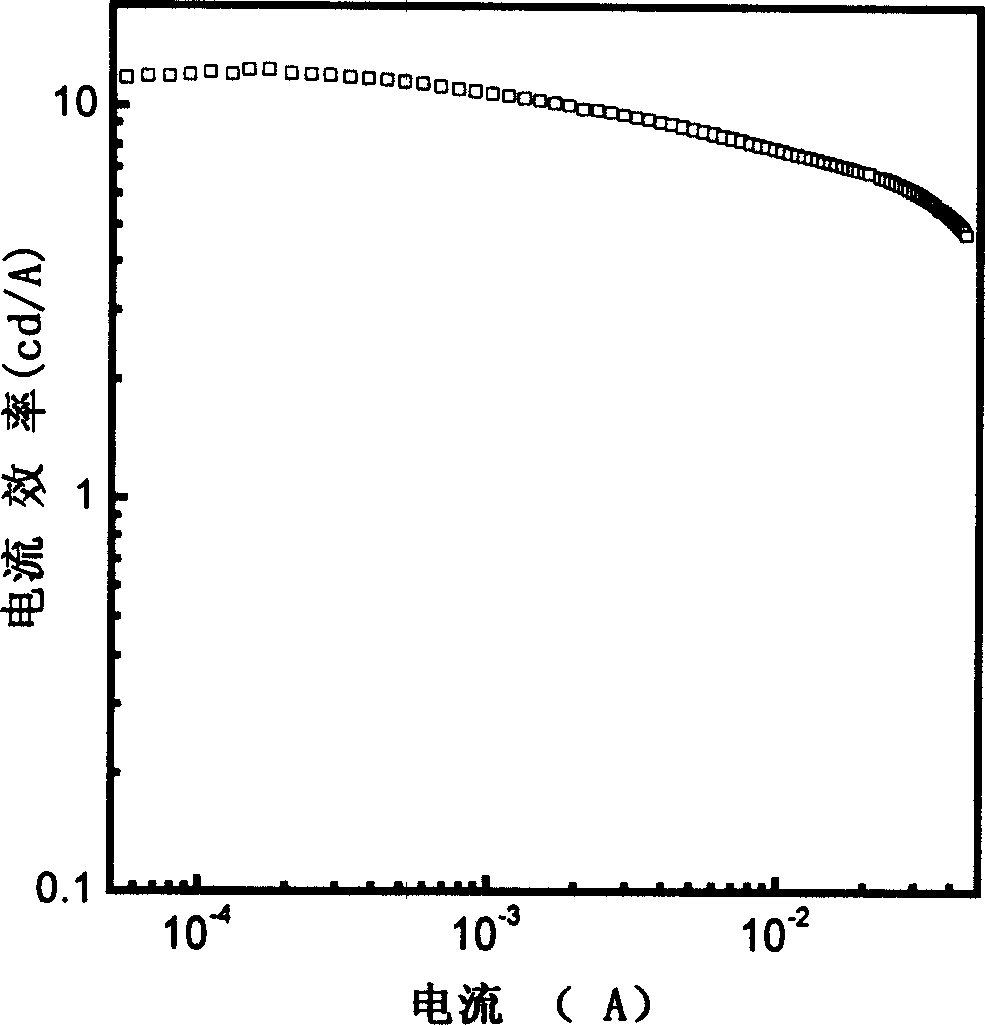

[0047] Doping DCJTB into NPB as a light-emitting layer to prepare a structure of ITO / NPB / DCJTB: NPB / NPB / DNA / BCP / Alq 3 / LiF / Al electroluminescent device, in a vacuum of 10 -4 Evaporate the organic and metal electrode layers under the pressure of Pa, the evaporation rate of the organic layer is controlled at 2 Å / s, the evaporation rate of LiF is controlled at 0.5 Å / s, the evaporation rate of the metal is controlled at 5 Å / s, and the doping concentration Controlled at 1%, among them, NPB layer thickness is 25-30nm, DCJTB: NPB layer is 8-10nm, NPB layer is 4-6nm, DNA layer is 4-5nm, BCP layer is 9-10nm, Alq 3 The thickness of the LiF layer is 25-30nm, the thickness of the LiF layer is 0.8-1.5nm, and the thickness of the Al layer is 80-100nm. The obtained device is driven by DC voltage, and white light can be obtained. The maximum efficiency is 10.3cd / A, and the maximum brightness is 10800cd / m 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com