Thin film transistor, active matrix substrate, display device and electronic equipment

A technology of thin film transistors and display devices, applied in the direction of transistors, circuits, electrical components, etc., can solve problems such as difficulty in ensuring reliability, reduction in retention characteristics, reduction in liquid crystal capacitance and pixel area, etc., to achieve high reliability and ensure reliability , The effect of reducing the number of wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

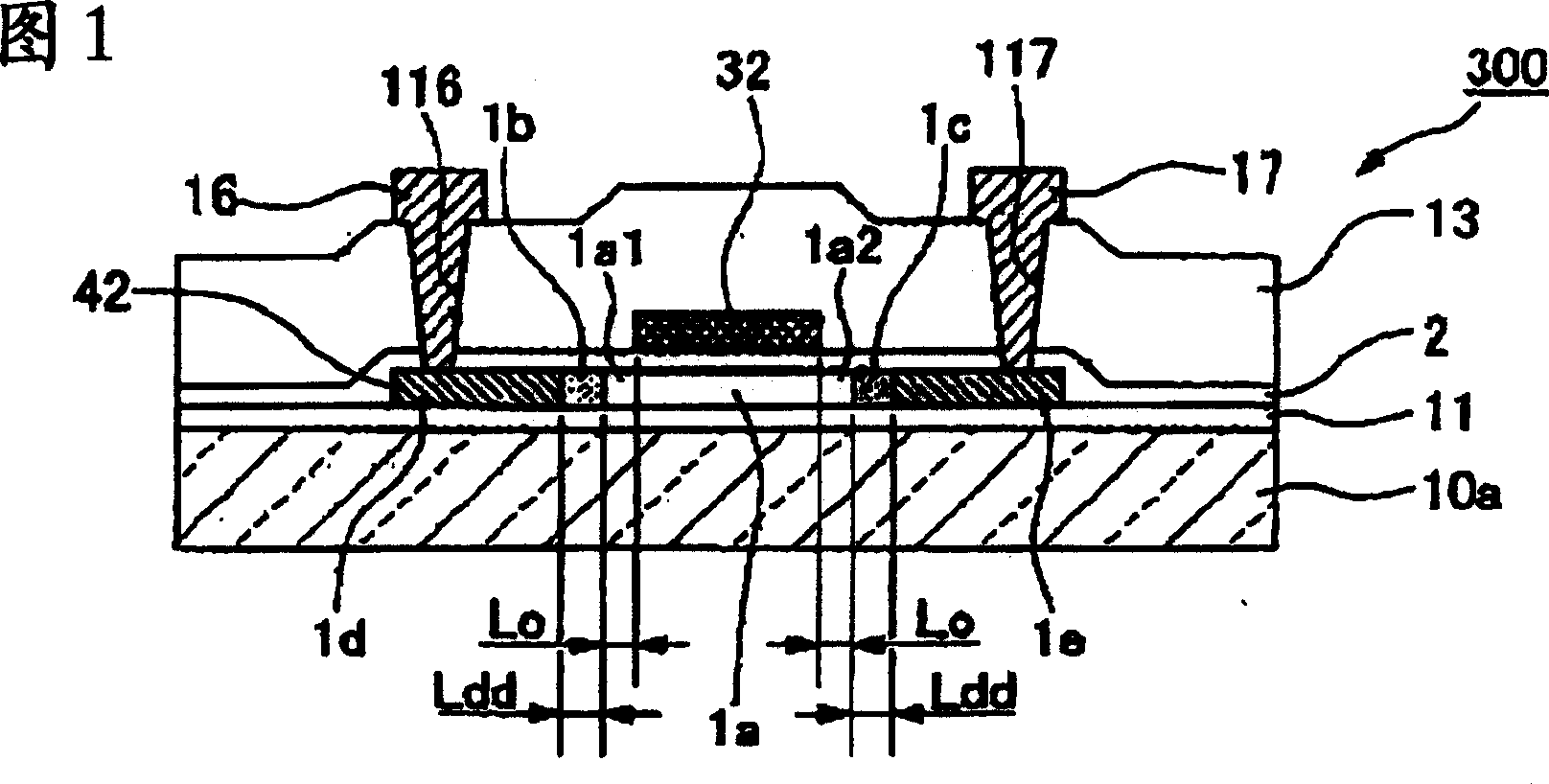

[0054] FIG. 1 is a cross-sectional view showing a first embodiment of the thin film transistor of the present invention. The TFT 300 shown in FIG. 1 is composed of a semiconductor layer 42 made of polysilicon formed on a substrate main body 10a made of an insulating material such as glass or quartz with an insulating base film 11 interposed therebetween, and an insulating film (gate electrode) formed to cover the semiconductor layer 42 . The insulating film) 2, the gate electrode 32, the source electrode 16, and the drain electrode 17 are mainly constituted.

[0055] The semiconductor layer 42 has a channel region 1a facing the gate electrode 32, compensation regions 1a1 and 1a2 connected to the channel region 1a, a low-concentration source region 1b and a low-concentration drain region 1c, a high-concentration source region 1d, and a low-concentration drain region 1c. High-concentration drain region 1e.

