Method for producing lithium secondary battery and lithium secondary battery produced by the method

A manufacturing method and lithium storage battery technology, which is applied in the manufacture of electrolyte storage batteries, lithium storage batteries, secondary batteries, etc., can solve problems such as complex equipment, deviations between batteries, and affecting battery performance, and achieve economical and easy manufacturing. and the effect of uniform composition and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0026] Production of battery cells for lithium storage batteries

[0027] (1) Preparation of separation membrane membrane

[0028] 9 g of PVDF-HFP copolymer (88:12)-KynarFLEX 2801 (Atochem) and 100 ml of acetone were put into the container, and the temperature was maintained at 45°C while stirring, and the polymer was dissolved in the solvent. Among them, 10 g of dibutyl phthalate as a plasticizer and 1 g of fumed silica were added, and stirring was continued for 30-60 minutes while maintaining the above temperature to obtain a uniformly dispersed solution. The mixture is coated on the surface-treated PET film with a coater, and dried in a drying zone. The film thickness at this time reached 45 microns.

[0029] (2) Preparation of cathode film

[0030]10 g of PVDF-HFP copolymer (88:12)-KynarFLEX 2801 (Atochem) and 100 ml of acetone were put into the container, and the temperature was maintained at 45°C while stirring, and the polymer was dissolved in the solvent. Among them, 16 g...

