Aluminium wheel casting plant for automobile

A technology of wheels and automobiles, which is applied in the direction of casting equipment, configuration of indicating equipment/measuring equipment, manufacturing tools, etc., and can solve problems such as bending of guides, high power consumption, and lack of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

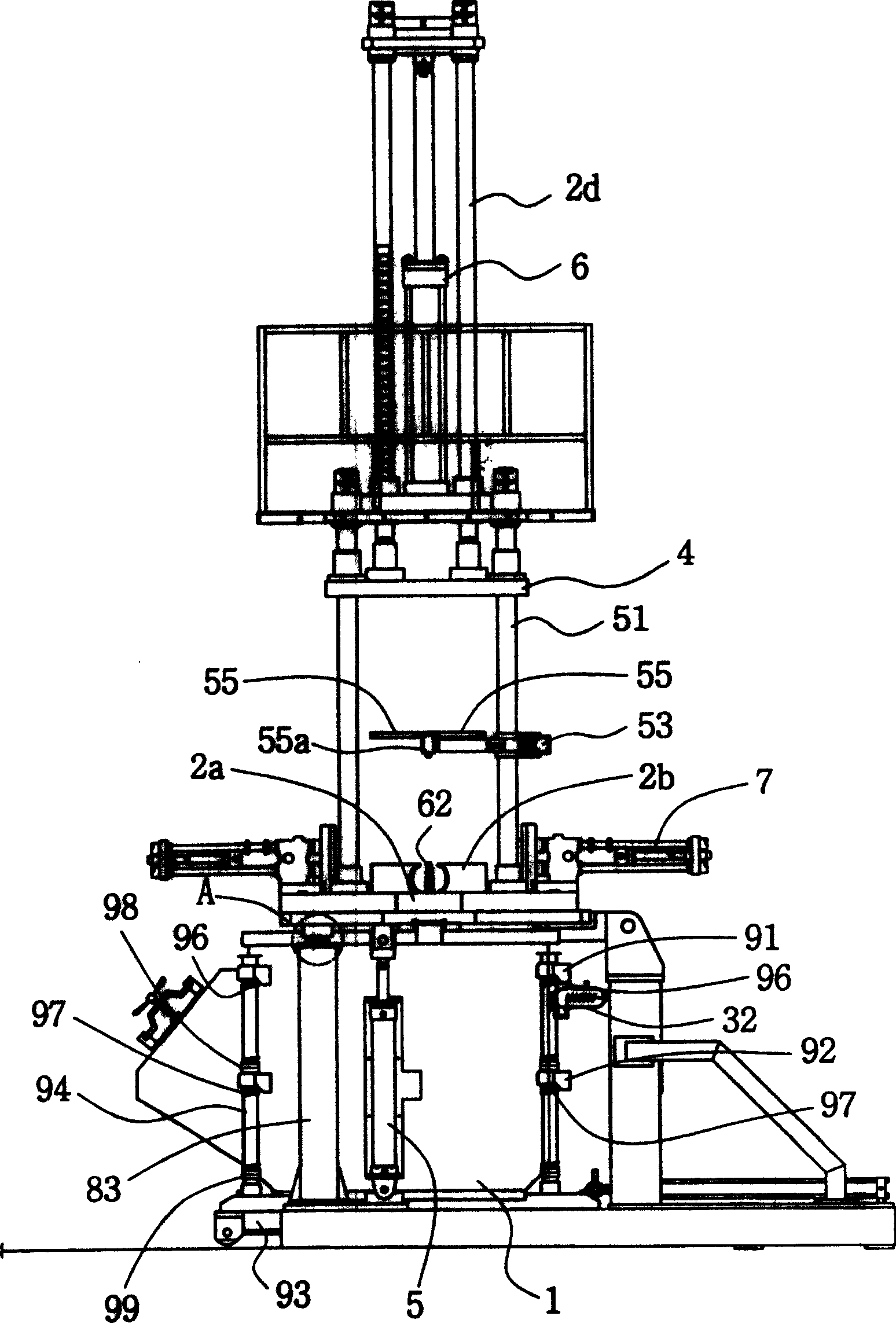

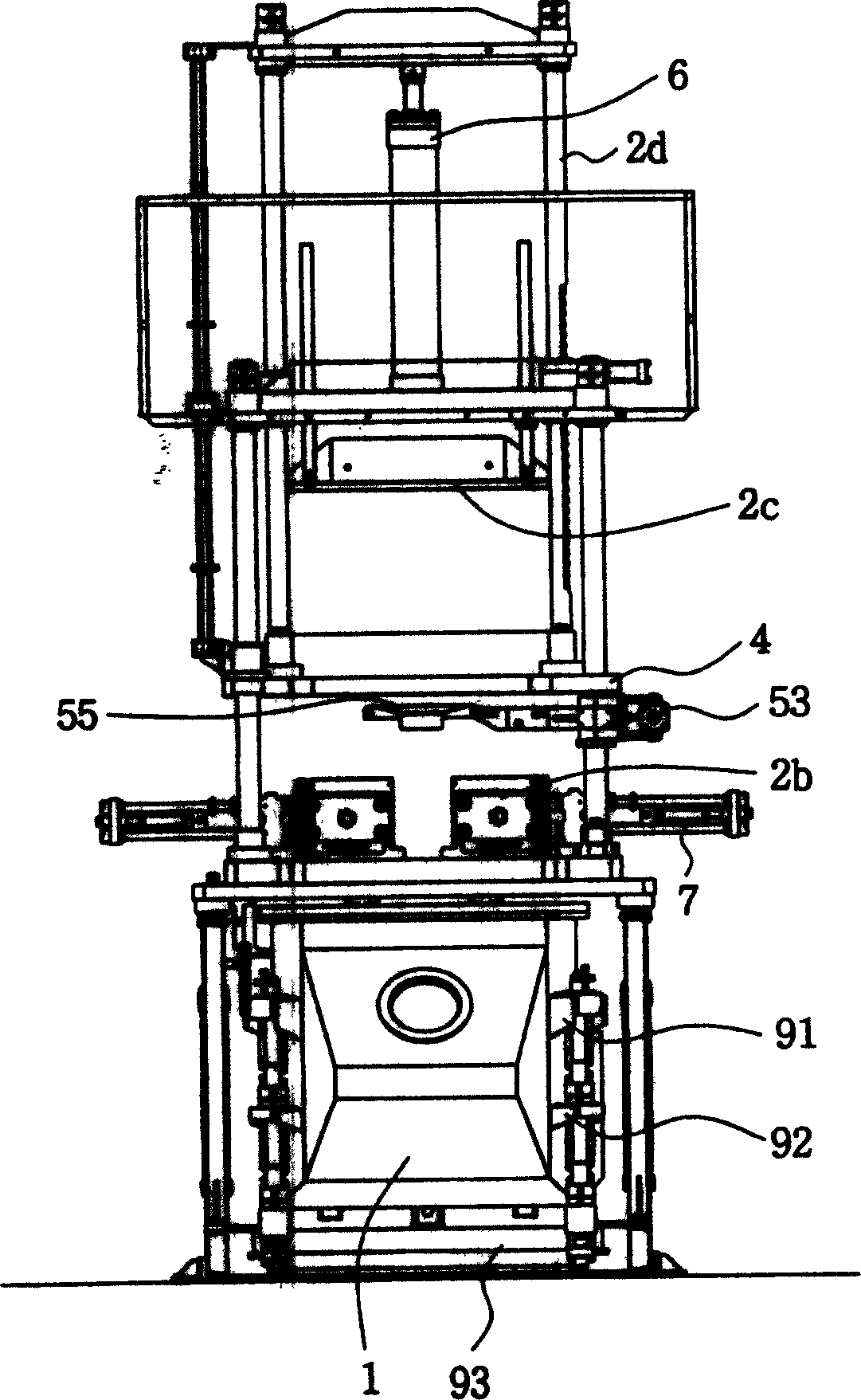

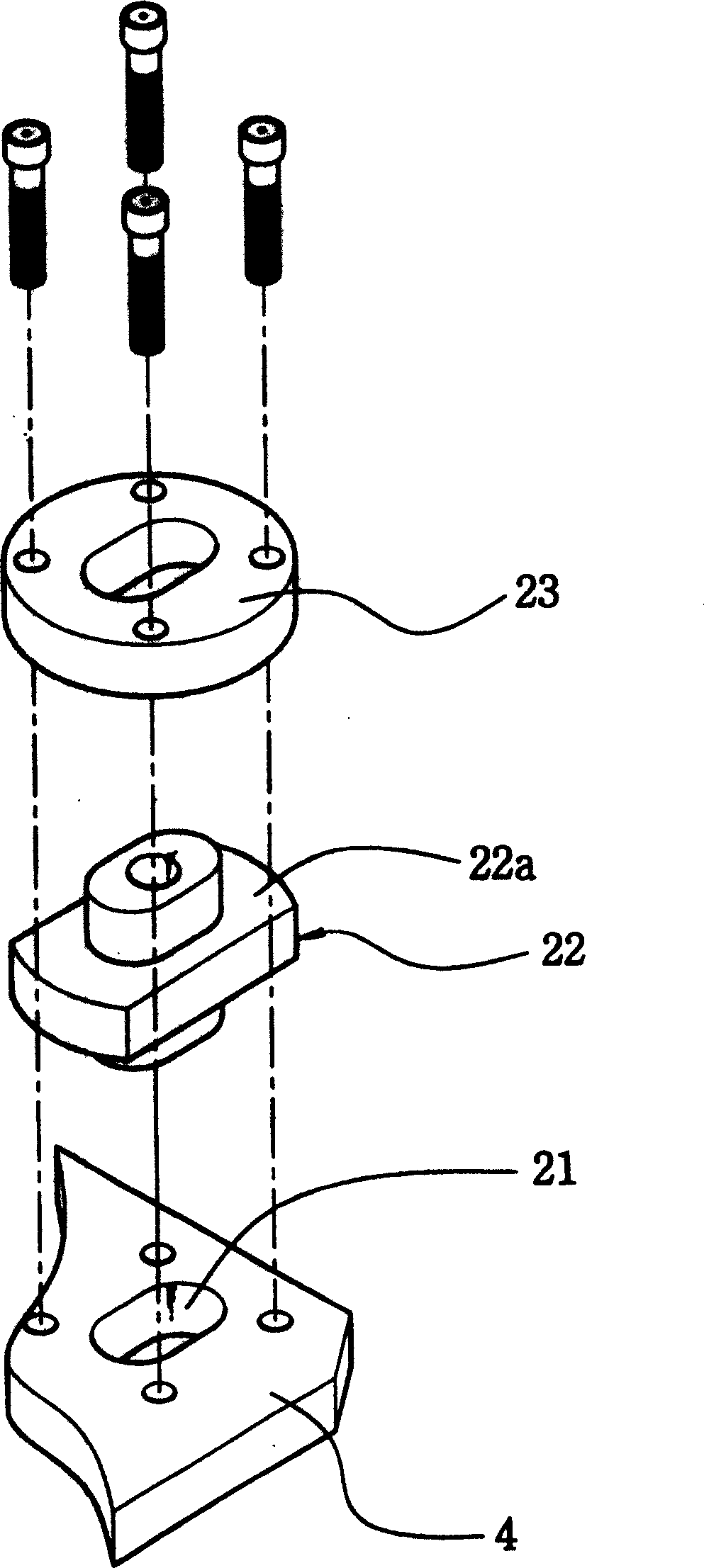

[0032] Referring to the accompanying drawings, such as Figure 1 to Figure 11 As shown, in the aluminum wheel casting device for automobiles, the casting device can cast aluminum wheels through the pressure of the side mold 2b and the upper mold 2c, and the molten aluminum in the constant heat welding furnace is forced into the bottom mold through the tube After 2a, this upper mold 2c is raised together with the movable plate 4 through the first lifting shaft 3, which is supplied with compressed air through a compressor and equipped with a casting port 1a; characterized in that:

[0033] A heat change absorber is formed for preventing the bending phenomenon of the first elevating shaft 3 by absorbing the heat change in the horizontal direction of the movable plate 4;

[0034] A preheater is formed for preheating the compressed air supplied to the constant heat welding furnace 1 by utilizing the waste heat of the side wall of the constant heat welding furnace;

[0035] A liner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com