[0056] The above-mentioned channel region 1a and compensation region 1...

Embodiment 2

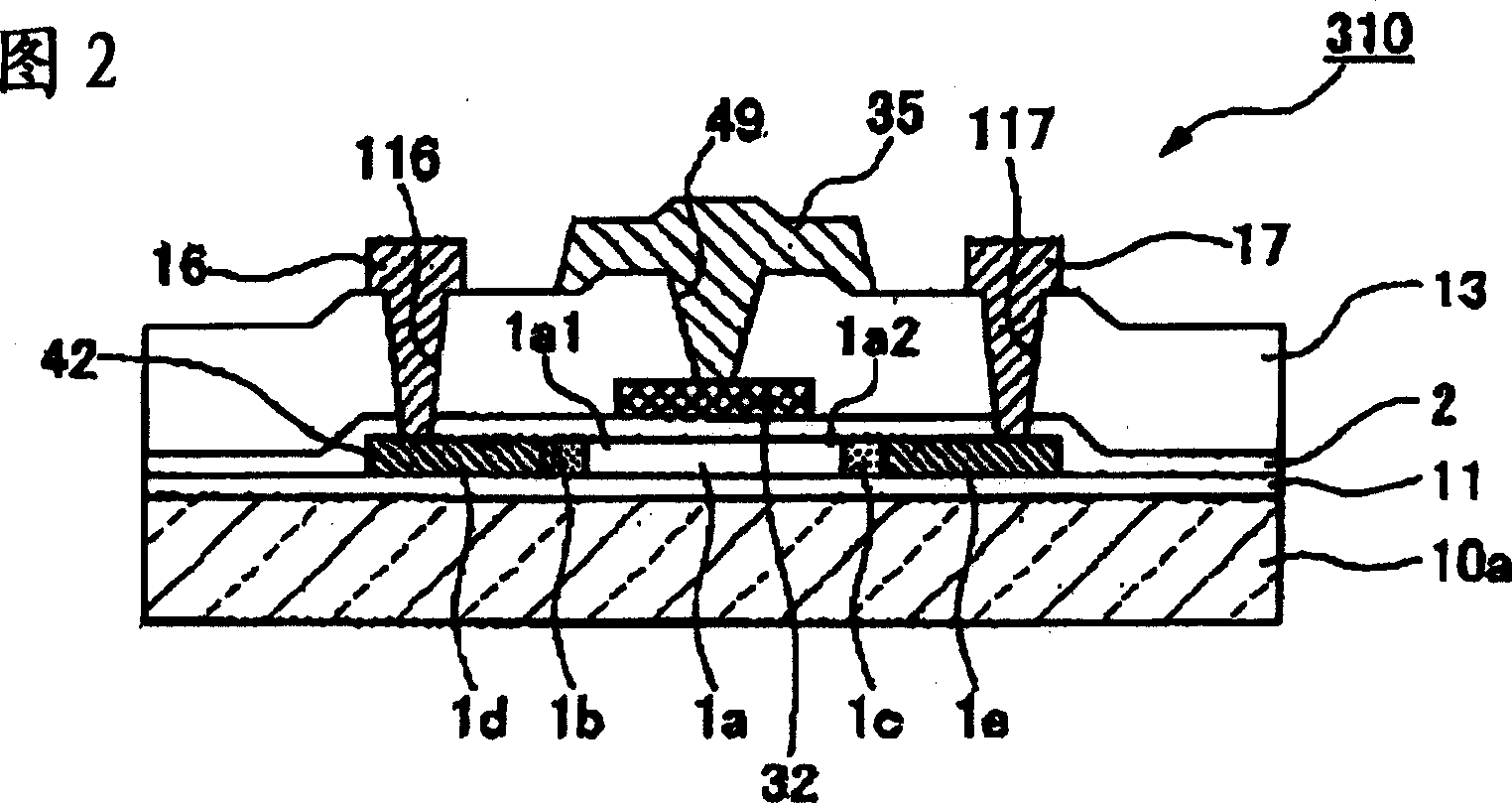

[0069] Fig. 2 is a cross-sectional view showing a second embodiment of the thin film transistor of the present invention. TFT (Thin Film Transistor) 310 shown in FIG. 2 has a structure in which wing-shaped gate electrode (second gate electrode) 35 having a substantially T-shaped cross section electrically connected to gate electrode 32 is provided relative to TFT 300 shown in FIG. 1 . Such a wing-shaped gate electrode 35 is formed to cover the gate electrode 32 on the semiconductor layer 42 and the compensation regions 1a1 and 1a2 of the semiconductor layer 42 in plan view. In this embodiment, the left-right direction of the wing-shaped gate electrode 35 is The edge ends are located in the planar regions of the low-concentration drain region 1 c and the low-concentration source region 1 b of the semiconductor layer 42 . Furthermore, the wing-shaped gate electrode 35 is electrically connected to the gate electrode 32 through a contact hole 49 provided through the first interlay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com