Embodiment 1

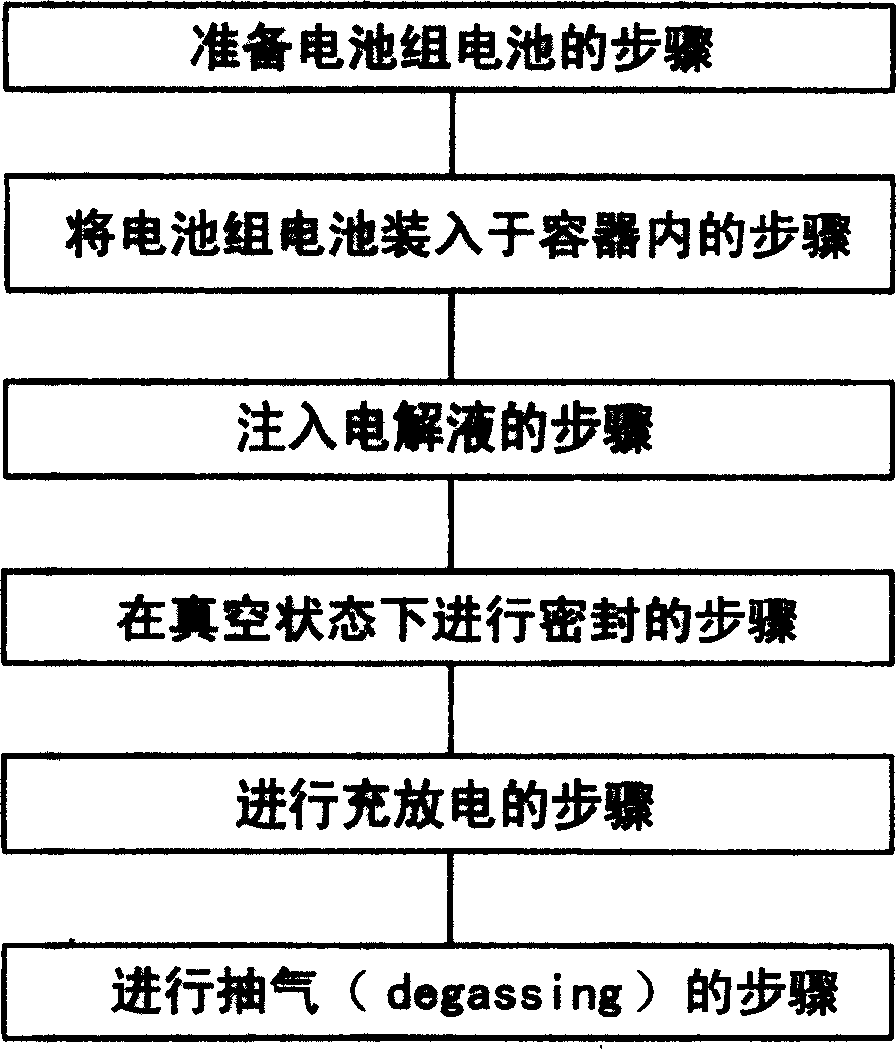

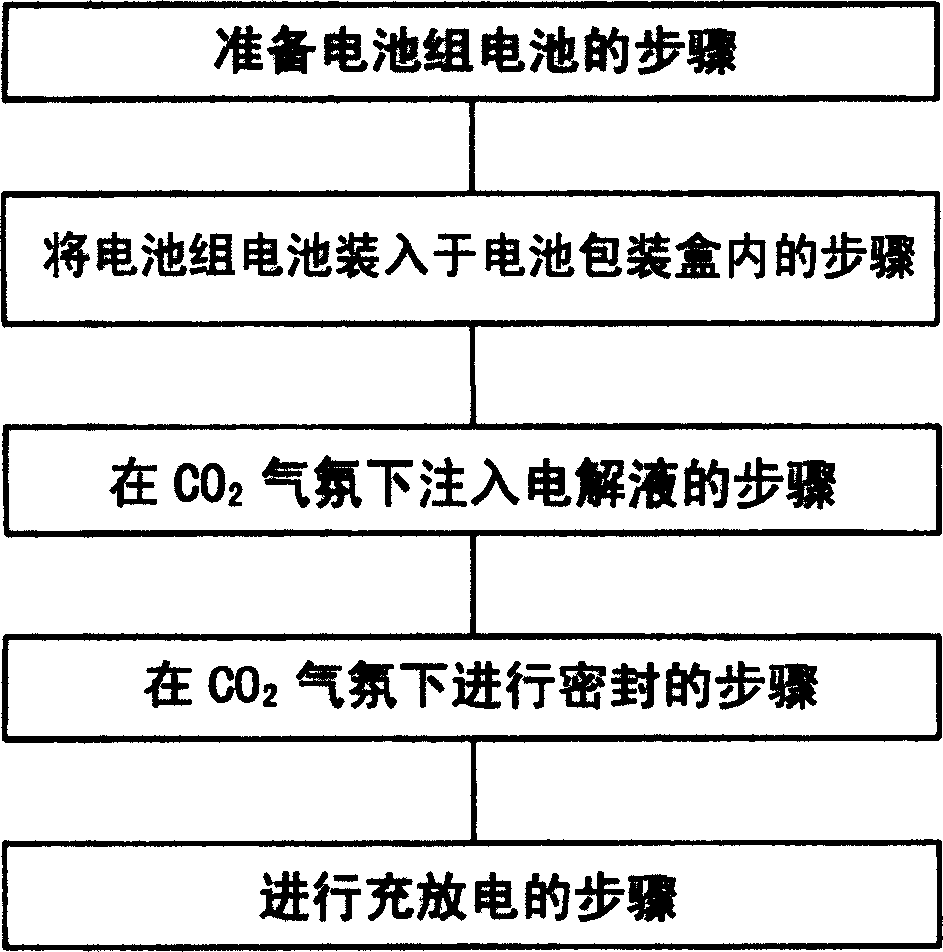

[0046] Production of lithium storage battery of the present invention

[0047] The battery cell manufactured by the manufacturing example 1 was prepared. Put the battery cell in an aluminum laminate box and store it in dry CO with a dew point temperature of -40°C or less 2 An electrolyte was injected into the aluminum laminate box under an atmosphere. After that, dry CO with a dew point temperature of -40°C or less 2 Heat up to 180℃ and 2kgf / cm are applied to the battery in the atmosphere 2 Pressure, and was sealed. After sealing, the battery was charged and discharged three times at a voltage of 3.0-4.2V, and thus a lithium secondary battery was manufactured.

