Equipment and method for picking electronic component

A technology of electronic components and equipment, applied in the field of picking equipment, can solve problems such as difficult detection of optical systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

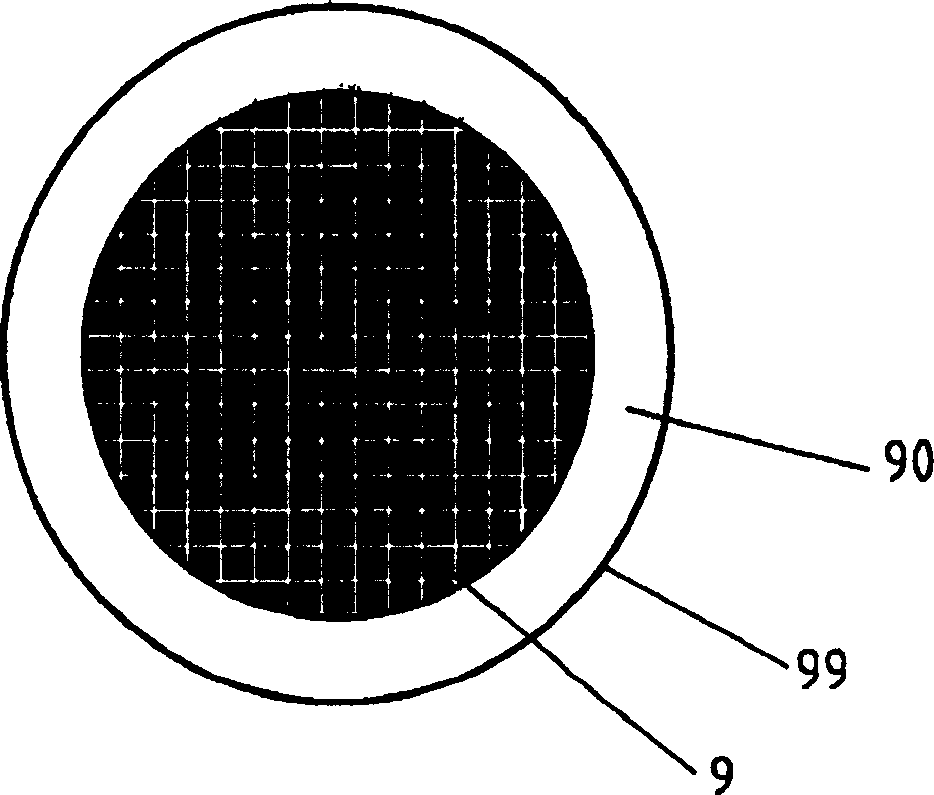

[0026] According to the preferred embodiment of the present invention, pick-up equipment is particularly suitable for from being bonded on the flexible film 90, then cut so that be divided into on the wafer 9 of individual element ( image 3 ) to extract electronic components, for example, electronic components such as LLP. The elastic membrane 90 is preferably stretched over the frame 99 to maximize the separation of the electronic components from each other.

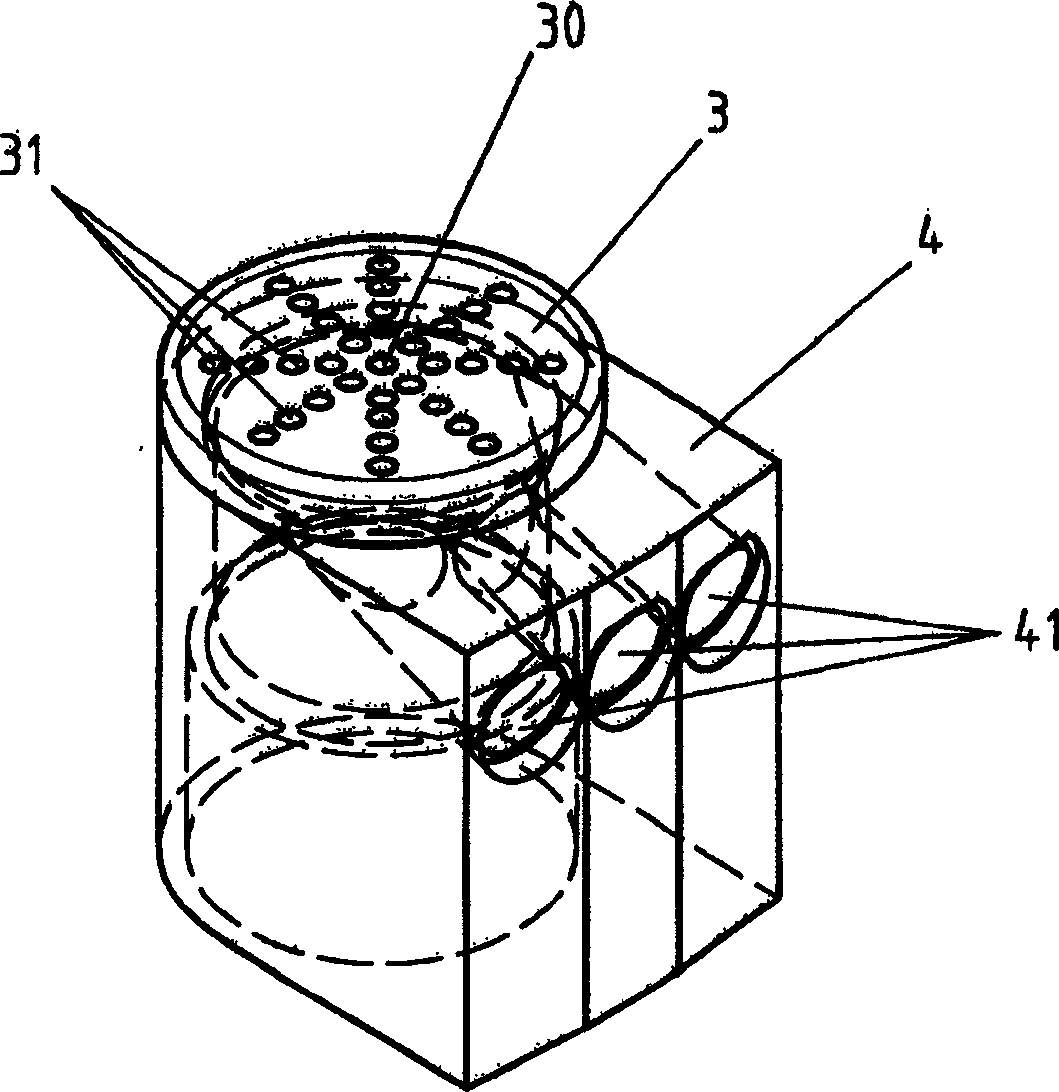

[0027] Picking device of the present invention, in figure 1 The upper part is shown, comprising the needle 2, which is held approximately vertically, with its tip pointing upwards within a seat 25 (eg cylindrical). Needle 2 is movable along its longitudinal axis. Its base 21 slides preferably via bearings 252, which mounts keep it in a perfectly rectilinear trajectory. The movement of the needle 2 is driven by a motor (not shown), for example by a linear drive or by a rotary cylinder motor associated with a mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com