experiment example 1

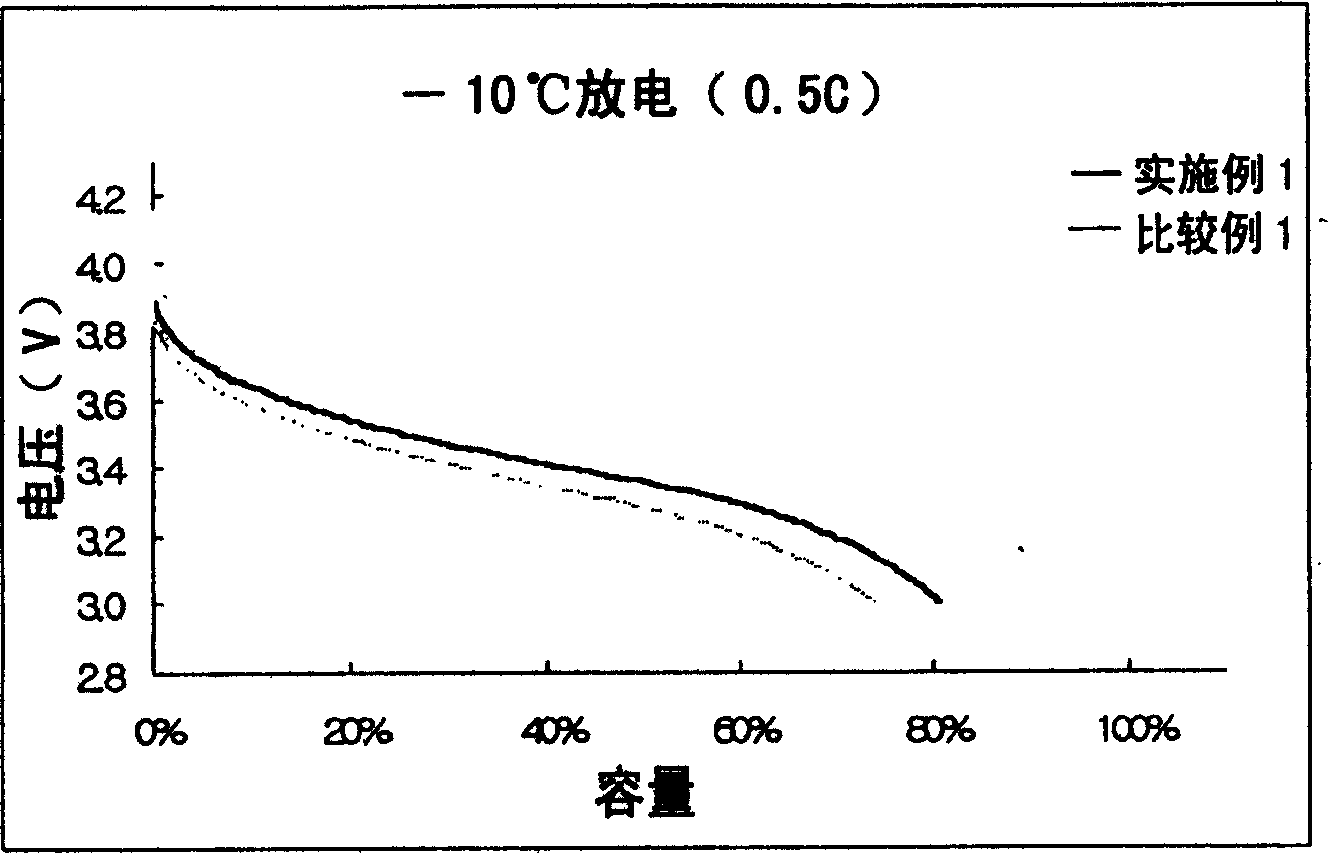

[0054] Measurement of discharge capacity and appearance

[0055] (1) Measuring method of discharge capacity at -10℃

[0056] The batteries manufactured in the Examples and Comparative Examples were charged to 4.2V with a current of 0.5C at normal temperature, and after being left at -10°C for 4 hours, they were discharged at 0.5C, and their capacity was measured. The results are shown in Table 1.

[0057] -10℃ discharge capacity

Example 1

80.7%

Comparative example 1

74.0%

[0058] As shown in Table 1 above, the lithium secondary battery manufactured according to the manufacturing method of the present invention exhibits excellent low-temperature performance. Specifically, the low-temperature discharge capacity of Comparative Example 1 was 74.0%, and Example 1 showed a low-temperature discharge capacity of 80.7%. It can be seen that the lithium battery manufactured by the manufacturing method of the present invention increased the low-temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com